Urea mill

Working principle

Compact structure, simple operation and durable

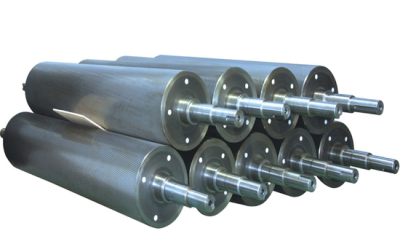

Urea crusher is mainly the use of high-speed roller and gravure plate gap grinding shear, the size of the gap determines the degree of material crushing, roller speed and roller diameter can be adjusted, urea into the body after the impact of the wall and baffle and broken, and then through the roller and gravure plate between the rack ground into powder. The clearance of the concave plate is adjusted by the adjusting mechanism in the range of 3-12 mm to adjust the degree of grinding, and the feed port adjusting mechanism can control the size of the production.

Equipment advantage

Compact structure, simple operation and durable

Easy to operate: simple structure, no wearing parts, no dust, no auxiliary dust removal equipment.

High crushing efficiency: the two rolls of the mechanical urea mill rotate opposite to each other, squeezing and crushing the material, the crushing speed is fast, and the roller is not sticky.

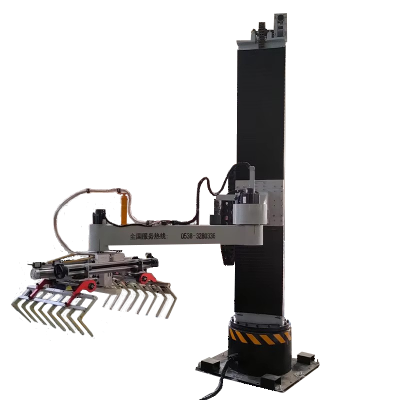

Not easy to plug: the urea crusher feed port is equipped with a block tooth roller, even if there is a small amount of caking will not plug, continuous work.

Bremetz mechanical urea mill is a medium-sized horizontal cage mill. It can crush a variety of single fertilizers with water content below 40%, especially suitable for materials with high hardness. The machine is designed according to the principle of impact crushing. The two groups of cage bars inside and outside rotate opposite to each other at high speed, and the material is crushed by the impact of the cage bars from inside out.