Corn puffing production equipment

1. High yield: Able to process a large amount of corn raw materials in a short time and produce a large amount of puffed corn products.

2. Continuous operation: The equipment runs stably and can work continuously for a long time, reducing the time waste caused by equipment shutdown, preheating, etc., and greatly improving production efficiency.

3. Good puffing effect: The corn can be fully puffed to form a uniform porous structure, with a crisp taste and easy digestion and absorption. The volume of the puffed corn increases and the density decreases, which is convenient for storage, transportation and use.

4. High nutrient retention: During the puffing process, although there will be a certain temperature increase, due to the short puffing time and the design of the equipment can better control the temperature and pressure, the nutrients in the corn can be retained to the greatest extent.

5. High food safety: Through the process of high-temperature puffing and instantaneous decompression, bacteria, mold and other microorganisms in the corn, as well as harmful substances such as parasite eggs, can be effectively killed, improving the safety of the product.

6. High degree of automation: Most modern corn puffing production equipment is equipped with advanced automatic control systems. The operator only needs to perform simple settings and operations, and the equipment can automatically complete a series of production processes such as feeding, puffing, and discharging.

7. High energy utilization rate: The equipment adopts advanced heating and transmission technology, which can effectively utilize energy and reduce energy consumption.

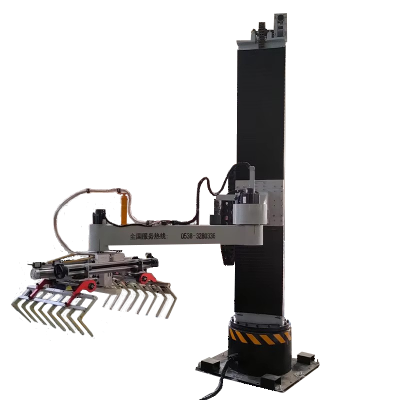

Corn puffing production equipment is an advanced mechanical equipment specially used to process corn raw materials into puffed corn products. It combines modern food processing technology with mechanical manufacturing technology, can meet the needs of corn puffing processing for enterprises of different sizes and production scenarios, and is widely used in food industry, feed processing and other fields.

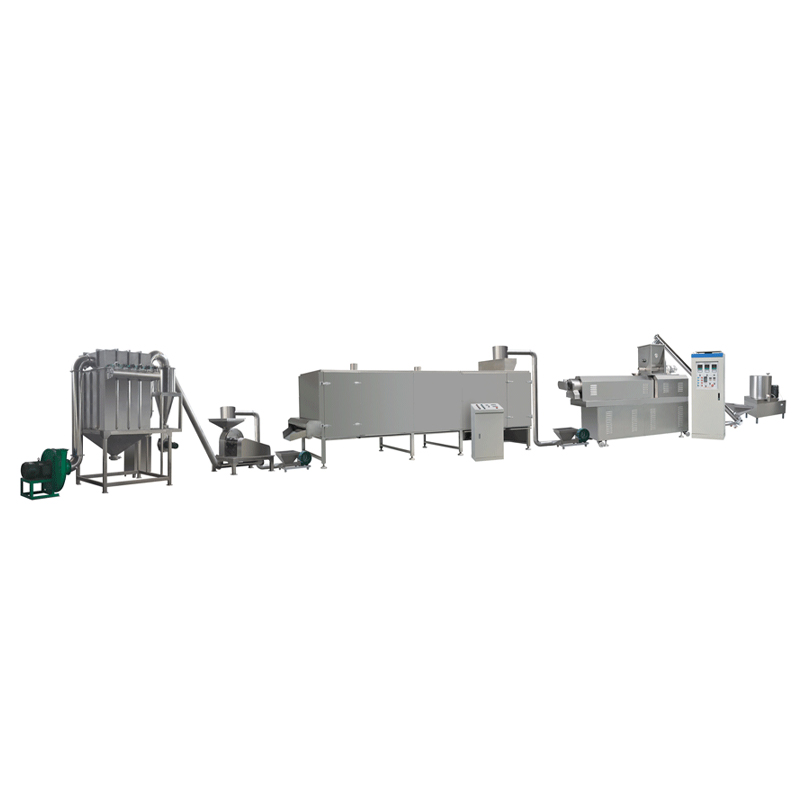

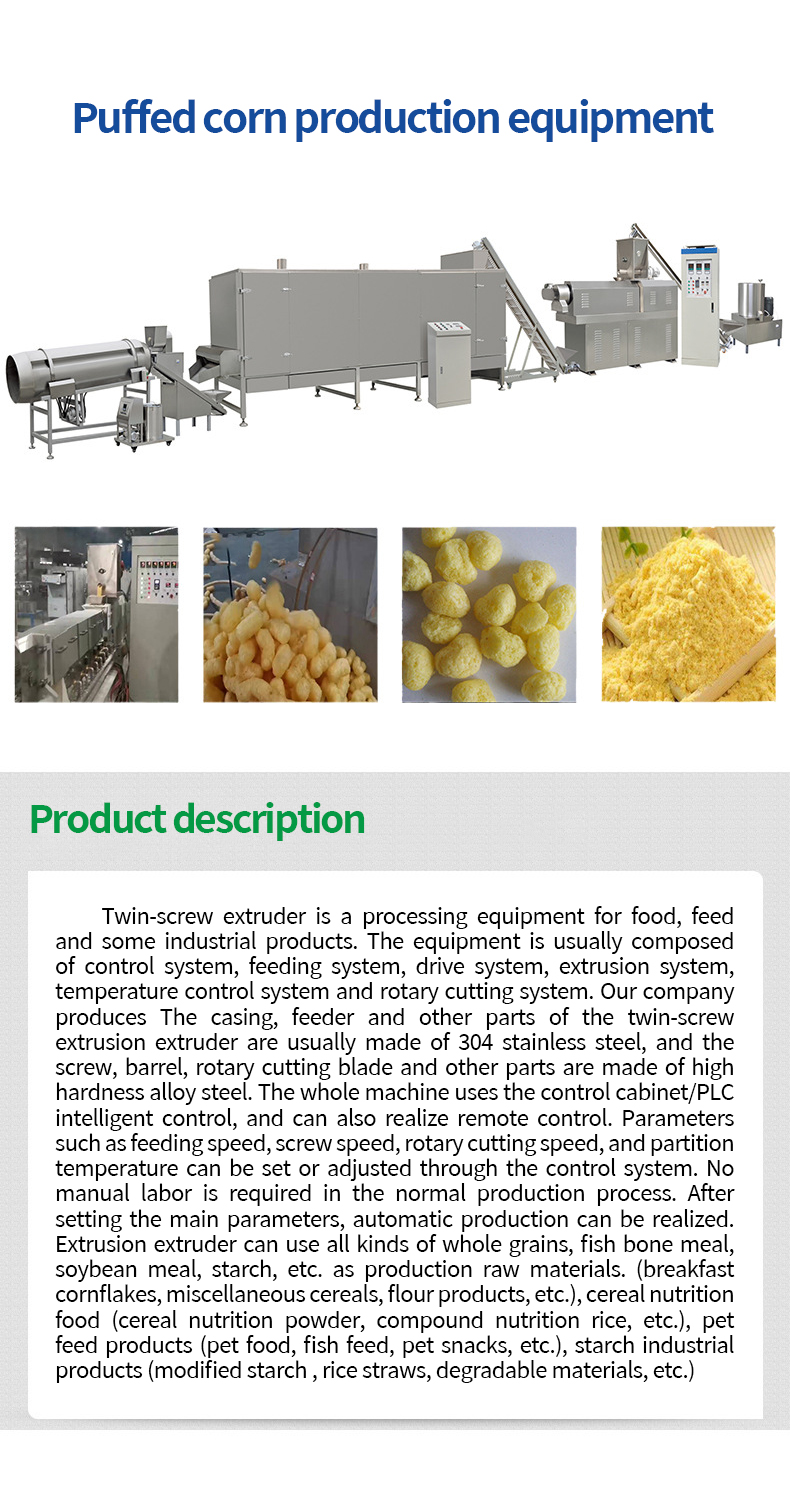

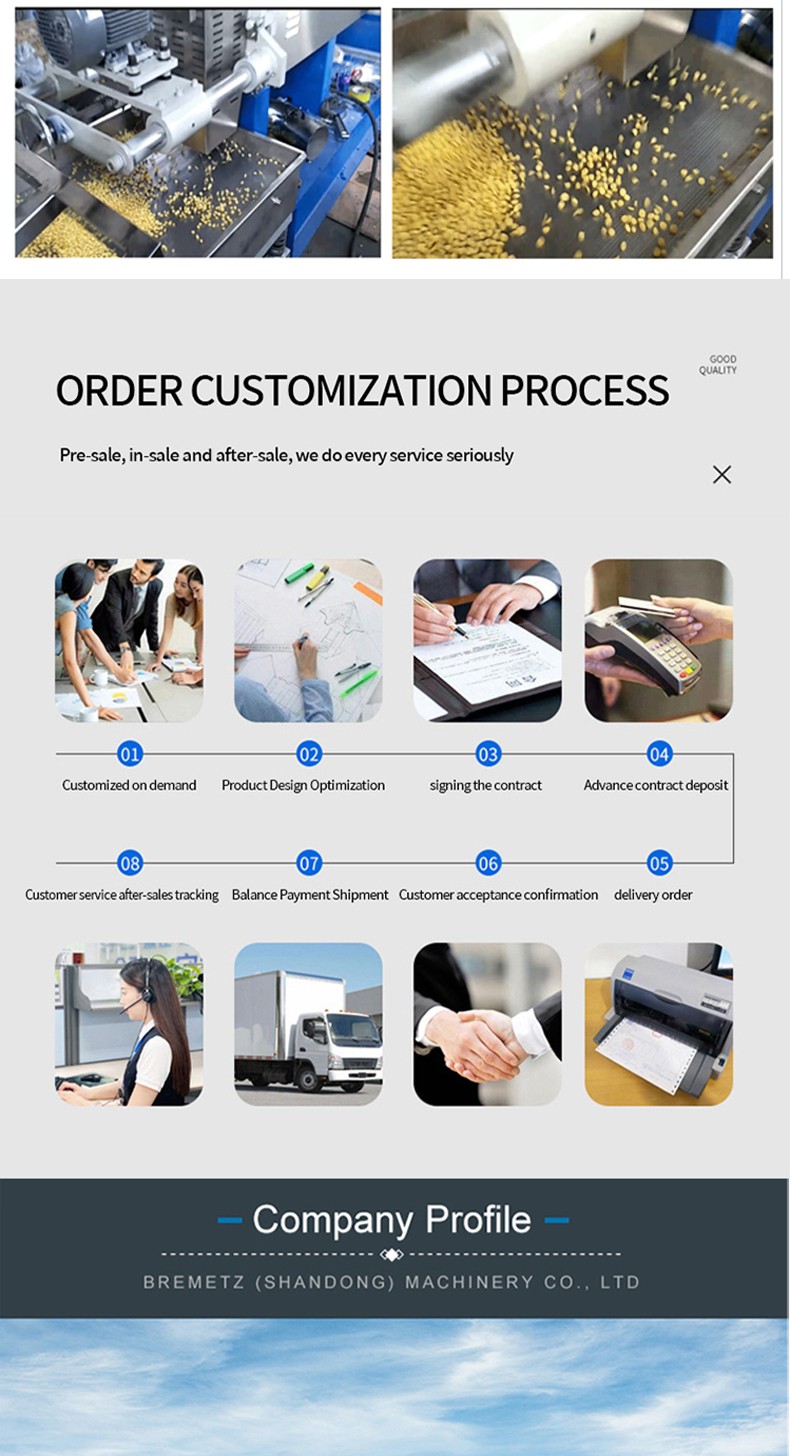

Corn puffing production equipment is a processing equipment for food, feed and some industrial products. The equipment is usually composed of control system, feeding system, drive system, extrusion system, temperature control system and rotary cutting system. Our company produces The casing, feeder and other parts of the twin-screw extrusion extruder are usually made of 304 stainless steel, and the screw, barrel, rotary cutting blade and other parts are made of high hardness alloy steel.

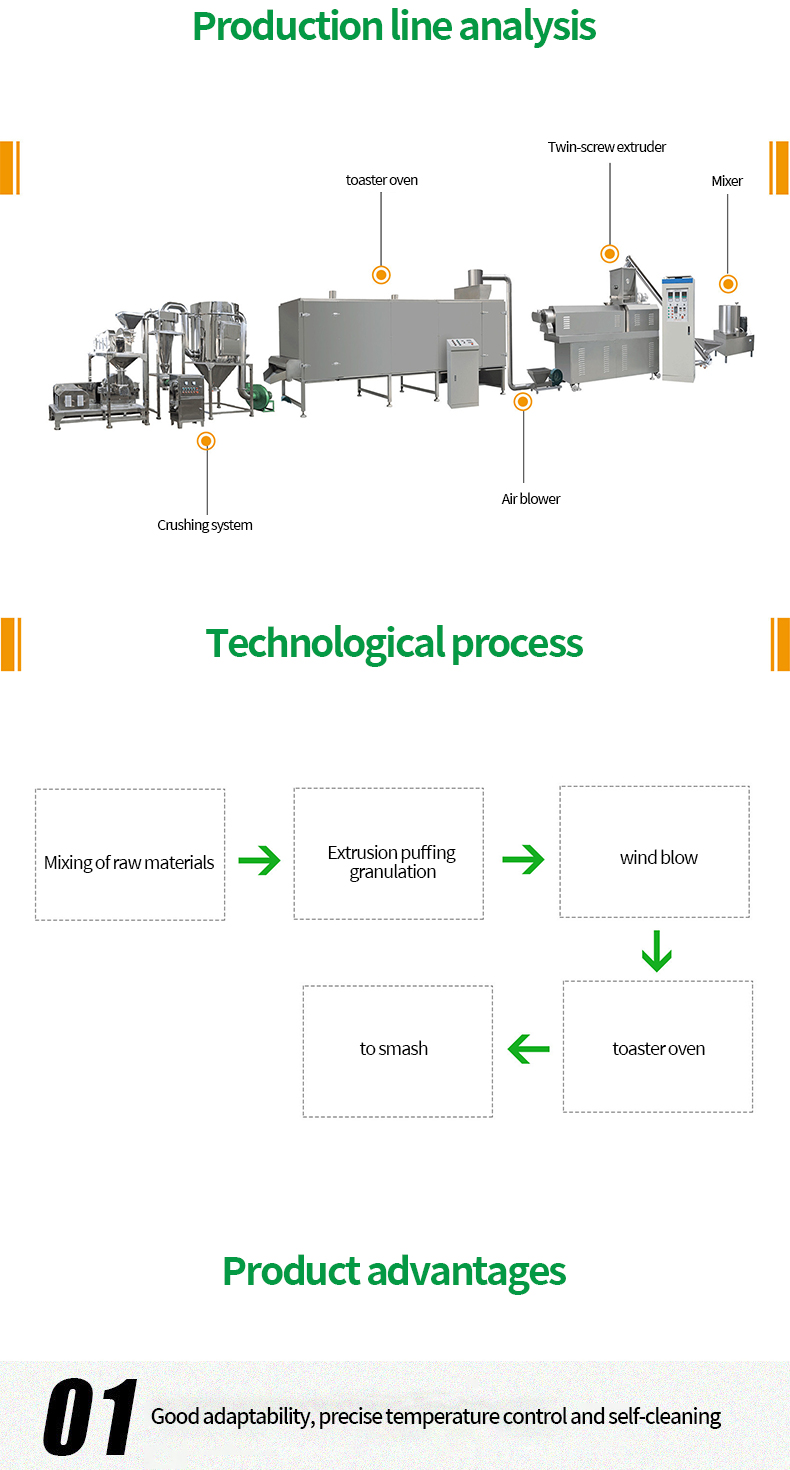

Product advantages:Good adaptability, precise temperature control and self-cleaning;roducts Wide range of raw materials, diverse production products; Frequency conversion speed regulation, high degree of automation;Stable operation and Ilong use time.

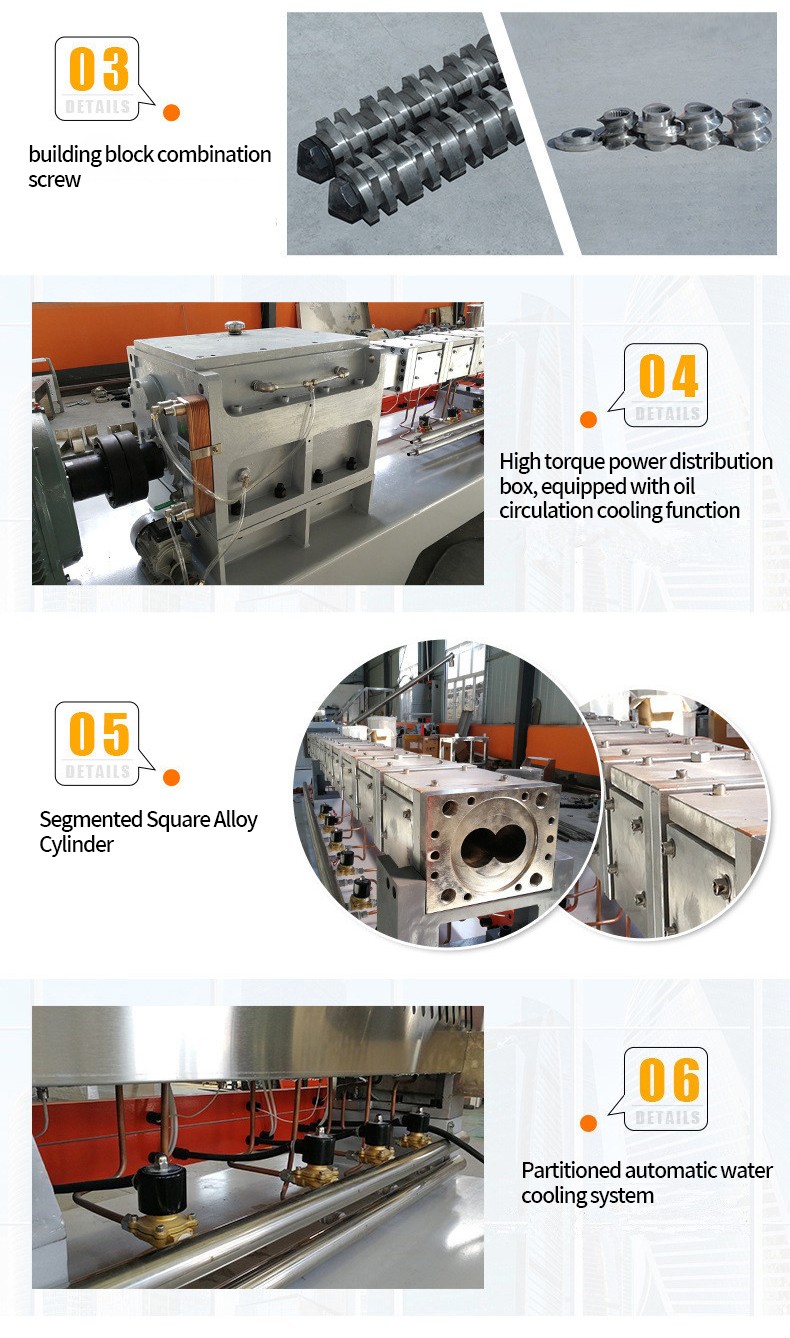

Details decide the quality:Frequency conversion direct connection type rotary cutting systeml;Anti-rust mold with high strength;building block combination screw,High torque power distribution box, equipped with oil circulation cooling function;Segmented Square Alloy Cylinder,Partitioned automatic water cooling system,Double shaft detachable frequency conversion feeder.

The use of advanced mechanical structure and power system ensures that the equipment can operate continuously and stably for a long time. During the entire puffing process, production will not be frequently interrupted due to equipment failure or unstable performance, thereby improving the overall production efficiency and stability of product quality.

Equipped with advanced control systems, operators can accurately set and adjust key parameters in the puffing process, such as temperature, pressure, material flow, etc. This precise control capability ensures stable puffing effects under different raw materials and product requirements.

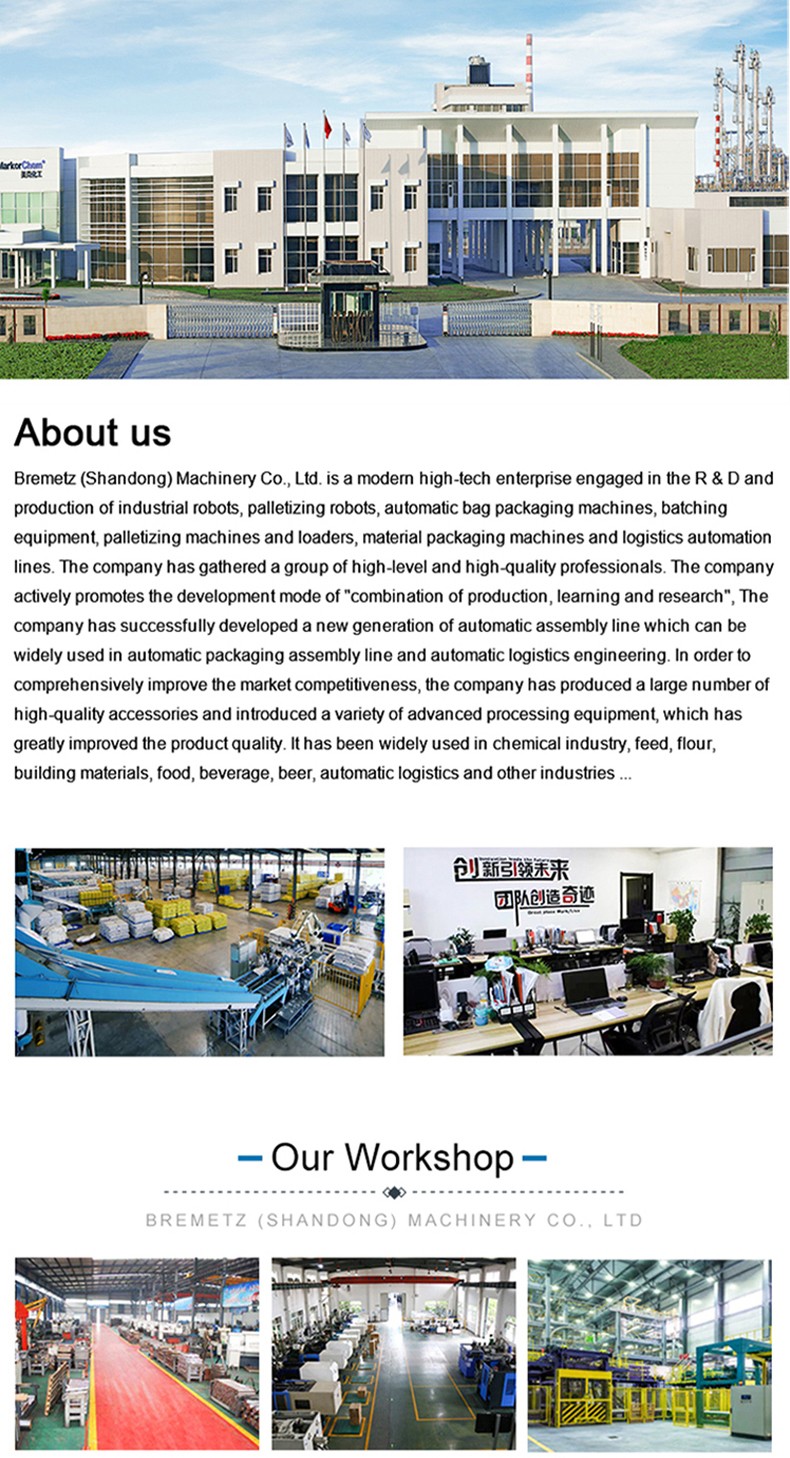

We provide users with reliable quality assurance, and the warranty period for the main body of the equipment is 1 year. During the warranty period, we will provide free equipment repair and replacement of damaged parts (except for damage caused by improper operation by the user). At the same time, we have a professional after-sales service team to provide users with technical support, operation training and equipment maintenance guidance at any time to ensure that users have no worries when using corn puffing production equipment.