Belt conveyor elevator

1. It has a high conveying capacity, and its belt width and running speed can be designed and adjusted according to actual needs, which can meet the continuous conveying and lifting requirements of large-scale materials.

2. The use of advanced drive technology and high-quality motors, reducers and other power equipment ensures the high-speed and stable operation of the belt during the lifting process.

3. By adjusting the material, surface texture, spacing and form of the belt, it can adapt to the physical properties of different materials, such as friction, viscosity, fluidity, etc.

4. It is designed with standardized interfaces and communication protocols, which can be easily seamlessly connected with upstream and downstream production equipment to achieve automated integration of the entire production process.

5. The main structural components are made of high-strength steel or aluminum alloy materials, with good rigidity and fatigue resistance, and can withstand large material weight and impact.

6. It can be designed into a linear, curved, inclined, vertical or multiple combinations of layouts according to different site conditions and production process requirements.

The belt conveyor hoist is mainly composed of a drive device, a conveyor belt, a tensioning device, a roller assembly, a frame, a feeding device, a discharge device and a control system. Its overall design concept focuses on achieving efficient, stable, safe and flexible vertical or inclined material conveying and lifting functions.

The high-performance motor and reducer combination includes three-phase asynchronous motor, brushless DC motor, etc. It has high power factor and efficiency and can provide stable and strong power according to different conveying tasks.

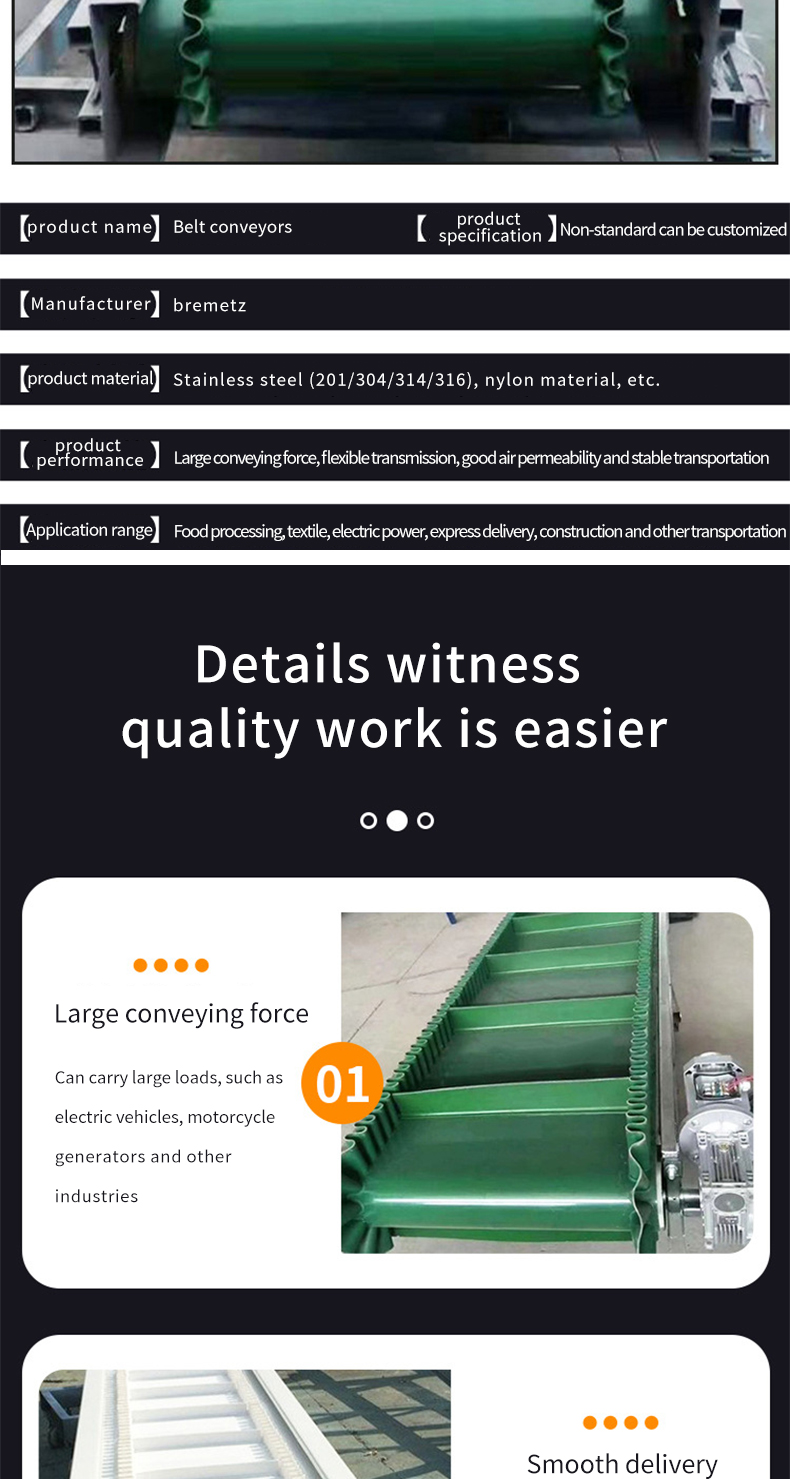

product name:Belt conveyors

product specification:Non-standard can be customized

Manufacturer:bremetz

product material:Stainless steel (201/304/314/316), nylon material, etc.

product performance:Large conveying force, flexible transmission, good air permeability and stable transportation.

Application range:Food processing, textile, electric power, express delivery, construction and other transportation.

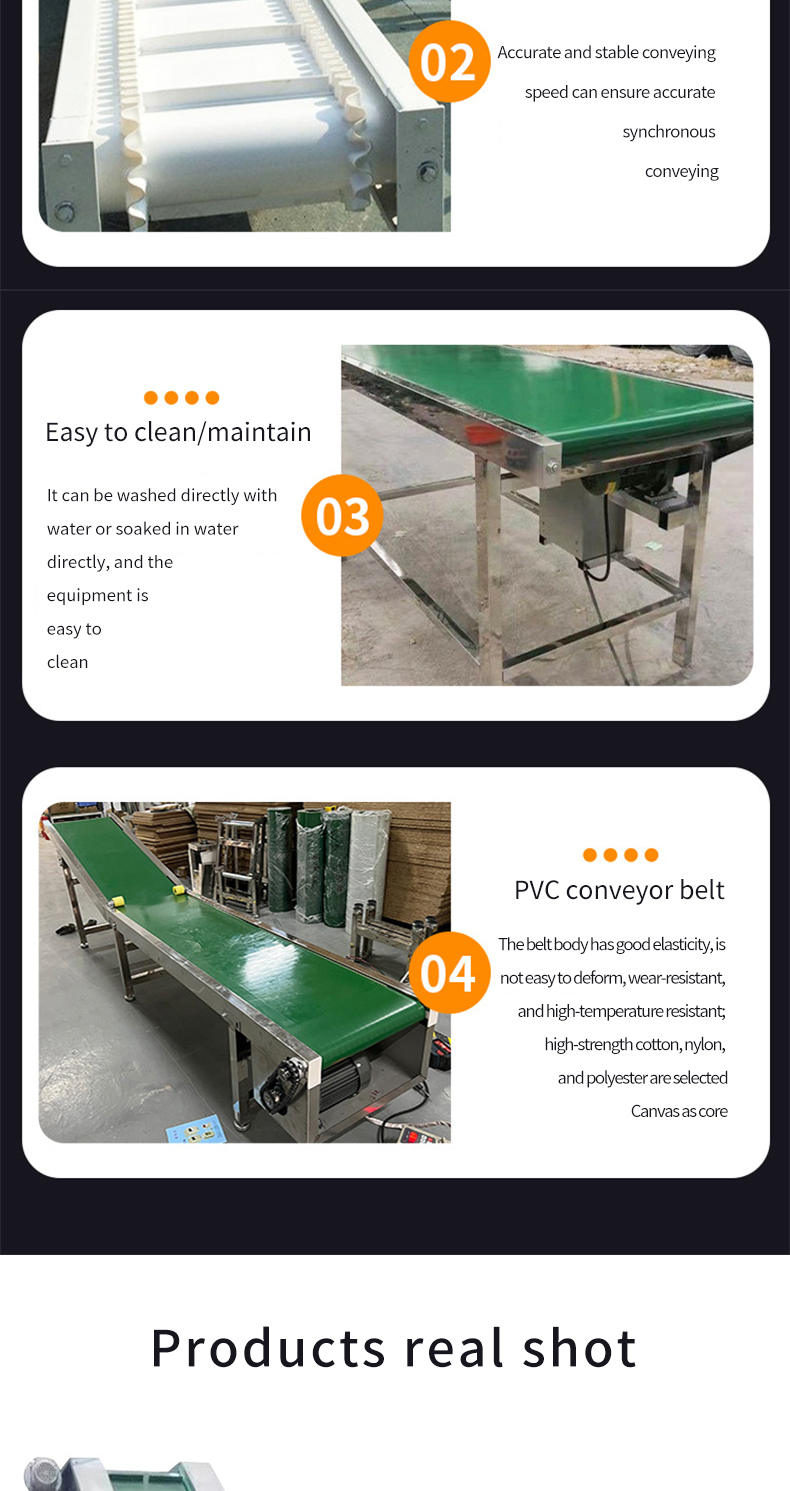

The material of the conveyor belt is carefully selected according to the nature of the conveyed material. For general materials such as coal, ore, grain, etc., wear-resistant rubber conveyor belts are often used. The surface has moderate friction, which can ensure that the material is stably attached during the lifting process and is not easy to slip.

The PLC-based control system combined with high-precision sensor technology realizes intelligent and precise control of the equipment. It can accurately control parameters such as material conveying speed, lifting height, and unloading position with minimal error.

The perfect safety system covers emergency stop, protective devices, fault detection and alarm, safety interlock and authority management, etc. It effectively prevents casualties and equipment damage accidents.

It can be designed into various layout forms according to different site conditions and production process requirements, such as straight line, curved, inclined, vertical or various combinations.

Whether it is a block, granular or powdery material, the belt conveyor elevator can handle it effectively. By adjusting the material of the belt, the surface texture, the spacing and form of the rollers, etc., it can adapt to the physical characteristics of different materials.