Automatic disc mixer

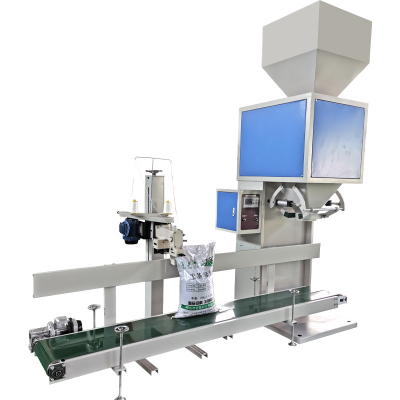

1.Automatic disc mixer is usually equipped with advanced feeding system, which can automatically add various materials according to the preset amount.

2. It has intelligent mixing control system. The operator can easily set the mixing time, speed, direction and other parameters on the operation panel.

3. The disc-shaped mixing container with specially designed mixing paddle can form good convection and circulation of materials during mixing.

4. Due to the high degree of automation, the mixing parameters can be accurately controlled, so the precise mixing degree can be achieved according to different material characteristics and product requirements.

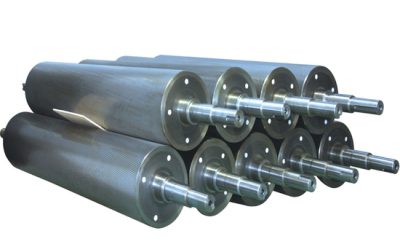

5. Focus on energy saving in motor selection and transmission system design. Use high-efficiency motors, and reduce energy consumption through reasonable transmission ratio and power matching.

The disc-shaped mixing container is used. This design enables the material to form good convection and circulation during the mixing process, effectively avoiding the accumulation of materials in the mixing dead corners and ensuring the uniformity of material mixing.

It has automatic feeding, unloading and mixing control functions. The operator only needs to set the relevant parameters on the operation panel, such as mixing time, speed, material addition amount, etc., and the machine can automatically complete the entire mixing process without frequent manual intervention, which greatly improves production efficiency and reduces labor intensity.

The combination of specially designed stirring paddle and disc container can form a complex flow field during the stirring process, achieving full mixing of materials. Whether it is powder, granular or paste materials, they can be evenly stirred to ensure the stability of product quality.

The use of efficient motors and optimized transmission systems can reduce energy consumption while ensuring the mixing effect. Some models of automatic disc mixers are also equipped with variable frequency speed regulation function, which can automatically adjust the motor speed according to the actual mixing needs to further improve energy efficiency.

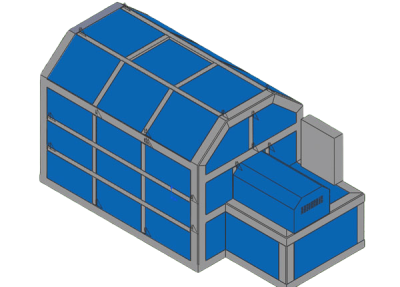

It is equipped with complete safety protection devices, such as emergency stop button, guardrail, protective cover, etc., to prevent operators from contacting moving parts and avoid accidental injuries.