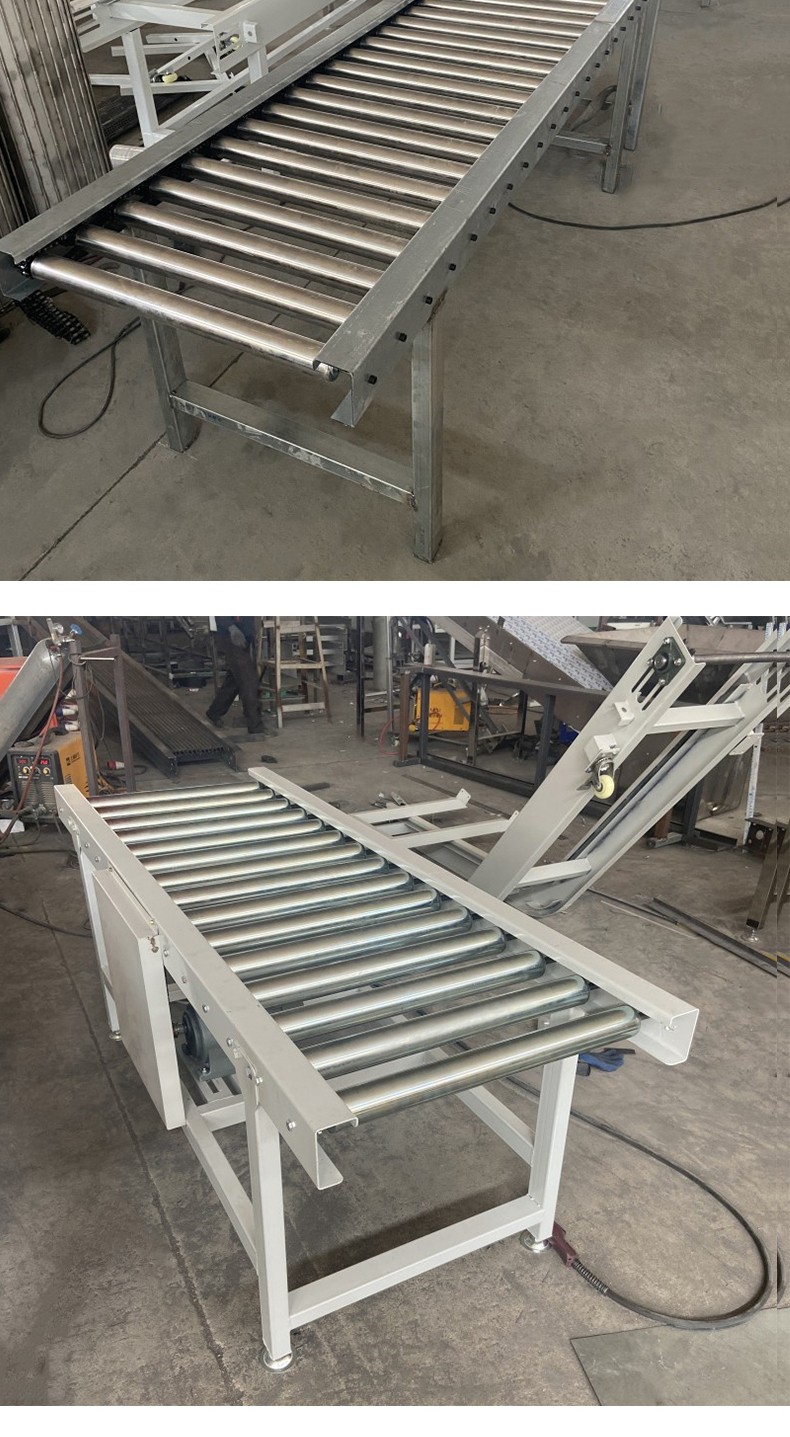

Fertilizer roller conveyor

1.It uses high-quality rollers and drive systems, which can run continuously for a long time without failure.

2. It has a high conveying speed and a large conveying capacity. Its reasonable roller layout and design enable fertilizers to move quickly and orderly on the conveyor.

3. It can be flexibly laid out and installed according to different production sites and process flows.

4. It has relatively low power consumption. The high-efficiency motor and optimized transmission system it uses can minimize energy consumption while ensuring the conveying capacity.

5. During the conveying process, due to its smooth conveying method and good adaptability, it can minimize the spillage, breakage and loss of fertilizers.

Fertilizer roller conveyor is a material conveying equipment specially used in the fertilizer industry. It plays a vital role in the production, storage and transportation of fertilizers. With its unique performance and advantages, it provides fertilizer companies with reliable and efficient conveying services.

With high conveying speed and large conveying capacity, it can complete the task of transporting a large amount of fertilizer in a short time. Its reasonable drum design and power configuration enable the fertilizer to move smoothly and quickly on the conveyor, greatly improving production efficiency.

The use of high-quality materials and exquisite manufacturing technology ensures that the equipment remains stable and reliable during long-term operation. The roller is made of high-strength and wear-resistant materials.

It can be used to transport fertilizers in different forms such as granular, powdery, and blocky. For granular fertilizers, the spacing and surface treatment of the rollers can ensure that the granules roll smoothly during transportation without getting stuck.

It can be flexibly laid out and installed according to the requirements of the production site and process flow. Whether it is straight-line conveying, curved turning conveying or climbing conveying, it can be achieved through reasonable design and combination.

Equipped with advanced speed control device, the delivery speed of fertilizer can be accurately adjusted according to production needs. In the process of fertilizer batching and mixing, it is necessary to accurately control the delivery amount of different raw materials.

The overall structure is well designed, and the main components are clearly visible, which is convenient for daily maintenance and upkeep. The rollers, bearings, transmission chains and other components are easy to disassemble and replace.

It is equipped with a series of safety protection devices, such as guardrails, emergency brake buttons, overload protection devices, etc. The guardrails separate the conveyor's operating area from the operator to prevent accidental contact with dangerous parts such as rollers.