Stacking Machine

1. With high-speed and stable operation performance, it can complete the stacking task of a large number of goods in a short time.

2. Equipped with an advanced positioning system, it can accurately control the stacking position of the goods with minimal error, ensuring that the goods are stacked neatly and firmly.

3. It can realize fully automated operation from cargo grabbing, handling to stacking, without a lot of manual intervention, reducing labor costs.

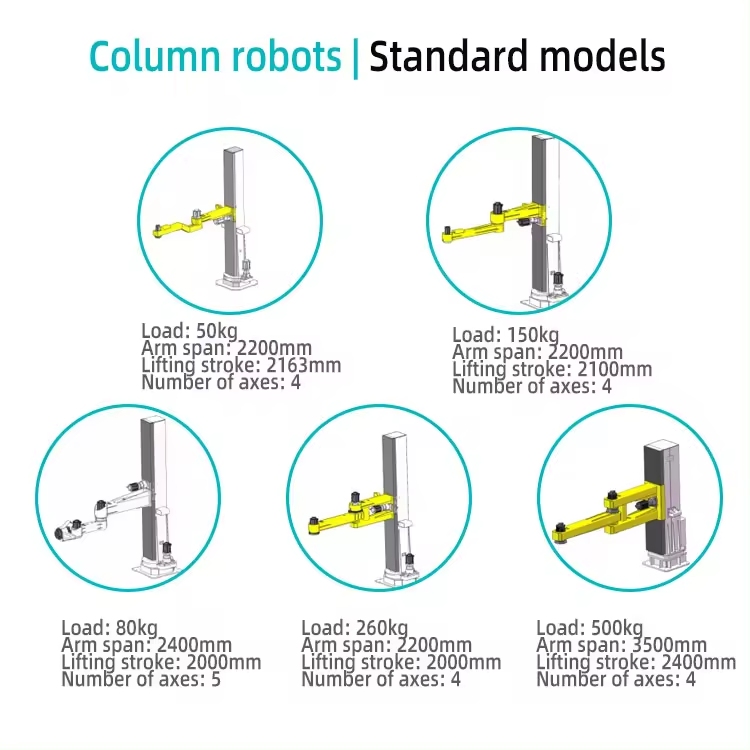

4. Through programming and parameter adjustment, it can adapt to the stacking needs of goods of different shapes, sizes and weights.

5. It is designed with multiple safety protection devices, including collision detection sensors, emergency stop buttons, safety light curtains, etc.

This Stacking Machine is a highly automated, precise and efficient logistics and warehousing equipment designed to solve the stacking problems of various goods. It is widely used in warehouses and production workshops in many industries such as manufacturing, food and beverage, e-commerce logistics, and chemical industry.

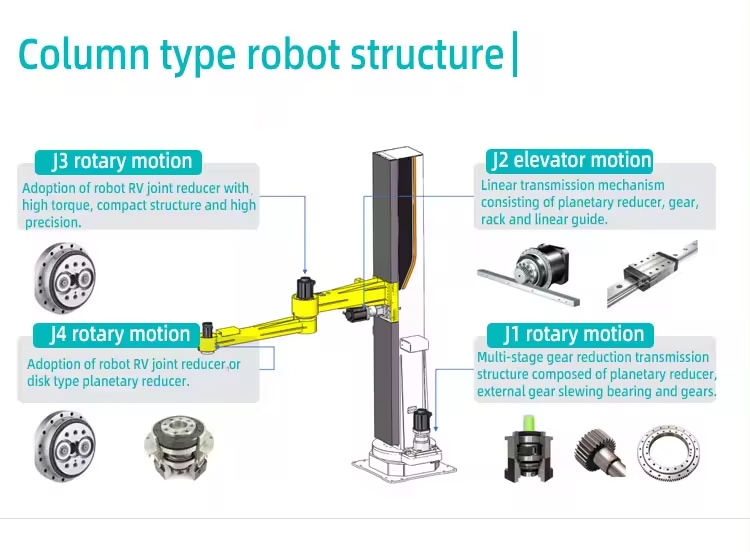

Using high-performance motors and optimized transmission systems, the stacker has fast operating speeds in both horizontal and vertical directions, greatly shortening the time cycle for stacking goods, significantly improving warehousing operation efficiency, and meeting the high-intensity production of enterprises. Logistics needs.

The entire process from grabbing, transporting to stacking of goods is highly automated, without the need for manual intervention, reducing labor costs and labor intensity, while also lowering the risk of human operational errors.

By replacing different types of forks and clamps, the stacker can adapt to the stacking needs of goods of various shapes, sizes and weights. The design of the stacker fully considers the compatibility with different types of shelves and can operate in various common shelf systems.

To ensure the safety of operators and equipment, the stacker is equipped with a complete safety protection system, including but not limited to laser anti-collision sensors, safety light curtains, mechanical anti-collision buffers, emergency stop buttons, etc.

Equipped with an intuitive and convenient human-machine interactive touch screen, the operator can easily start, stop, set parameters, monitor tasks, query faults and other operations on the stacker through this interface.

The stacker crane is designed with full consideration of the convenience of maintenance, adopting a modular structure design and a layout of parts that are easy to disassemble.