Hopper lifting machine

1. It can lift materials to the required height in a short time, greatly improving the material conveying efficiency, especially suitable for production processes that require fast and continuous material conveying.

2. It has a large conveying capacity and can lift more materials at a time. Its conveying volume can range from more than ten cubic meters per hour to hundreds of cubic meters according to different models and specifications.

3. It can achieve a higher lifting height. The common bucket elevator can reach a lifting height of tens of meters, and the specially designed one can even exceed 100 meters.

4. Its overall structure has been carefully designed, and the connection between each component is firm and reliable, which can withstand the weight of the material and the pulling force during operation.

5. It can smoothly transmit power to the lifting components, so that the bucket maintains a uniform speed during operation, reducing material spillage and equipment vibration caused by speed fluctuations.

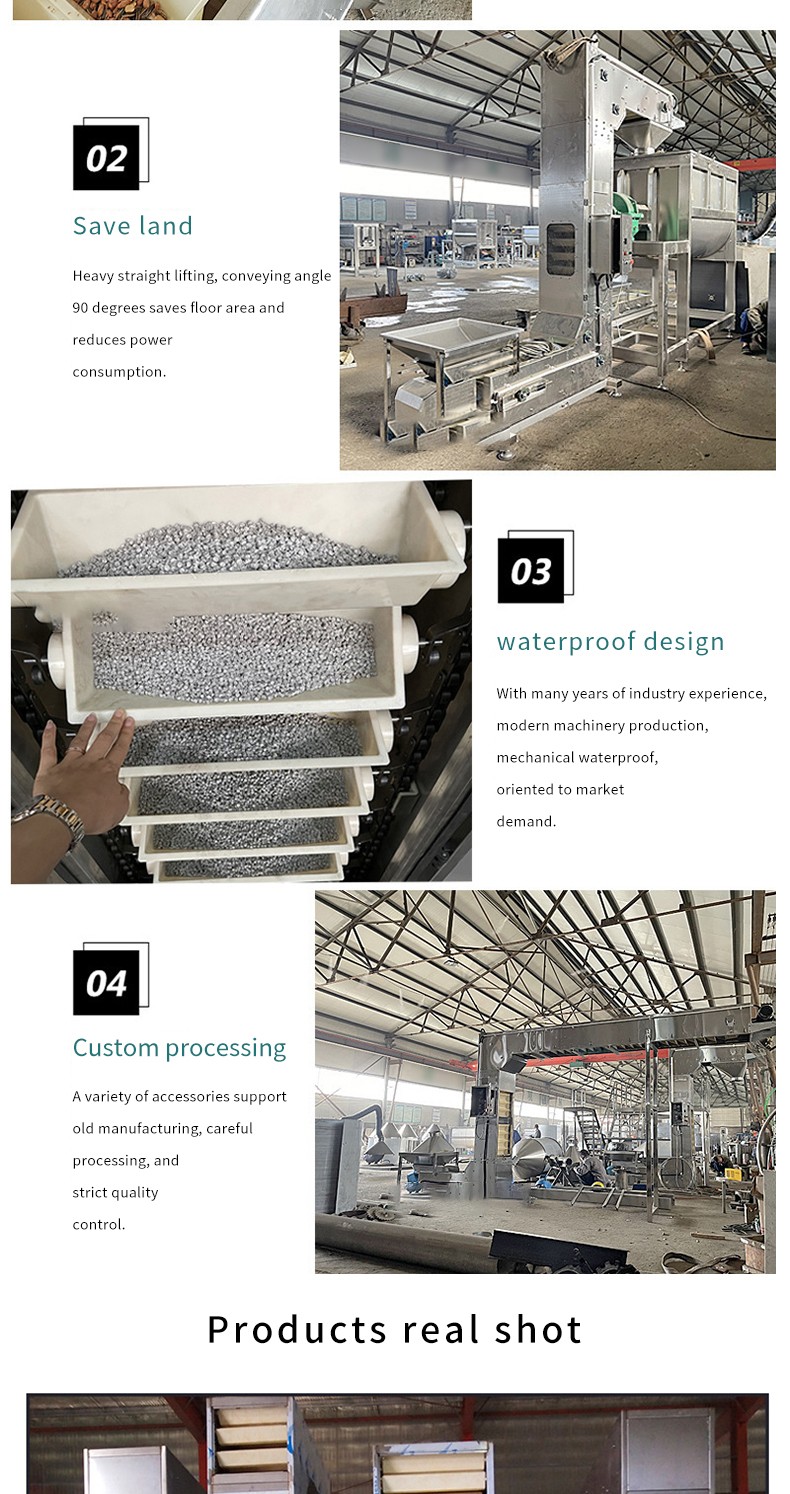

The hopper elevator is mainly composed of a drive device, a traction member, a hopper, a casing, a tensioning device, a feeding device, a discharge device, and a control system. Its overall design concept revolves around the efficient, stable, and safe vertical or inclined lifting of materials to meet the material transportation needs in different industrial production scenarios.

The integrated advanced frequency converter can realize stepless speed regulation of the hopper lifting speed. The operator can flexibly set the lifting speed within a wide speed range through the human-machine interface of the control system to adapt to the characteristics of different materials and production process requirements.

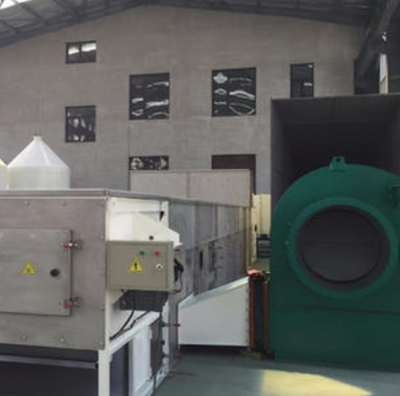

It adopts a combination of high-performance motors and reducers. The motor types include three-phase asynchronous motors, DC brushless motors, etc. It has a high power factor and efficiency and can provide stable and strong power according to different lifting tasks.

Equipped with complete motor protection devices, such as overload protection, overheat protection, short circuit protection, etc. When the motor is overloaded, overheated or short-circuited, the protection device can act quickly to cut off the power supply to the motor to prevent motor damage and ensure the safe operation of the equipment.

Traction components such as chains are generally made of high-strength alloy steel, which has good tensile strength, wear resistance and fatigue life. The pitch of the chain is reasonably designed according to the size of the hopper and the lifting load to ensure sufficient strength and stability during the power transmission process.

The shape and size of the hopper are customized according to the nature of the conveyed material and the process requirements. For powdered materials, the hopper is generally shallow with a large opening area to facilitate the feeding and unloading of materials, and the inner wall of the hopper is smooth to reduce material residue and blockage.