hopper elevator

1. High lifting speed: The bucket elevator can achieve a faster lifting speed and can quickly transport materials from low to high. This feature makes it perform well in large-scale production or frequent material transfer scenarios, and can effectively shorten the material transportation time.

2. Continuous and stable operation: Its structural design and working principle ensure stability during long-term operation. The transmission system and support structure of the bucket elevator are carefully designed to withstand the continuous loading of materials and various stresses during operation.

3. Quantitative delivery: The bucket has a certain capacity, and can achieve relatively stable quantitative delivery every time the material is scooped. This quantitative delivery feature is crucial for production processes that require precise control of the amount of materials.

4. Vertical delivery accuracy: Since the bucket elevator transports materials in the vertical direction, its conveying path in the vertical direction is more direct and accurate than some inclined or horizontal conveying equipment.

5. Multiple material types: It can handle various types of materials, including granular, powdery, blocky, etc. Whether it is loose sand, coal, powdery materials with a certain viscosity, or large-sized block ore.

6. Different material characteristics: It also has good adaptability to different material characteristics, such as density, humidity, fluidity, etc.

The hopper elevator is a mechanical device used to lift materials vertically, and is widely used in many fields such as industrial production, warehousing logistics, and construction. It achieves efficient transportation of materials from low to high places through a series of hoppers that circulate along a vertical path, effectively solving the problem of material transfer at different heights and providing a strong guarantee for the continuity and efficiency of the production process.

Factory direct supply.

Carefully selected material.

Support customization.

quality assurance.

fast delivery.

Integrity management.

product name: Hopper Elevator

product material: stainless steel etc.

Manufacturer: Shandong

Product Specifications: Non-standard

Product advantages: Save manpower, improve work efficiency, good quality, complete specifications

Applications: Food production, pharmaceutical manufacturing, machinery industry, assembly line operations, etc.

The food materials are clean and hygienic, the surface is self-smooth, and the good anti-oxidation ability is not easy to rot.

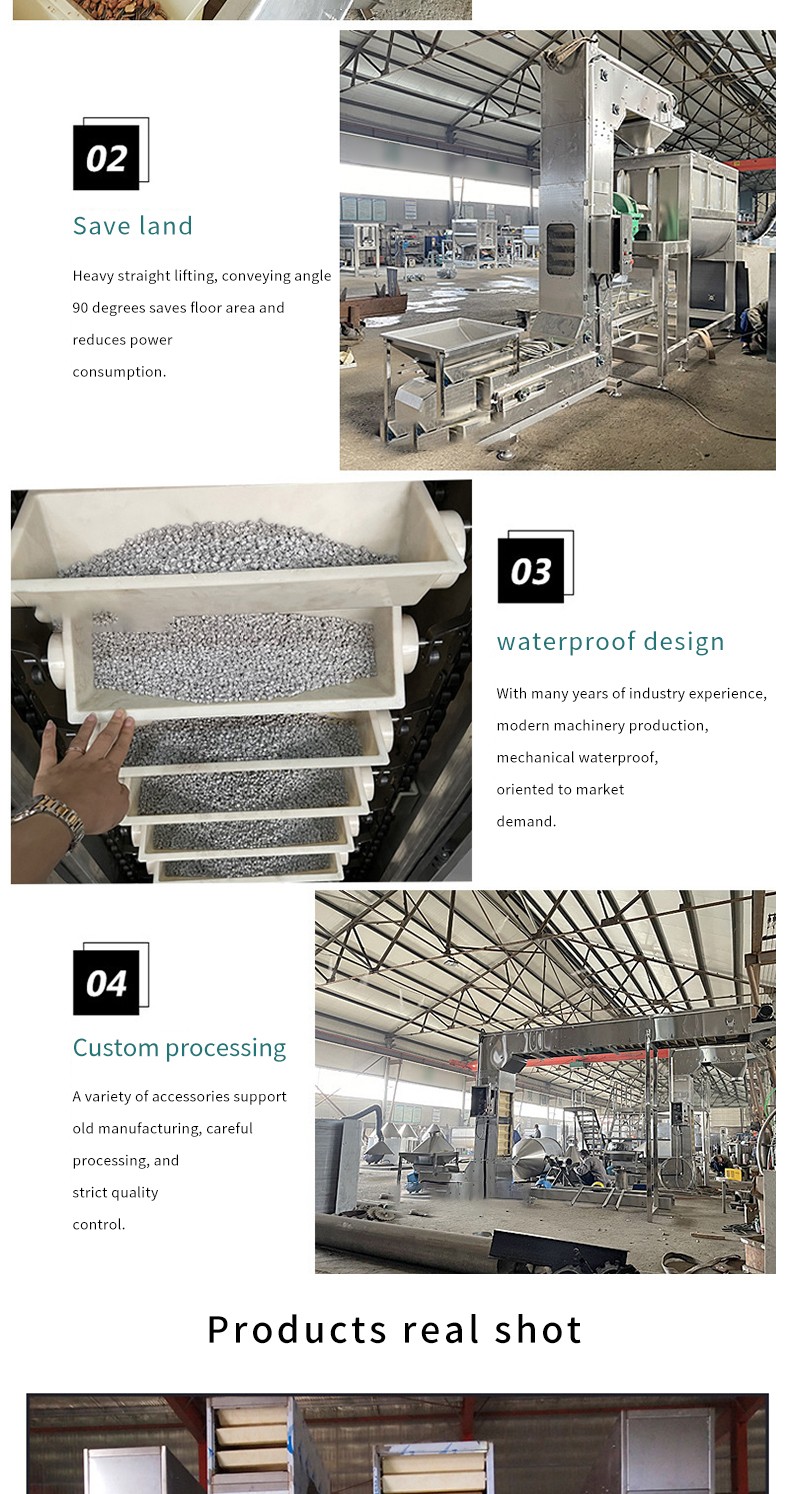

Save land,Heavy straight lifting, conveying angle 90 degrees saves floor area and reduces power consumption.

waterproof design,With many years of industry experience, modern machinery production, mechanical waterproof, oriented to market demand.

Custom processing,A variety of accessories support old manufacturing, careful processing, and strict quality control.

The hopper elevator can quickly and stably lift materials vertically to a higher position. Its lifting speed can be adjusted within a certain range according to actual needs to meet the requirements of different production scales and material flow rates. In large-scale material transfer scenarios, such as ore lifting in large mines, grain transportation in grain storage, etc., the efficient transportation capability of the hopper elevator can significantly improve production efficiency and reduce material transportation time.

Since the hopper has a certain capacity and the running speed of the hopper elevator is relatively stable, it is possible to achieve more accurate control of the material conveying amount. By adjusting the size and number of hoppers and the operating frequency of the elevator, the requirements for quantitative material conveying in different production processes can be met.

The company provides a professional installation team to install the hopper elevator to the location specified by the user. During the installation process, strictly follow the installation instructions and safety specifications of the equipment to ensure that all parts of the equipment are installed correctly and firmly, and the electrical connections are safe and reliable.