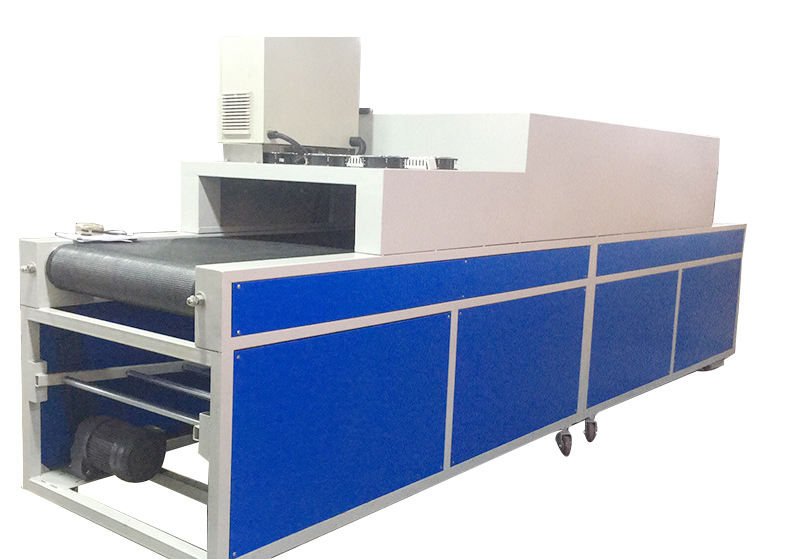

Fully automatic tunnel drying line

1. Uniform heating: The baked product is heated inside and outside at the same time, and the temperature difference between the inside and outside is small, which can effectively avoid deformation, discoloration and other problems of the product due to uneven heating.

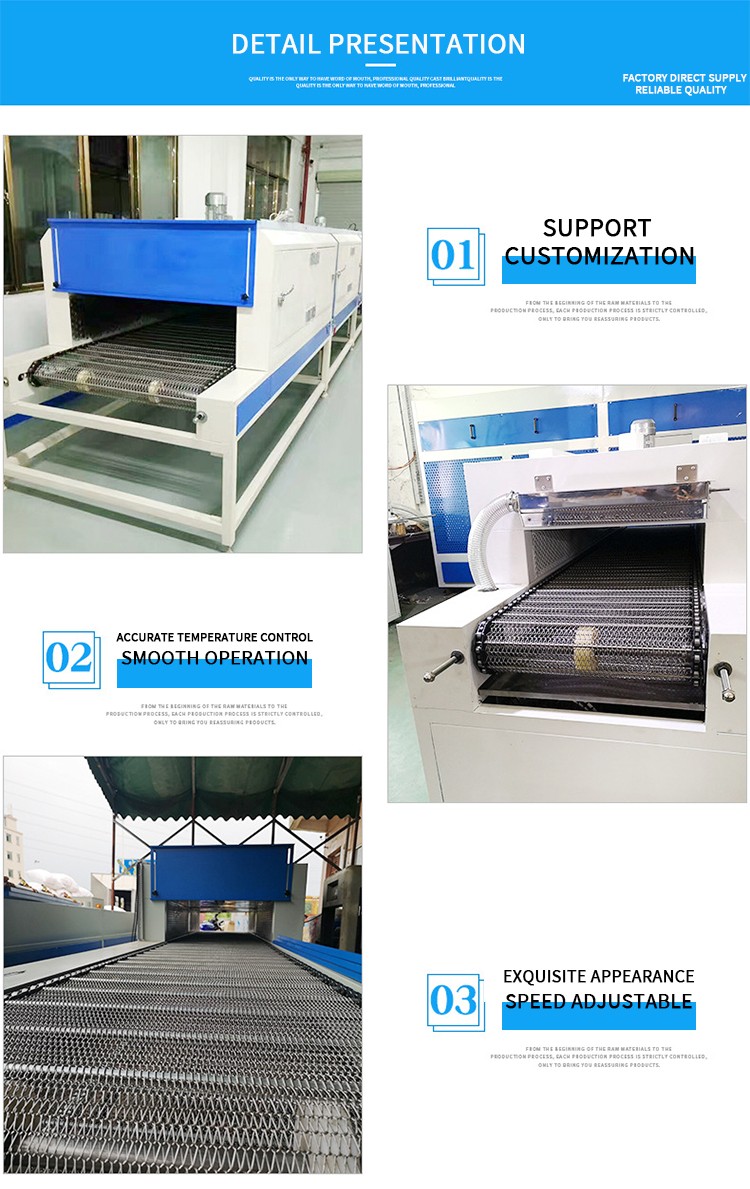

2. Accurate temperature control: The stepless constant temperature control system is adopted, and the segmented temperature control can be used according to the drying requirements of different products.

3. Fast speed: The baking time can be shortened by 1/6-1/4, which can greatly shorten the production cycle, improve production efficiency, and meet the needs of mass production.

4. Continuous drying: It can realize uninterrupted transportation and drying of materials without frequent loading and unloading of materials and start and stop operations of equipment.

5. Large energy transmission per unit area: Due to its special structural design and heating method, the energy transmission per unit area is large, so the equipment volume is relatively small.

6. Online production: It can be used in line with the production line to realize the automatic connection and synchronous control of the production process, and effectively control the number of work-in-progress.

The fully automatic tunnel drying line adopts an integrated and modular design structure, with a compact and reasonable overall layout and efficient and smooth coordinated operation of all parts. Its main frame is constructed of high-strength metal materials, with excellent stability and durability, and can withstand long-term and high-intensity workloads.

The segmented temperature control of the heating system, the good circulation of the ventilation system and the precise adjustment of the control system ensure that the materials receive appropriate temperature, humidity and ventilation conditions at different stages, making the drying process more scientific and reasonable, and significantly improving the drying efficiency. drying efficiency and product quality.

It can meet the drying needs of materials of various types, shapes, sizes and properties. Through simple parameter adjustment or process optimization, the drying conversion of different products can be realized. Whether it is solid, liquid, powdery materials, or large blocks, small particles, flakes, filaments and other materials of different shapes, they can all be well processed on this equipment.

Name: Tunnel drying line

Brand: Bremetz

Section control: 2 meters a section of independent temperature control Model: ZDNM

Use: drying, curing

Speed: Frequency control

Temperature control mode: solid state, SCR, PLC

Furnace length: 2~50 meters or design

Furnace body width: 0.4~2.5 meters or design

Conveyor belt: chain plate conveyor, stainless steel forget belt, Teflon mesh belt, PVC mesh belt and so on

Heating system: far red line, carbon fiber, stainless steel, heating plate, gas and other options

The control system based on PLC and touch screen human-machine interface has intelligent parameter setting, fault diagnosis, data storage and statistical analysis functions. Operators can easily set and adjust equipment parameters through the intuitive and convenient operation interface, and various information during the operation of the equipment is clear at a glance.

Energy conservation and environmental protection requirements are fully considered during the design and manufacturing process, and energy-saving heating elements, optimized ventilation systems and intelligent control technologies are used to reduce the energy consumption of equipment.

Scope of application and application scenarios:

Food industry: widely used in food drying, such as fruit drying, vegetable dehydration, nut baking, meat drying, etc.

Electronic industry: used for drying and curing of electronic components, circuit boards, etc. In the production process of electronic components, such as chip packaging, capacitor and resistor manufacturing, it is necessary to remove moisture and solvent residues to ensure product performance and reliability

Pharmaceutical industry: The fully automatic tunnel drying line can dry drugs in strict accordance with the requirements of pharmaceutical production quality management specifications.

Chemical industry: suitable for drying chemical raw materials, coatings, pigments, plastic particles, etc.

We have established a complete after-sales service quick response mechanism and a dedicated after-sales service hotline. Customers can call the hotline at any time when they encounter equipment problems.