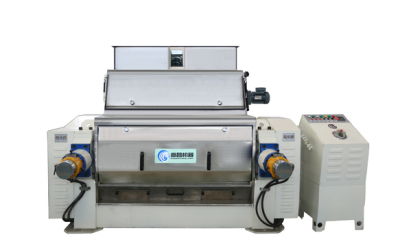

Roulette Turning Machine

1. Wide application range: can be used for turning over a variety of fermentation raw materials.

2. High turning efficiency: greatly reduce manpower consumption, shorten turning time, and optimize fermentation environment.

3. Large span and high depth: width can reach 33 meters and depth can reach 3 meters.

4. Double wheel disc, can be raised and lowered, easy to operate, CNC control wheel lifting.

5. There is no dead angle in turning over, manual control, to ensure thorough turning over.

The wheel compost turner, also known as the wheel compost turner, is a large-scale organic fertilizer composting equipment. Compared with the trough compost turner and the walking compost turner, the wheel compost turner does not have too high requirements on the fermentation form. In addition, as a multifunctional composting equipment, the wheel compost turner is suitable for the fermentation composting of poultry and livestock manure, sludge garbage, sugar factory filter mud, dregs cake and straw sawdust.

The wheel is symmetrically turned over, and the turning is done without dead angles under the displacement of the speed-adjusting shifting trolley, which can fully turn the material over, make the material fully contact with the air, accelerate the fermentation process, and improve the fermentation quality. At the same time, the turning depth and span are large, which can meet the turning needs of materials of different scales and depths. For example, the turning depth can reach 1.5-3 meters, and the maximum turning width can reach 30 meters.

Low energy consumption: It adopts a unique energy-saving and efficient transmission mechanism, which greatly reduces energy consumption and saves energy costs under the same workload compared to traditional flipping equipment.

Strong adaptability: It can be applied to many different types of organic waste and materials, and can have a good turning effect on materials with different humidity, viscosity and particle size. It is not limited by the shape of the material pile and the site, and has strong versatility and adaptability.

Stable and reliable operation: Due to its reasonable structure, key components are made of high-quality materials, and have undergone strict quality inspection and debugging, the equipment runs stably, has a low failure rate, a long service life, and can work stably for a long time, reducing the cost of equipment maintenance and replacement.