Automatic Telescopic Conveyor

1. High degree of automation: Through advanced control systems, fully automated operations such as material conveying and telescopic functions are achieved without a lot of manual intervention, improving production efficiency.

2. Accurate metering and filling: The metering system equipped with high-precision sensors and intelligent algorithms can accurately measure and fill materials of different forms with a very small error range.

3. Flexible telescopic: Its telescopic function can be easily achieved through buttons or other control methods, and the length of the conveyor can be quickly adjusted according to the actual working scene.

4. Efficient conveying: With high conveying speed and stable operating performance, it can complete the task of conveying a large amount of materials in a short time.

5. Improve safety: Reduce direct contact between workers and materials and the intensity of manual handling, and reduce the risk of work-related accidents caused by manual operation.

6. Versatility: Supports a variety of conveying methods and packaging forms. In addition to conventional material conveying, it can also be used in conjunction with other packaging equipment or production equipment.

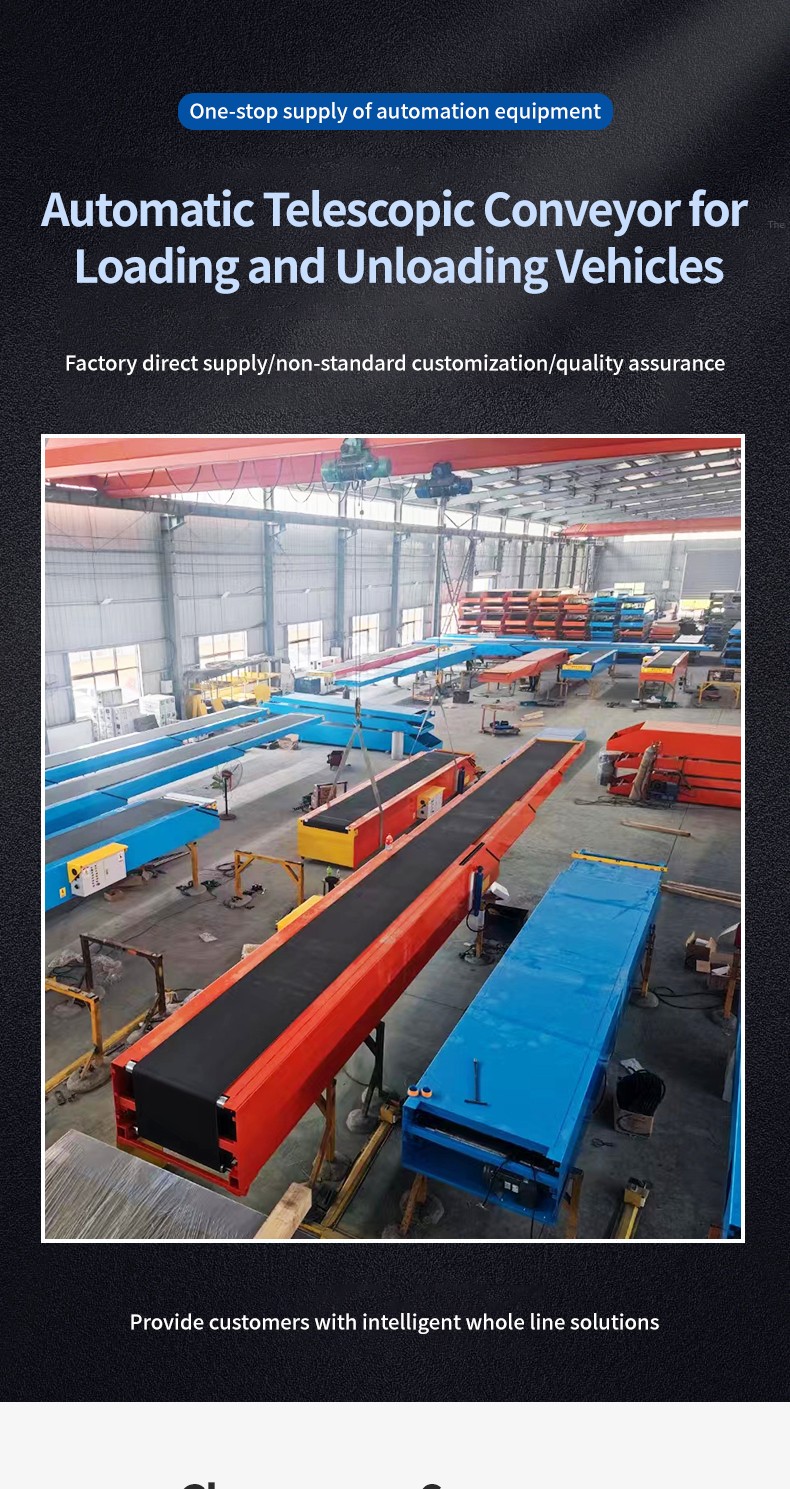

Automatic Telescopic Conveyor is a material conveying equipment that integrates automatic control and flexible telescopic functions, designed to meet the needs of efficient, convenient and accurate material conveying in different scenarios. With its advanced technology and practical design, it is widely used in many industries such as logistics, warehousing, manufacturing, e-commerce, food, and medicine, and has become an indispensable part of modern material handling systems.

Efficient transportation: With stable transportation speed and flexible telescopic function, it can quickly and accurately transport materials to designated locations, effectively improve material flow efficiency, shorten loading, unloading, and handling time, especially in the logistics and warehousing process, which can significantly speed up the entry and exit of goods. library speed and improve overall operational efficiency.

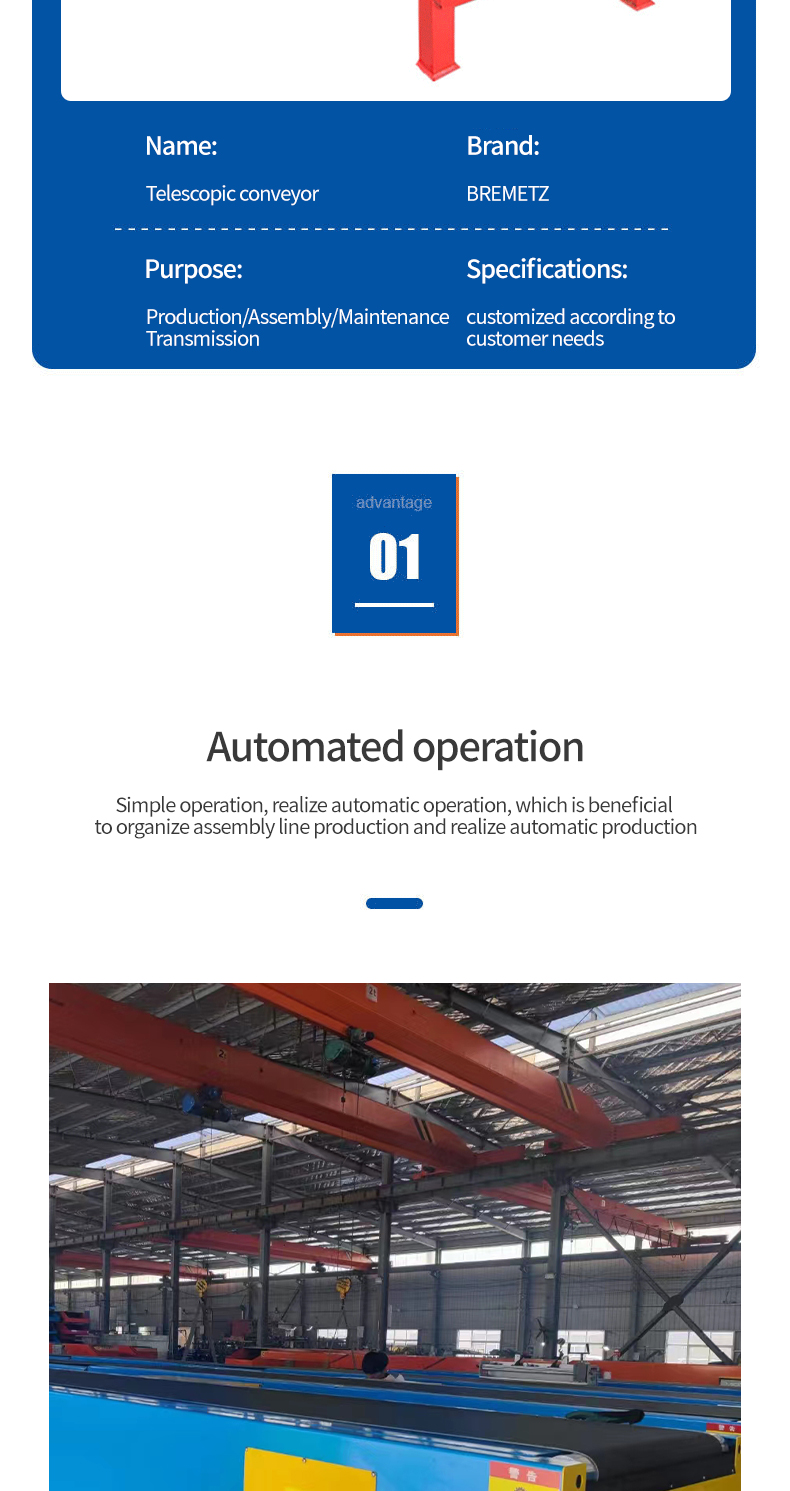

Name:Telescopic conveyor

Brand:BREMETZ

Purpose:Production/Assembly/Maintenance

Specifications: customized according to Transmission customer needs

Automated operation,Simple operation, realize automatic operation, which is beneficial to organize assembly line production and realize automatic production.

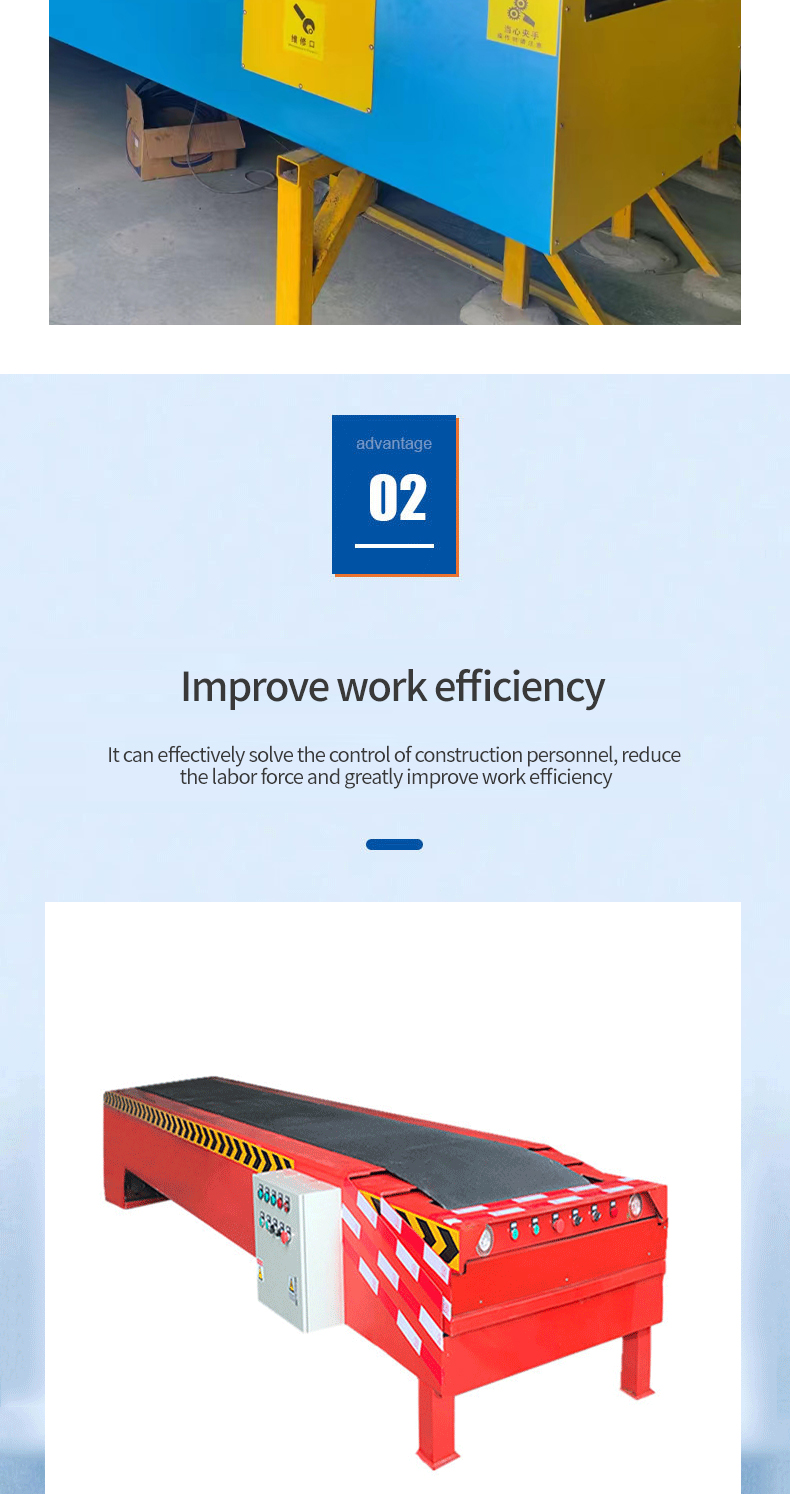

Improve work efficiency,It can effectively solve the control of construction personnel, reduce the labor force and greatly improve work efficiency.

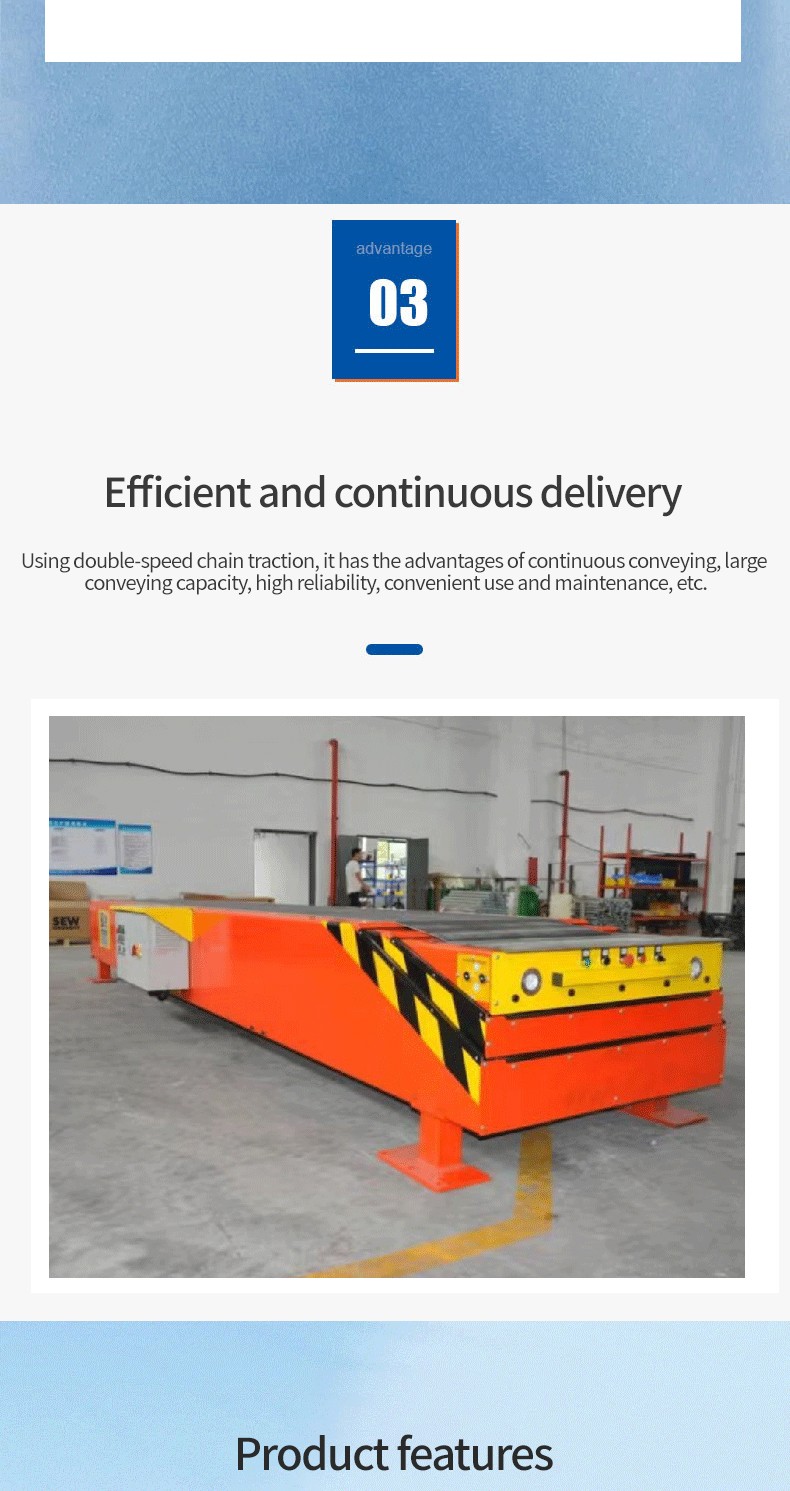

Efficient and continuous delivery,Using double-speed chain traction, it has the advantages of continuous conveying, large conveying capacity, high reliability, convenient use and maintenance, etc.

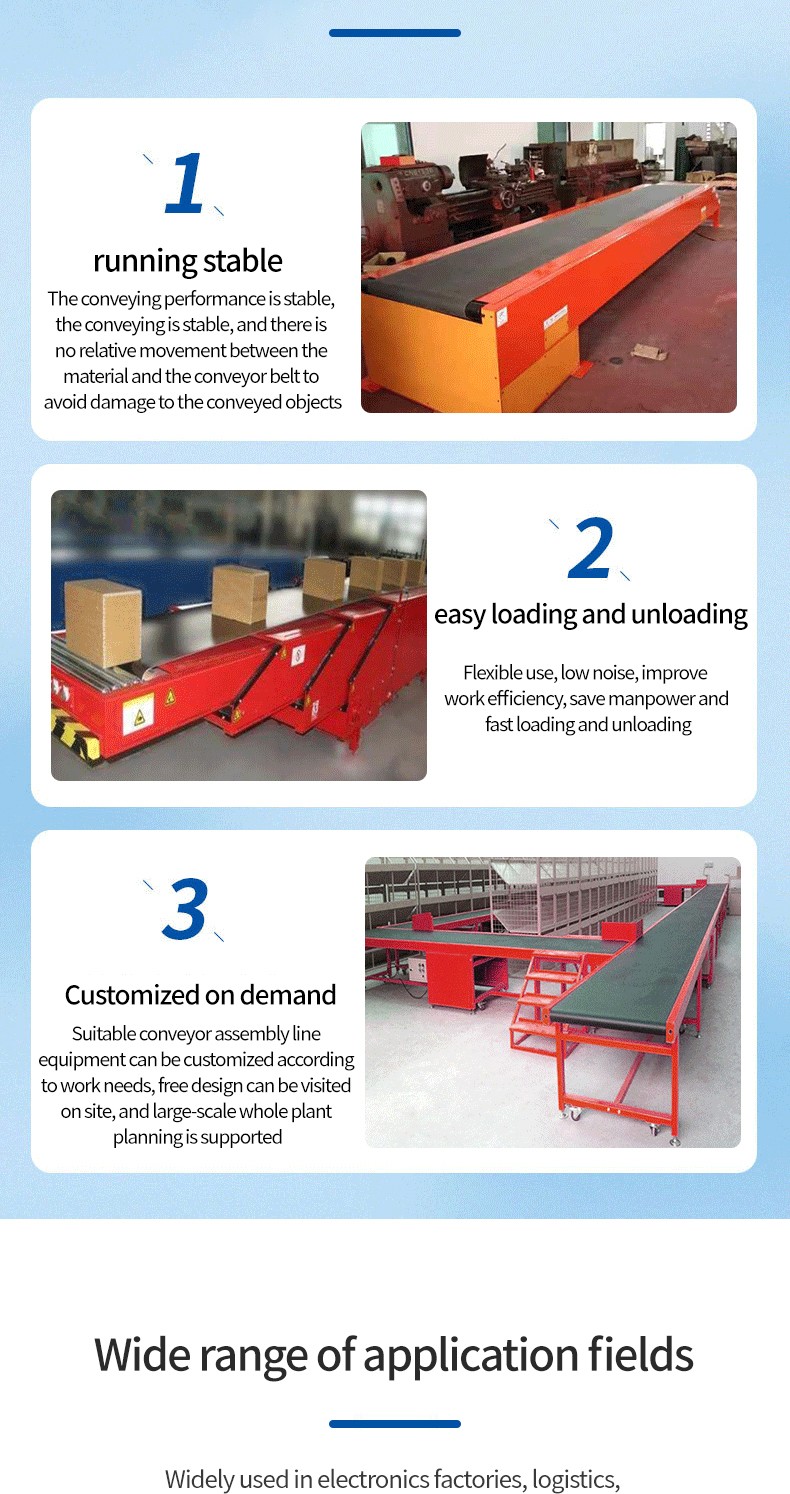

Running stable,The conveying performance is stable, the conveying is stable, and there is no relative movement between the material and the conveyor belt to avoid damage to the conveyed objects.

Easy loading and unloading,Flexible use, low noise, improve work efficiency, save manpower and fast loading and unloading.

Customized on demand,Suitable conveyor assembly line equipment can be customized according to work needs, free design can be visited on site, and large-scale whole plant planning is supported.

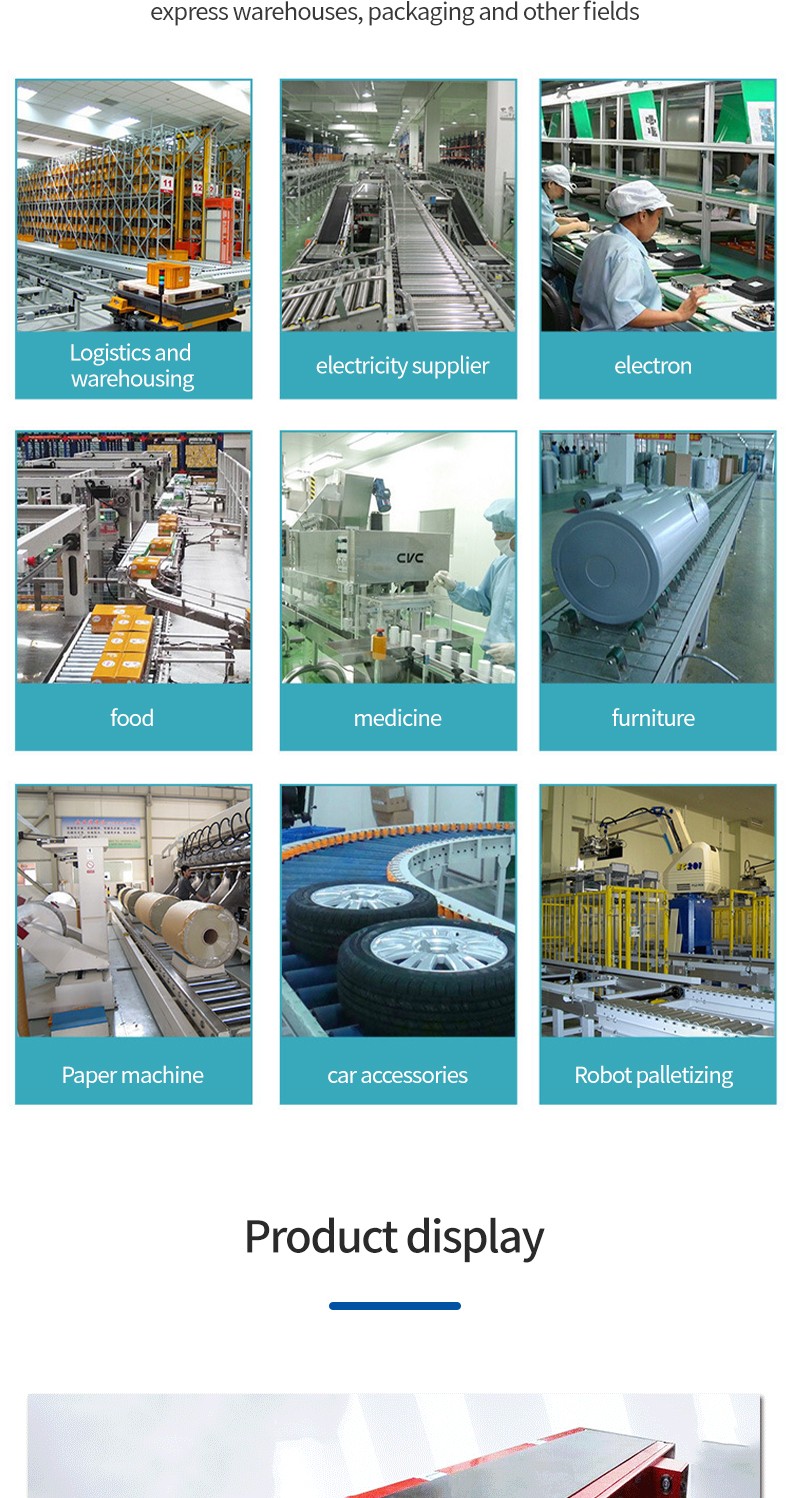

Wide range of application fields,Widely used in electronics factories, logistics.

Applicable industries:

Logistics and warehousing industry: used for loading and unloading, sorting, storage and other links of goods in logistics centers, express warehouses, and other places.

Manufacturing industry: on the production lines of various factories, raw materials, semi-finished products, and finished products are accurately transported between different processing stations.

Food industry: transport food raw materials, finished packaged foods, etc., and the appropriate conveying speed and method can be selected according to the characteristics of the food.

Pharmaceutical industry: used to transport pharmaceutical raw materials, intermediates and finished drugs, strictly complying with the requirements of pharmaceutical production quality management standards.

E-commerce industry: to meet the needs of rapid sorting and transportation of packages, the packages are accurately transported to the corresponding stations through automatic telescopic conveyors.

Our professional technical team will provide on-site installation services, perform precise installation according to site conditions and equipment requirements, and conduct comprehensive debugging after installation to ensure the normal operation of all equipment functions, accurate conveying and telescopic movements, and optimize and adjust relevant parameters based on the user's actual material conveying needs.

Provide users with operation training and maintenance training. Experienced engineers will guide operators on-site to familiarize themselves with the equipment's operation interface, parameter settings, daily maintenance points, and methods for handling common faults.

We continue to pay attention to the development of industry technology, provide users with technical upgrade services for equipment in a timely manner, and continuously improve the performance, functions and intelligence level of equipment through software updates, hardware improvements, etc., so that the equipment always maintains advanced performance and meets the growing business needs of users.