Roller grinding machine

Roller grinding machines have the advantages of high grinding efficiency, low energy consumption, low noise, and easy operation. They are widely used in the grinding and processing of ores, limestone, gypsum, coal, and chemical raw materials. When selecting a roller grinder, it is necessary to select the appropriate model and specification based on the nature of the raw material and grinding requirements to ensure production efficiency and product quality.

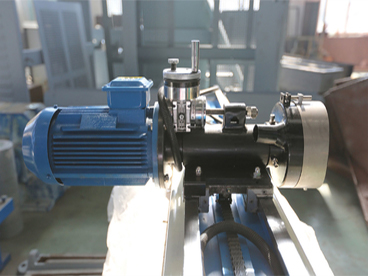

Roller grinding machines usually consist of a frame, a transmission system, a grinding roller, a roller shell, a feeding device and a discharging device. During its working process, the raw materials enter the grinding area between the grinding rollers through the feeding device. Through the high-speed rotation and relative movement of the grinding rollers, the raw materials are continuously squeezed and ground, and finally form the required particle size and pass through the discharging device. discharge.

Roller grinding machine product parameters:

Roller grinder The roll grinder is docked on the base of the rolling mill, which eliminates the need to disassemble the rolls. It is a special equipment for online grinding.

The roller grinding machine is equipped with a hydraulic lift truck, which is easy and fast to operate.

The cup-shaped grinding wheel used in the roller grinder is small in size, light in weight, reasonable in structure and easy to operate.

Since the roller grinding machine adopts vertical grinding, the pattern direction of the ground roller surface is conducive to the feeding of the roller.

Roller grinding machine weight: 320kg

Roller grinding machine size: 1500×600×550

Bring a vacuum cleaner.

Working principle:

Roller grinder is a kind of equipment used to crush or grind raw materials. It is widely used in chemical industry, metallurgy, building materials, mining and other industries. Its main working principle is to squeeze and grind the raw materials through two grinding rollers rotating in the same direction, so that the raw materials are gradually crushed or ground into the required particle size.