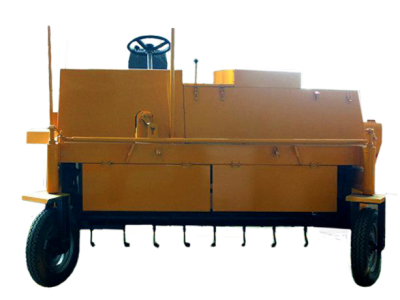

High efficiency roller conveyor

1. Fast conveying speed: It can achieve high conveying speed and can quickly move large quantities of goods from one location to another.

2. Large throughput: Its wide conveying surface and efficient roller operation can continuously handle large quantities of goods.

3. Suitable for transporting a variety of goods: It can transport all kinds of items, including boxes, pallets, barrels and irregularly shaped objects.

4. Adapt to a variety of environments: It can operate well in different working environments such as normal temperature, high temperature, humidity, and dust.

5. Energy-saving operation: Roller conveyors usually have a relatively simple structure and low energy consumption.

6. Smooth conveying: The rollers rotate smoothly to ensure smooth transportation of goods without obvious vibration or bumps. This helps to protect the integrity of the goods and reduce the risk of damage during transportation.

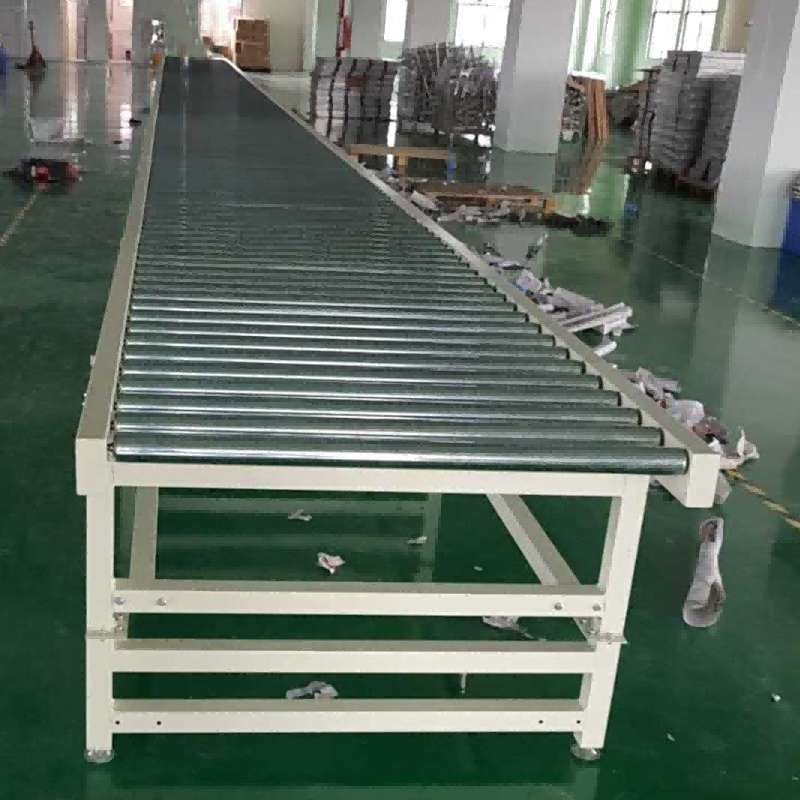

High-efficiency roller conveyors mainly rely on the rotation of the roller to transport goods. The power device drives the roller to rotate through the transmission system, and the goods placed on the roller move forward under the action of friction as the roller rotates. It runs smoothly and can meet the transportation needs of goods of different weights and shapes.

The rollers are made of high-quality steel or high-strength engineering plastics, which have good wear resistance and load-bearing capacity. The surface of the roller can be processed according to the characteristics of the goods. For example, the smooth surface is suitable for general goods, while the surface with texture or rubber coating can increase the friction between the goods and is used to transport smoother or heavier goods.

The frame is generally welded from carbon steel or stainless steel, and has sufficient strength and rigidity to withstand the weight of the entire conveyor and the various forces generated by the goods during transportation. The design of the frame focuses on the balance between lightness and stability, which not only ensures the stability of the equipment during operation, but also facilitates installation and movement.

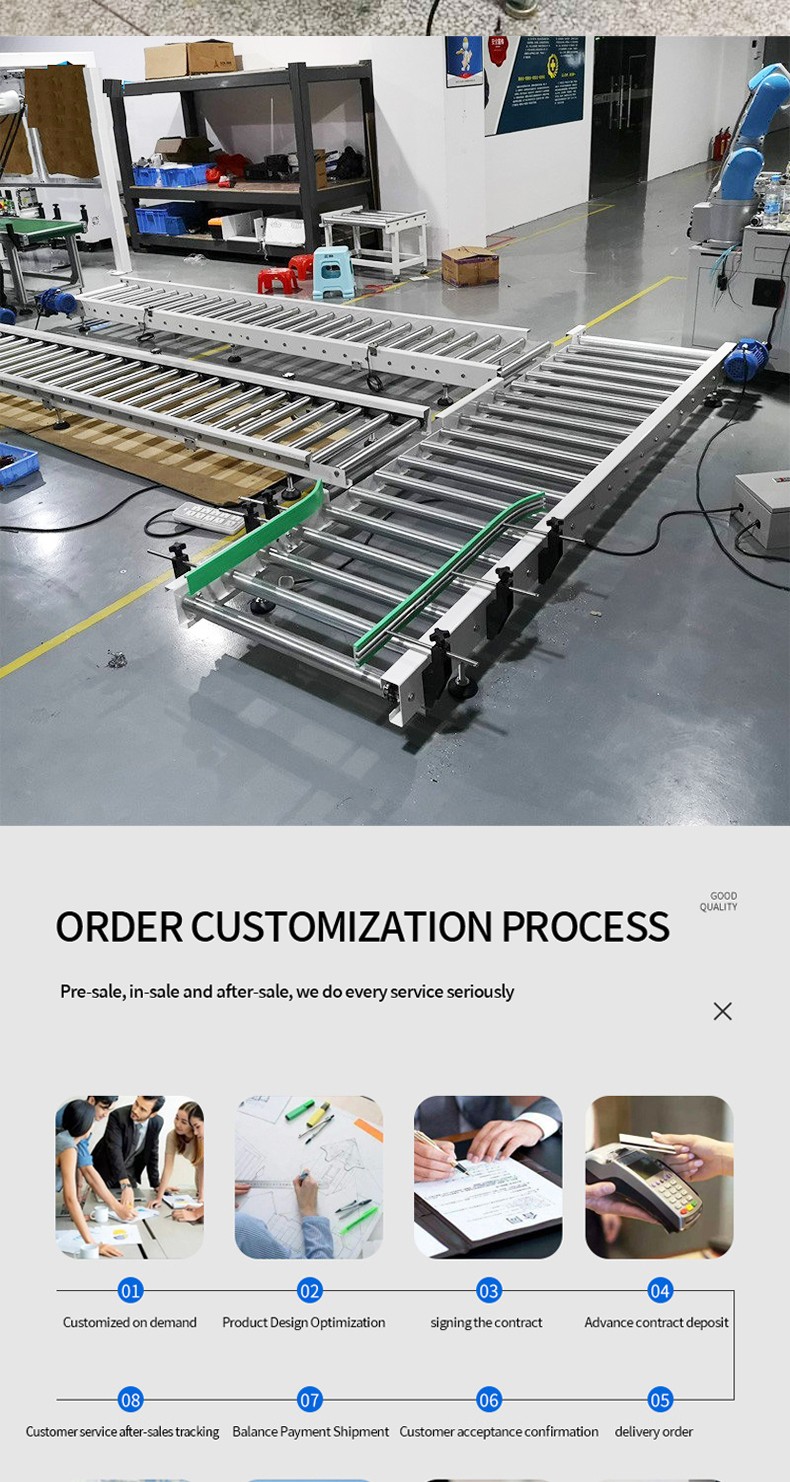

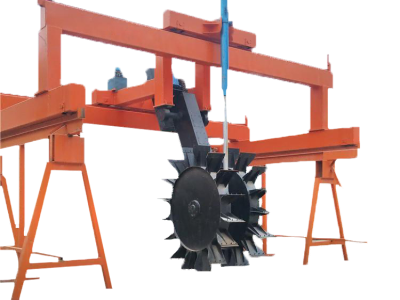

Different transmission methods can be selected according to factors such as conveying distance, load size and working environment. Chain transmission has the characteristics of high transmission efficiency and strong carrying capacity. It is suitable for long-distance and high-power transmission needs, but it requires regular lubrication and maintenance.

It has a high conveying speed, which can generally reach tens of meters per minute or even higher, greatly improving the transportation efficiency of goods. On the automated production line, it can quickly transfer raw materials, semi-finished products or finished products between various workstations, reducing production cycles and improving production efficiency.

Due to its relatively simple structure, high transmission efficiency and low energy consumption during operation, it can save a lot of energy consumption and reduce the operating costs of enterprises compared with some complex conveying equipment. At the same time, low energy consumption also means reducing the negative impact on the environment, which is in line with the development concept of modern green environmental protection.

Customized design and adjustment can be made according to different cargo shapes, sizes and weights. By replacing rollers of different specifications, adjusting roller spacing or changing the frame structure, it can meet the transportation needs of various types of cargo. Whether it is small electronic products or large mechanical equipment, they can be transported smoothly on the efficient roller conveyor.

The company provides a professional installation team to carry out on-site installation of high-efficiency roller conveyors according to the customer's site layout and equipment requirements. The installation process strictly follows relevant standards and specifications to ensure that the equipment is firmly installed and runs smoothly.

A dedicated after-sales service hotline has been set up. Customers can call the after-sales service hotline at any time when they encounter equipment failures or problems during use. After receiving a customer's repair request, the company's after-sales service team will respond quickly, generally contacting the customer within 24 hours to understand the fault situation and develop a corresponding maintenance plan.

The company reserves sufficient spare parts for high-efficiency roller conveyors, including rollers, motors, reducers, transmission chains, belts, sensors and other common parts. When customers need to replace spare parts, we can provide original spare parts in time to ensure the quality and compatibility of spare parts.

We have a professional technical R&D and support team to provide customers with lifelong technical support services. If customers encounter any technical problems during the use of the equipment or need to upgrade the equipment, they can contact the technical support team at any time.