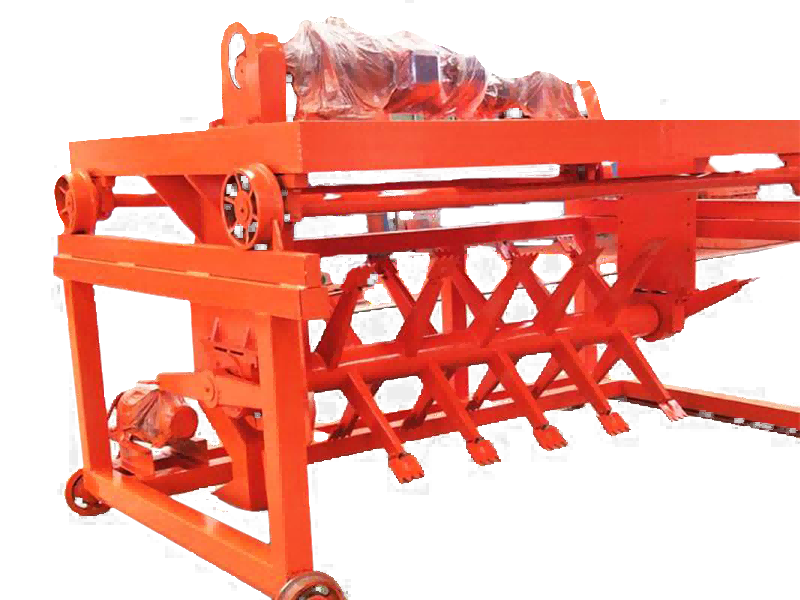

Trough type turning machine

1. Through regular turning and aeration, it can ensure that there is sufficient oxygen inside and outside the material, maintain aerobic conditions, and promote the active reproduction of beneficial microorganisms.

2. Microbial activity generates a lot of heat. The trough turning machine can evenly distribute the heat during the turning process to prevent local overheating.

3. The material in the fermentation tank is turned up and down on a cross section, which can make the material turn evenly and improve the fermentation quality.

4. The air introduced during the turning process helps to adjust the moisture content of the material and avoid the anaerobic environment caused by excessive humidity.

5. The control cabinet is centrally controlled, and manual or automatic control functions can be realized, which improves production efficiency and stability.

The trough turning machine is mainly used for the fermentation treatment of organic materials, such as livestock and poultry manure, agricultural straw, food processing waste, etc. Through mechanical turning and forced ventilation, sufficient oxygen is provided to the microorganisms in the material, accelerating the decomposition and transformation of organic matter, thereby achieving a fast and efficient fermentation process.

The unique trough structure design enables the equipment to turn the materials in all directions and in depth. The high torque drive device can easily turn over a large amount of materials.

The built-in ventilation ducts and fans can accurately control the ventilation volume and ventilation time according to the fermentation requirements. Through reasonable ventilation, not only can the temperature and humidity of the materials be adjusted, but also a suitable living environment can be provided for microorganisms.

Using advanced PLC control system, the operator only needs to set relevant parameters on the control panel, such as turning time, ventilation frequency, etc., and the equipment can automatically complete operations such as turning and ventilation of materials.

At the same time, the equipment also has fault alarm and automatic protection functions. Once an abnormal situation occurs, it can shut down in time and sound an alarm, making it convenient for maintenance personnel to investigate and handle it, ensuring the safe and stable operation of the equipment.