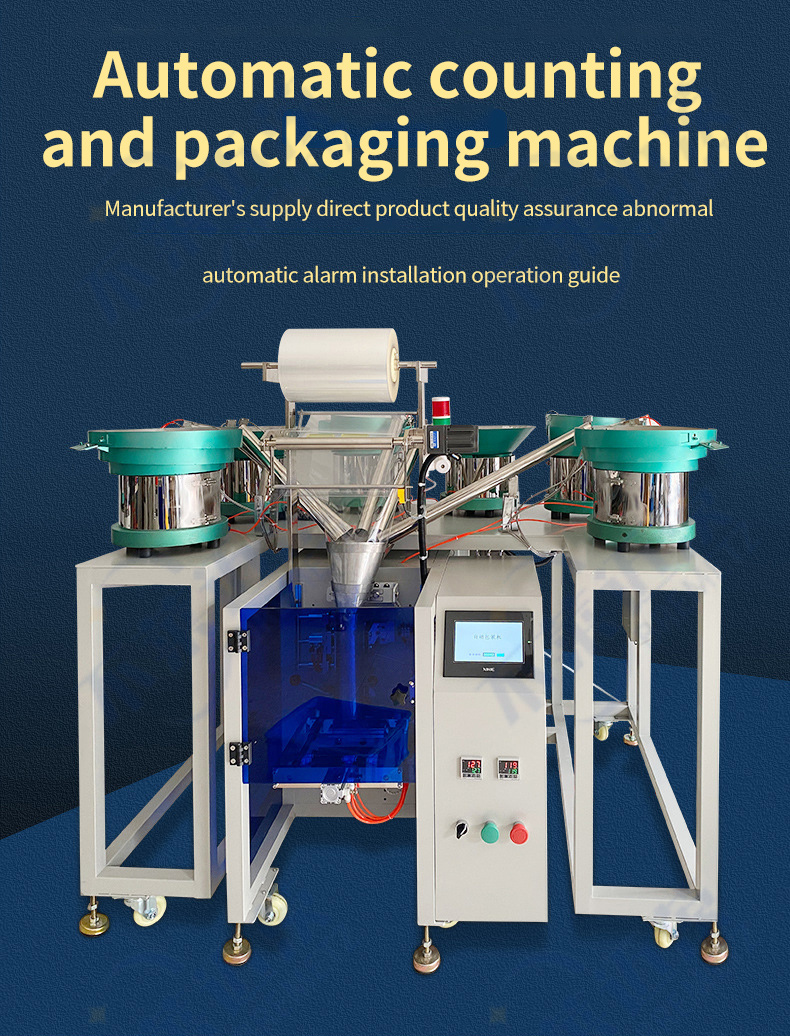

Counting Packaging Machine

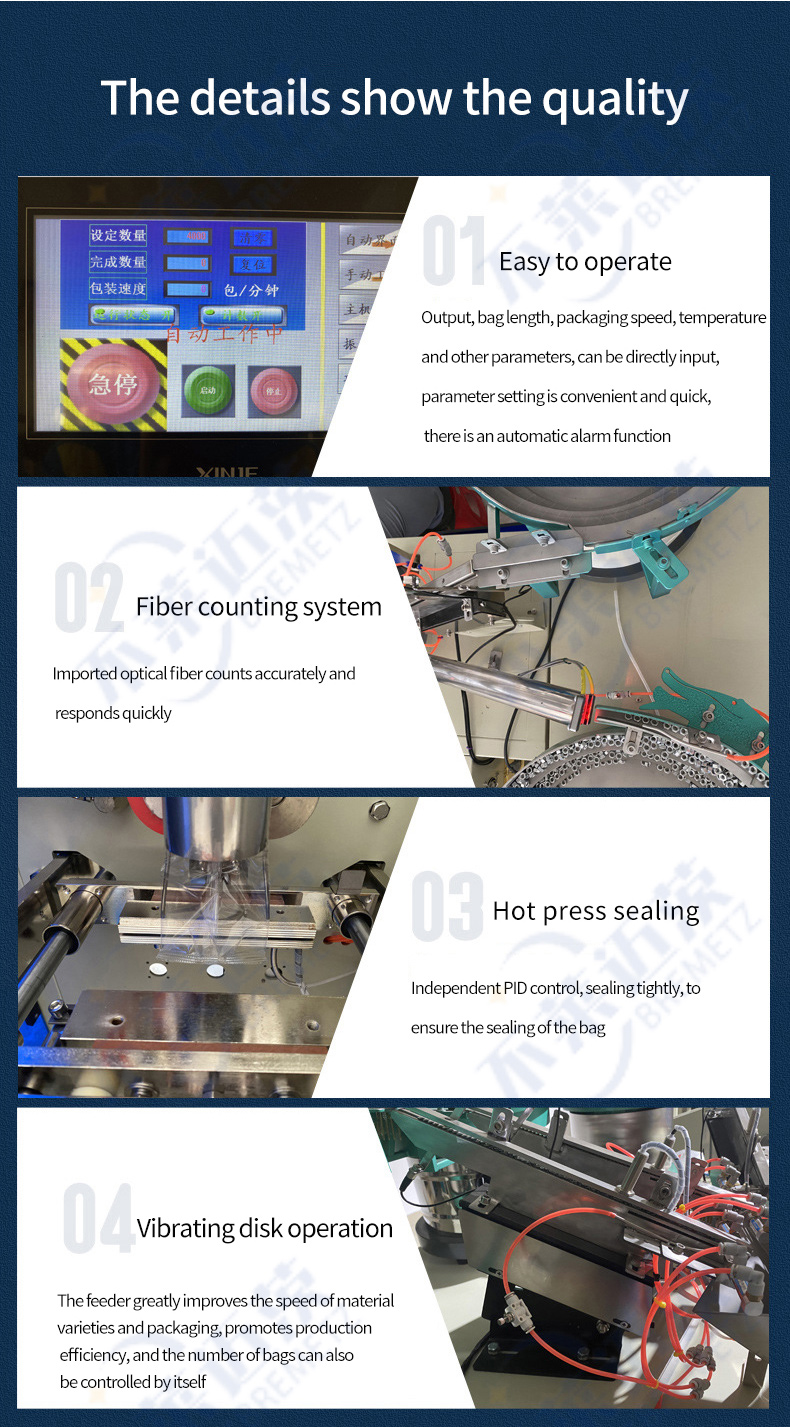

1. It uses advanced electronic counters, photoelectric sensors, visual recognition systems and other technologies to accurately count the number of products.

2. It has a high degree of automation and can complete the counting and packaging tasks of a large number of products in a short time, greatly improving production efficiency.

3. It reduces the links of manual counting and packaging, reduces the company's dependence on manpower, and thus saves a lot of labor costs.

4. The structural design of the counting and packaging machine is sturdy and durable, and is made of high-quality materials and components, which can adapt to long-term and high-intensity production operations.

5. It has automatic adjustment and calibration functions, and can be quickly set and adjusted according to different product specifications and packaging requirements, which improves the flexibility and adaptability of production.

The counting and packaging machine is an automated mechanical device that combines accurate counting and efficient packaging functions. It plays a vital role in modern industrial production and is widely used in many industries such as food, daily chemicals, hardware, electronics, etc.

High-precision counting sensors have extremely high sensitivity and response speed, and can quickly and accurately detect the passage or presence of products and convert them into electrical signals for counting processing.

Model: bremetz-6P

Powersupply Specifications: 220,50/60HZ

Bag shape: Back cover

Bag making method: Elephant trunk

Transverse seal pattern: Straight/mesh

Step electronically Film drawing method: controlled double wheel film pulling

Transverse seal pattern: Straight/mesh

Speed: 1-50 packets/min

Incision form: Tooth cut/plain cut

Packing capacity:Max500g

Roll film width: Max.260mm (customizable)

Power:1.1W

Film thickness: 5-13C (Recommended 6-8C)

Outer packing: Wooden box

Bag length: 40-150mm (touch screen adjustment)

Equipment weight: 280KG

Bag width: 50-120mm (replacement bagmaker)

Equipment size: Length 800* width 700* height 1550mm

Additional devices: Punching/venting/weighing/ screening, etc

Measurement method: Rice fiber measurement

Edge width: 8-100mm (fine adjustment)

Standard equipment: Pinhole exhaust

Material bag: OPP/CPP/PE/NILO composite /PE+PEL/AL, etc

The automated operation software has a friendly human-computer interaction interface. Operators can easily perform equipment parameter settings, operation mode selection, fault diagnosis and troubleshooting, etc. through the touch screen or operation panel.

Regardless of the shape, size, or material of the product, the counting and packaging machine can achieve high-precision counting. For tiny electronic components, the counting error can be controlled within a very small range, ensuring that the number of products in each packaging unit is accurate.

It can handle a variety of products, including solids, liquids, particles, powders and other substances in different forms, as well as items of various shapes and sizes. Whether it is round pills, square chocolates, long strips of stationery, or irregularly shaped hardware parts, they can all be counted and packaged smoothly on the counting and packaging machine.