Chain bucket elevator

1. Adapt to a variety of materials: Whether it is powdery, granular, small block materials, or materials with certain abrasiveness, such as cement, coal, ore, sand and gravel, etc., it can be effectively transported, and it has strong adaptability to the types and characteristics of materials.

2. Diverse material states: For materials in different states such as wet, dry, and sticky, it has a good conveying effect.

3. Efficient conveying capacity: The bucket operates continuously under the drive of the chain, which can achieve rapid lifting of a large amount of materials. In addition, through reasonable design and optimization, the bucket of the elevator is tightly arranged, and more materials can be transported per unit time.

4. Stable and reliable operation: The chain is usually made of high-strength alloy steel material, with high tensile strength and wear resistance, and can withstand large tension and wear, ensuring the long-term stable operation of the equipment.

5. Strong anti-interference ability: For some occasions with harsh working environment, vibration, impact and other interference factors, the chain bucket elevator can maintain stable operation without being affected by external interference.

6. Adapt to environmental protection requirements: In some industries with high environmental protection requirements, such as chemical industry and grain processing, the good sealing performance of chain bucket elevator makes it an ideal material conveying equipment.

The power roller telescopic line is an advanced material conveying equipment that combines power drive and telescopic functions, and plays an important role in modern logistics, warehousing, manufacturing and other fields. This equipment can efficiently and flexibly convey various types of goods through the coordinated work of the telescopic structure and the power roller, effectively solving the problems of varying conveying lengths and complex conveying paths for goods in different working environments, and providing strong support for enterprises to improve production and logistics efficiency.

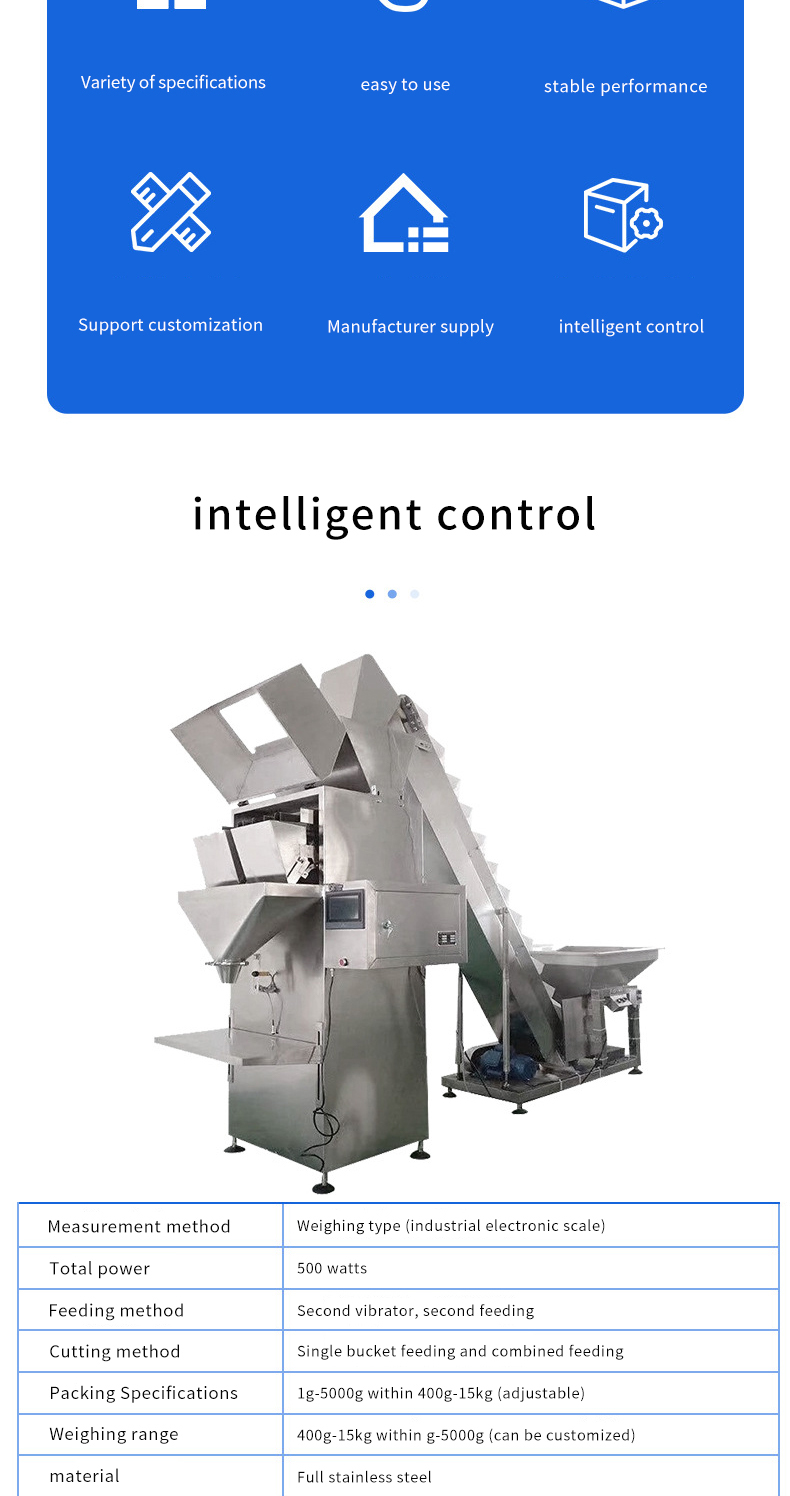

Measurement method:Weighing type (industrial electronic scale)

Total power:500 watts

Feeding method:Second vibrator, second feeding

Cutting method:Single bucket feeding and combined feeding

Packing Specifications:1g-5000g within 400g-15kg (adjustable)

Weighing range:400g-15kg within g-5000g (can be customized)

material:Full stainless steel

single bag error:±1g<single bag error s:3 (determine error according to material circulation)

packing speed:10-206-12 bags/min

Total Weight:200 kg

Overall volume:720*820*2200mm The distance between the working material connection port and the ground is 72cm

stepper motor gate,Equipped with a special stepping motor gate mechanism that is rare in the market.

Meticulous workmanship,Meticulous workmanship, excellence, use of high-quality stainlesssteel materials.

Stable electronic control system,Tried and tested stable electronic control system.

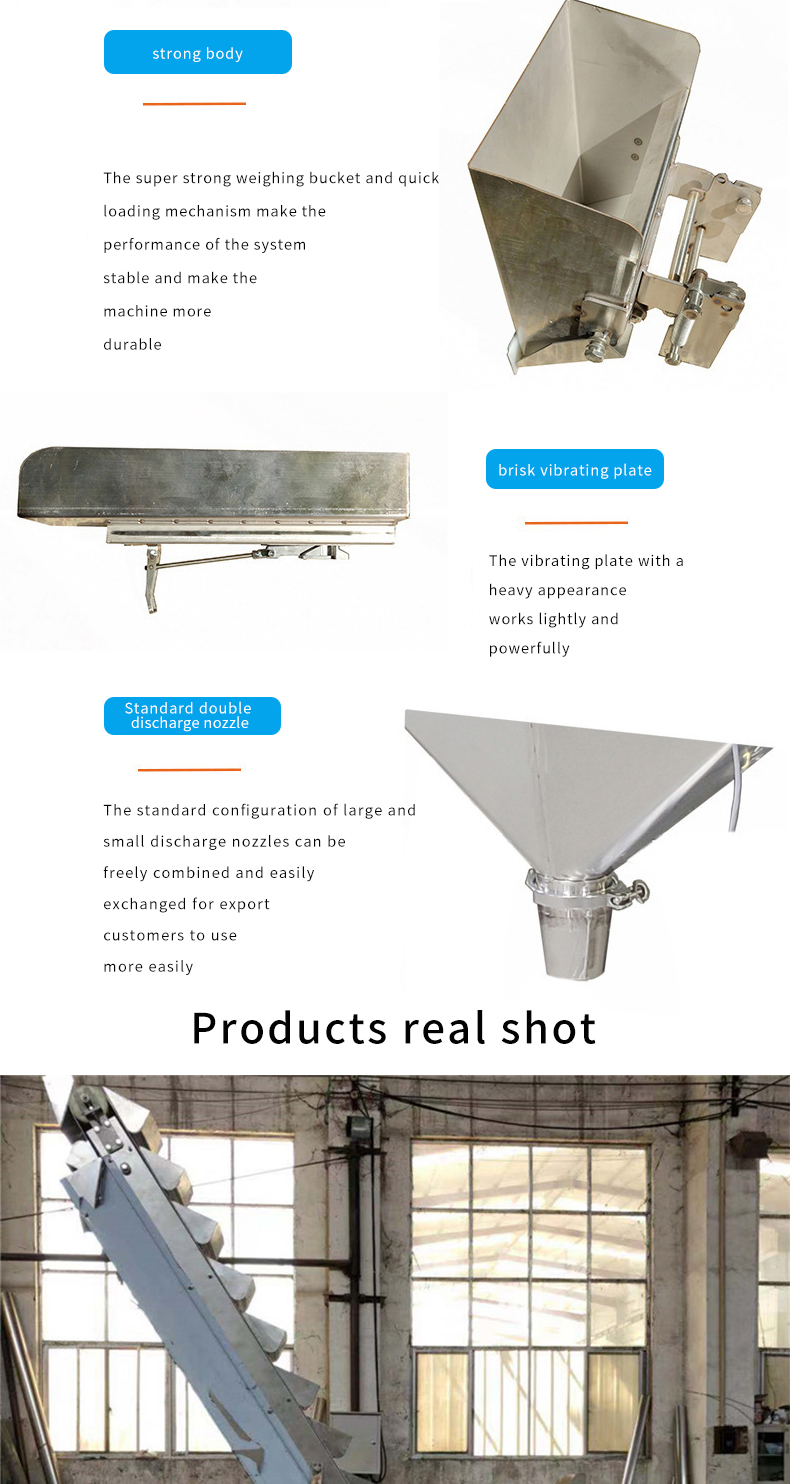

Strong body,The super strong weighing bucket and quick loading mechanism make the performance of the system stable and make the machine more durable.

Brisk vibrating plate,The vibrating plate with a heavy appearance works lightly and powerfully.

Standard double discharge nozzle,The standard configuration of large and small discharge nozzles can be freely combined and easily exchanged for export customers to use more easily.

The power-driven roller ensures fast and stable transportation of goods, improving logistics and production efficiency. The conveying speed can be adjusted according to actual needs to adapt to different operation processes and types of goods. Compared with traditional manual handling or non-powered conveying equipment, it greatly shortens the turnover time of goods and reduces labor costs and labor intensity.

The retractable feature allows the equipment to be retracted to a smaller size when not in use, taking up less space. This space advantage is particularly evident in places with limited space, such as small warehouses or workshops in the city center. The partially foldable power roller retractable line is more convenient for storage and transportation, further improving space utilization and equipment maneuverability.

The company provides a professional installation team to install the power roller telescopic line to the location specified by the user. During the installation process, strictly follow the installation instructions and safety specifications of the equipment to ensure that all parts of the equipment are installed correctly and firmly, and the electrical connections are safe and reliable.