High efficiency roll grinding machine

1. Mechanical structure and transmission system: The bed is made of high-quality cast iron material and has been aging treated to effectively eliminate internal stress and ensure that deformation will not occur during long-term grinding. The high-precision ball screw and linear guide transmission system can achieve a feed resolution of micrometers or even smaller.

2. Measurement and feedback control system: Equipped with a high-precision online measurement system, it can monitor the size changes of the rolls during the grinding process in real time and feed the data back to the control system.

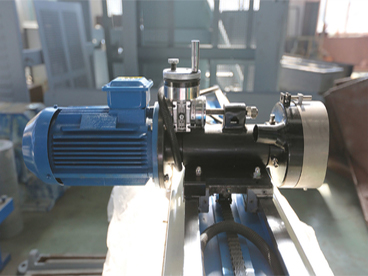

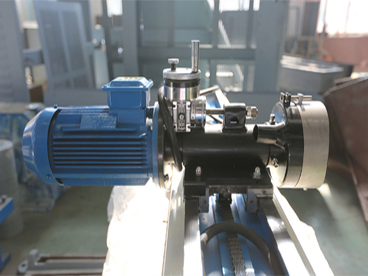

3. Power drive and high-speed grinding wheel spindle: Equipped with high-power motors and advanced drive technology, it provides sufficient power for the grinding wheel. The grinding wheel spindle adopts high-performance bearings and precise dynamic balancing technology, which can achieve high-speed rotation, with a maximum speed of thousands of revolutions per minute.

4. Grinding process: It has a rich grinding process database built in, and combined with intelligent algorithms, it can automatically generate the optimal grinding process plan and parameter settings based on the material, size, initial state and other parameters of the roll.

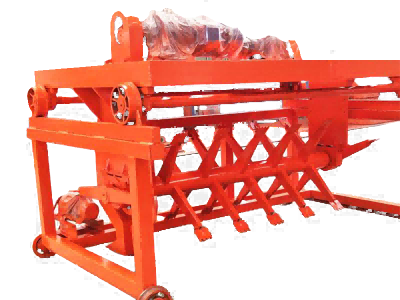

Roller grinding machines are usually composed of a frame, a transmission system, rollers, a roller shell, a feeding device, a discharging device, etc. During its operation, the raw materials enter the grinding area between the rollers through the feeding device. Through the high-speed rotation and relative movement of the rollers, the raw materials are continuously squeezed and ground, and finally form the required particle size and are discharged through the discharging device.

High-precision processing capability: With advanced measurement and control systems and high-precision core components, ultra-precision grinding of rolls can be achieved. For example, the cylindricity of the roll can be controlled within the micron level, and the surface roughness can reach below Ra0.2μm, meeting the stringent requirements of high-end manufacturing for roll precision and providing a key guarantee for the production of high-quality products.

High-efficiency grinding efficiency improvement: Through the optimized transmission system, high-power spindle drive and intelligent grinding process parameter setting, the grinding speed and efficiency are greatly improved. Compared with traditional roll grinders, the time for grinding the same roll can be shortened by 30% - 50%, effectively reducing production costs and improving the production efficiency and market competitiveness of enterprises.

Intelligent automatic control: With powerful CNC system and automatic functions, it can realize fully automatic operation of roll processing. From roll clamping, grinding parameter setting, grinding process control to automatic detection and data recording after processing, the whole process does not require excessive human intervention, reducing human operation errors and improving the stability and reliability of product quality.

Good compatibility and scalability: It is compatible with various types of grinding wheels and roller materials, and can be configured and upgraded according to customer needs. Grinding wheels of different sizes and hardness can be easily replaced to meet different grinding process requirements; at the same time, the machine tool has reserved a variety of interfaces and functional modules.