Pallet depalletizing machine

1. It can complete the depalletizing task of a large number of pallets in a short time, and its depalletizing speed is usually several times or even dozens of times faster than manual operation.

2. It can work continuously for a long time, maintain stable depalletizing performance, and ensure the continuity of production or logistics.

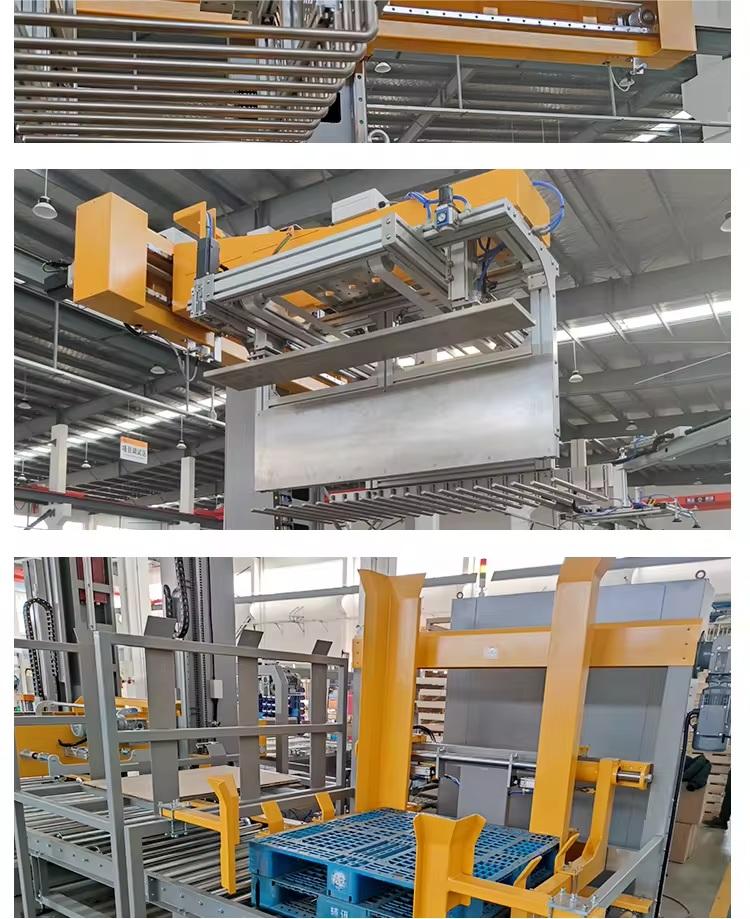

3. Through advanced sensors and control systems, it can accurately locate and grab the goods on the pallet.

4. During the depalletizing process, the goods can be unloaded from the pallet in an orderly manner according to the preset procedures and requirements.

5. It adopts a sturdy and durable structural design and high-quality components, with high stability and reliability, reducing safety hazards caused by equipment failure.

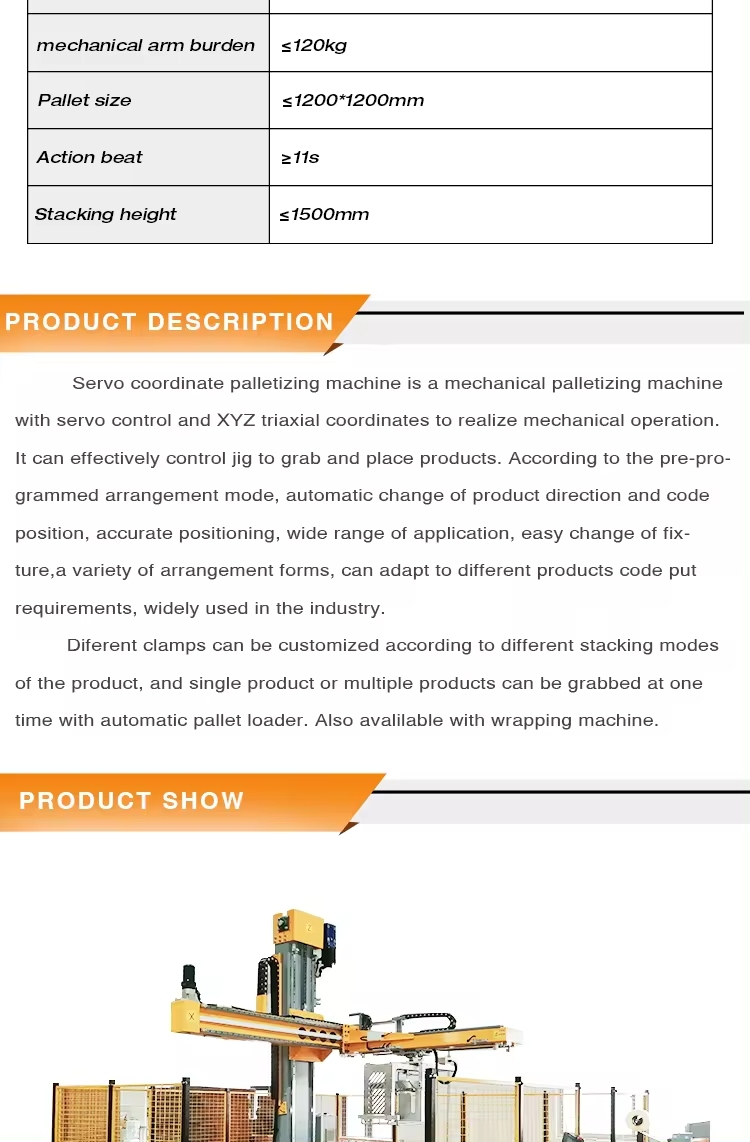

This Pallet depalletizing machine is an efficient, intelligent and automated equipment specially designed for the modern logistics and warehousing industries. It aims to solve the problems of low efficiency, high labor cost, poor operation accuracy and high safety risks in the process of depalletizing pallets.

Model:SMD12

Power supply:3Phase, AC220V/380V,50/60HZ, 7KW

Air pressure:450NL/min

Machine Size:L4500*W4300*H3500mm

mechanical arm burden:≤120kg

Pallet size:≤1200*1200mm

Action beat:≥11s

Stacking height:≤1500mm

With high-performance motors and optimized transmission systems, the pallet depalletizer has fast response speed and operation efficiency in every link such as conveying, lifting and grabbing.

From the feeding of pallets, the grabbing and depalletizing of goods to the output of goods, the entire process is highly automated and does not require manual intervention, greatly reducing labor costs and labor intensity.

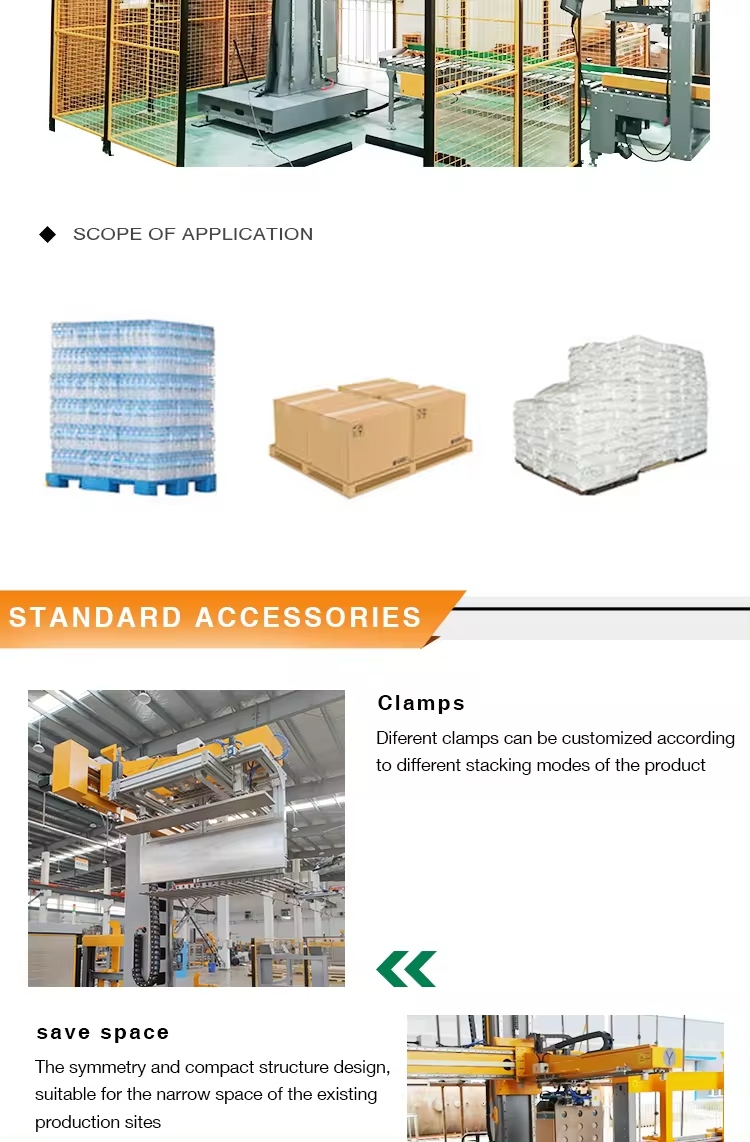

By replacing different types of gripping devices and adjusting equipment parameters, the pallet depalletizer can adapt to the depalletizing needs of goods in various shapes, sizes, weights and packaging forms.

The control system of the pallet depalletizer has powerful algorithms and adaptive capabilities. It can perform intelligent analysis and processing according to the characteristics of different pallet types and cargo arrangement, and automatically adjust the grabbing strategy and depalletizing sequence.

Equipped with an intuitive and convenient human-machine interactive touch screen, the operator can easily start, stop, set parameters, monitor tasks, query faults and other operations of the pallet depalletizer through this interface.