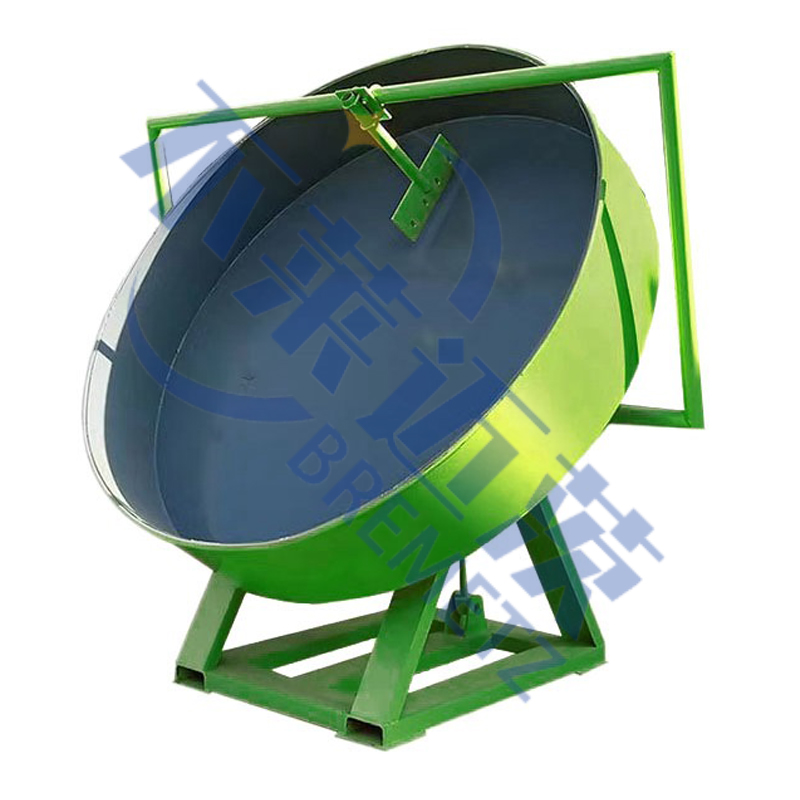

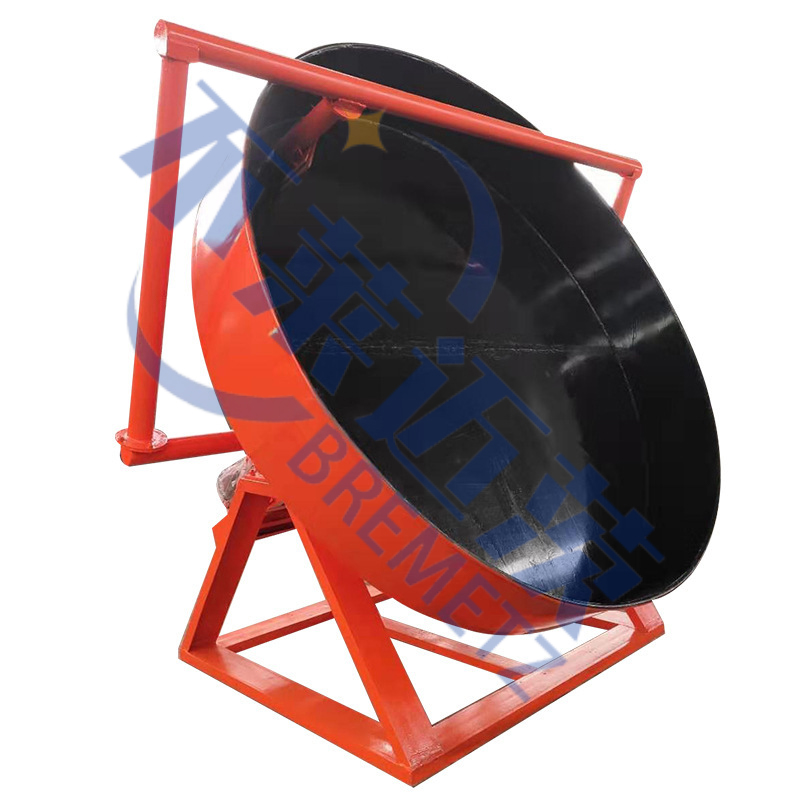

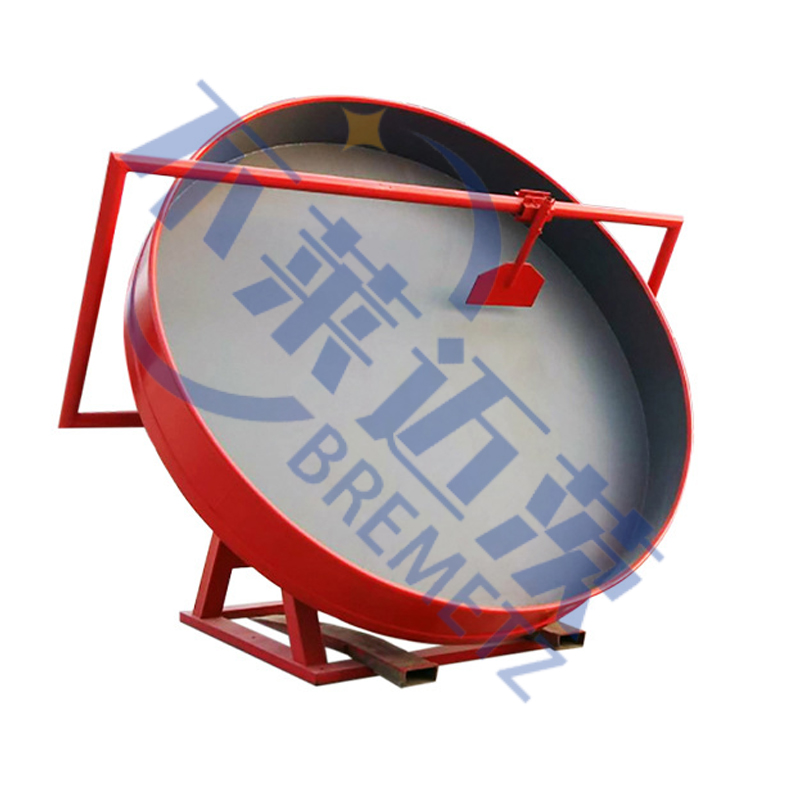

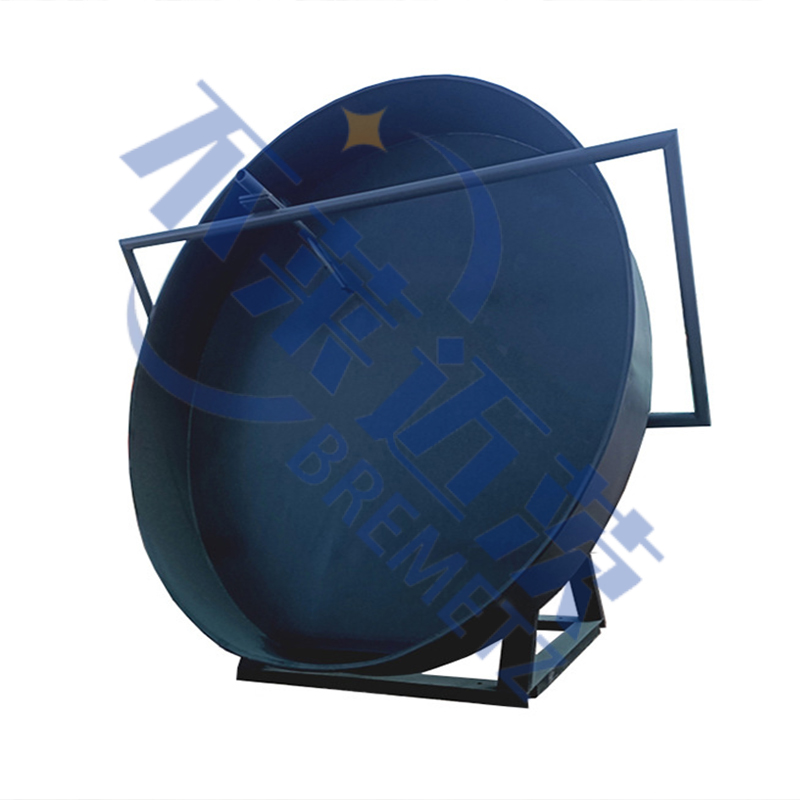

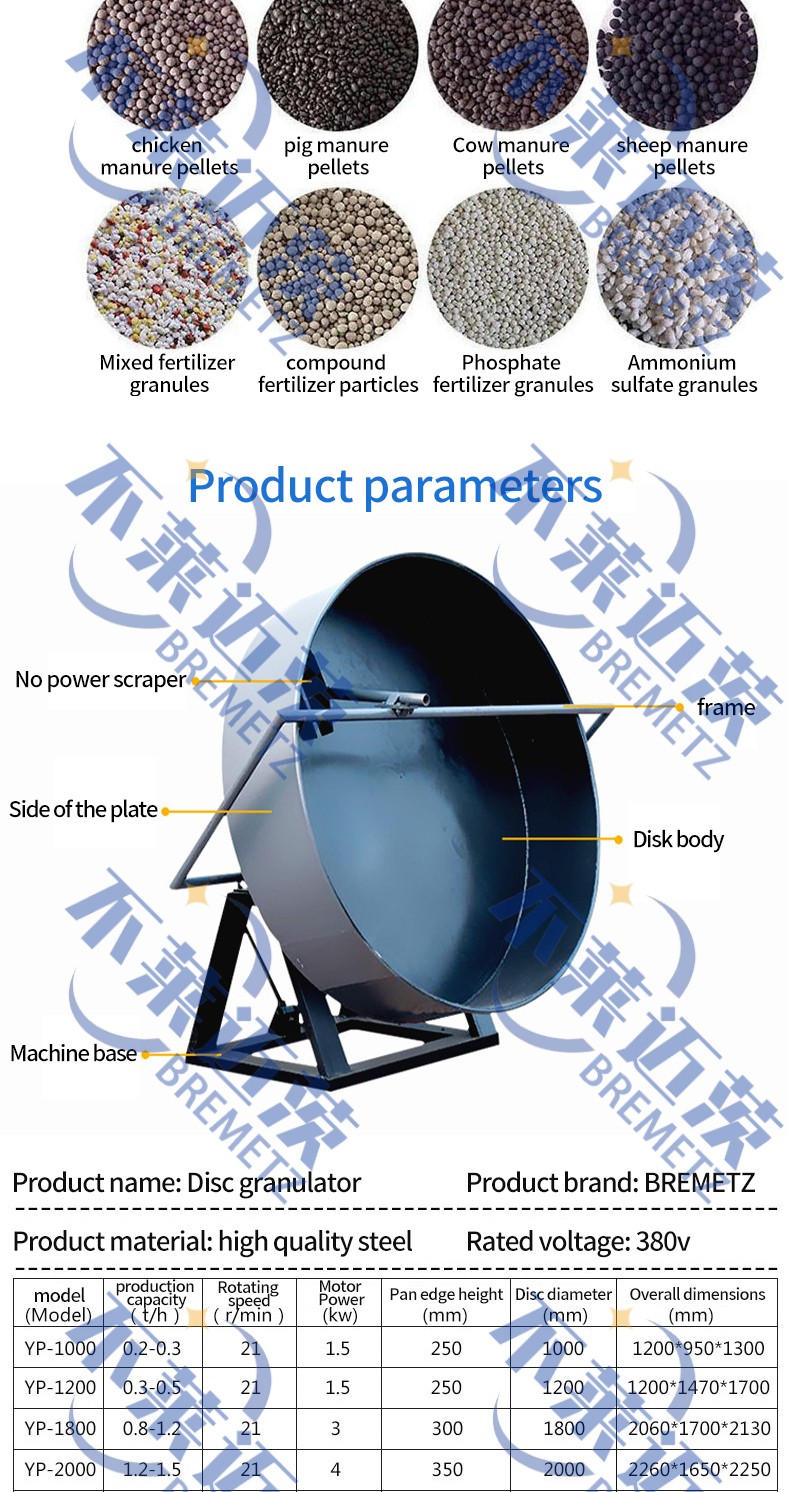

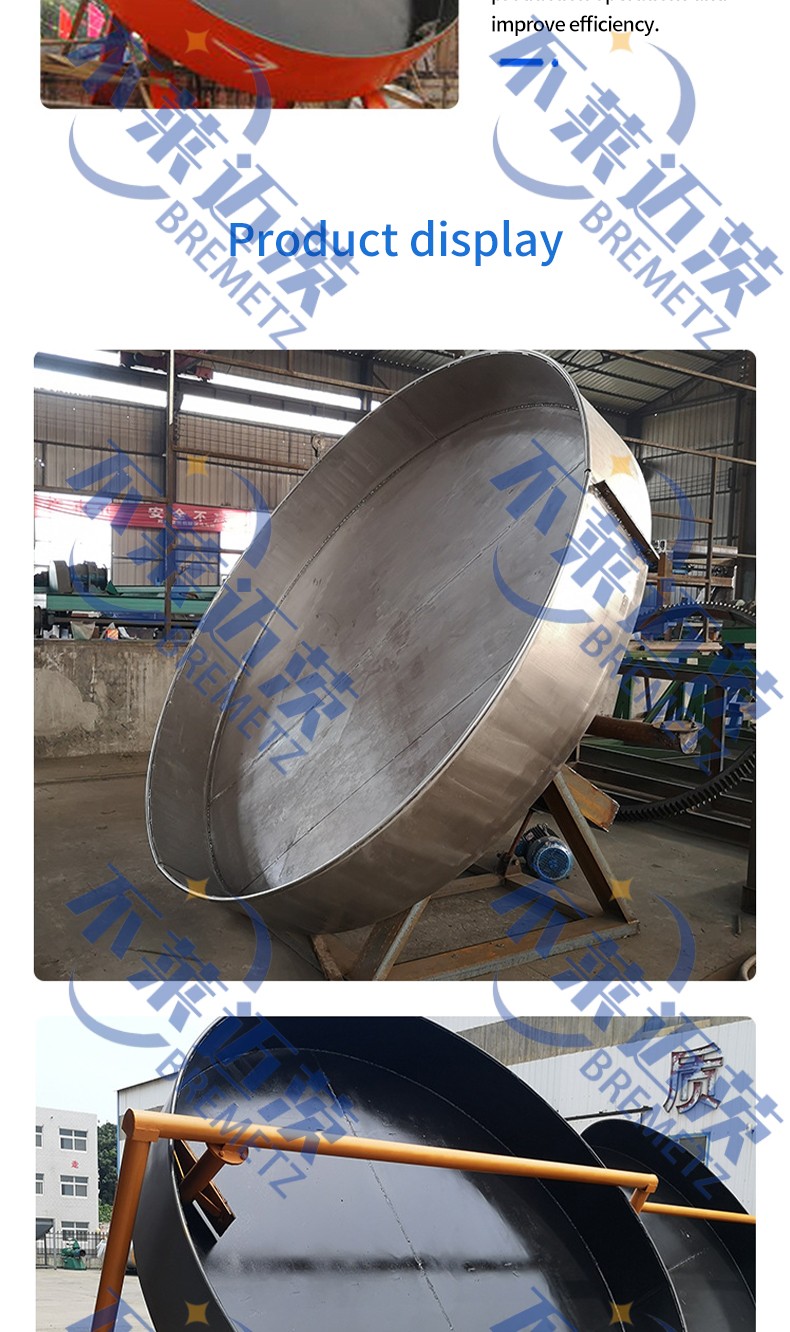

High efficiency fertilizer granulator

1. Its optimized rotation speed and unique material distribution design can increase the output by 30% - 50% compared with traditional equipment.

2. It can produce granular fertilizers with uniform particle size and regular shape. The particle strength is high.

3. It has strong compatibility with various fertilizer raw materials, whether it is organic materials or chemical raw materials, it can effectively granulate.

4. The design focuses on energy utilization efficiency, and reduces unnecessary energy consumption by optimizing the transmission system and power configuration.

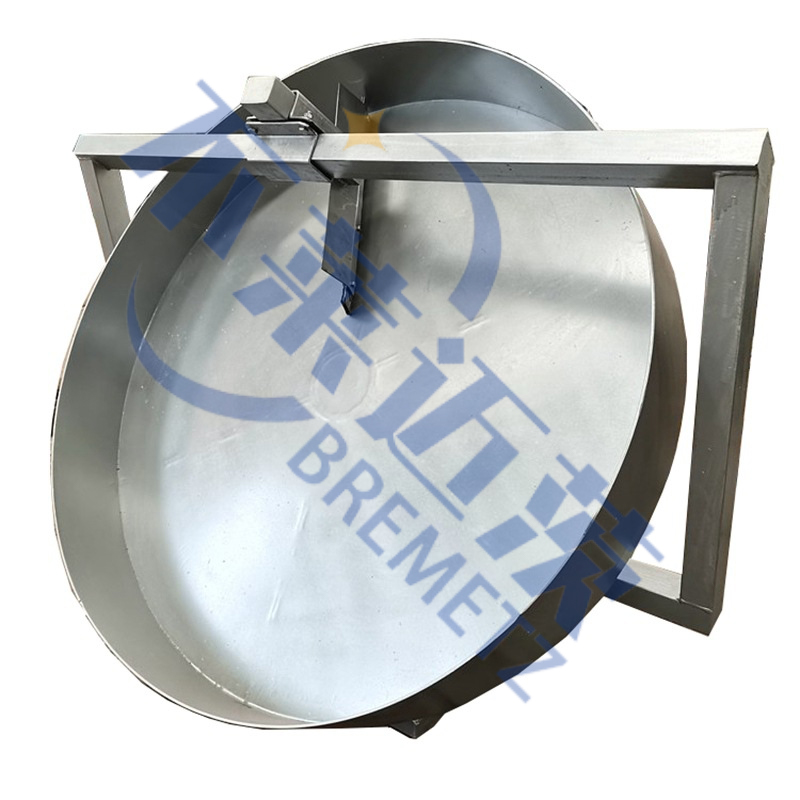

5. The structural design is reasonable, the key components are easy to disassemble and replace, and daily maintenance only requires simple cleaning, lubrication and inspection.

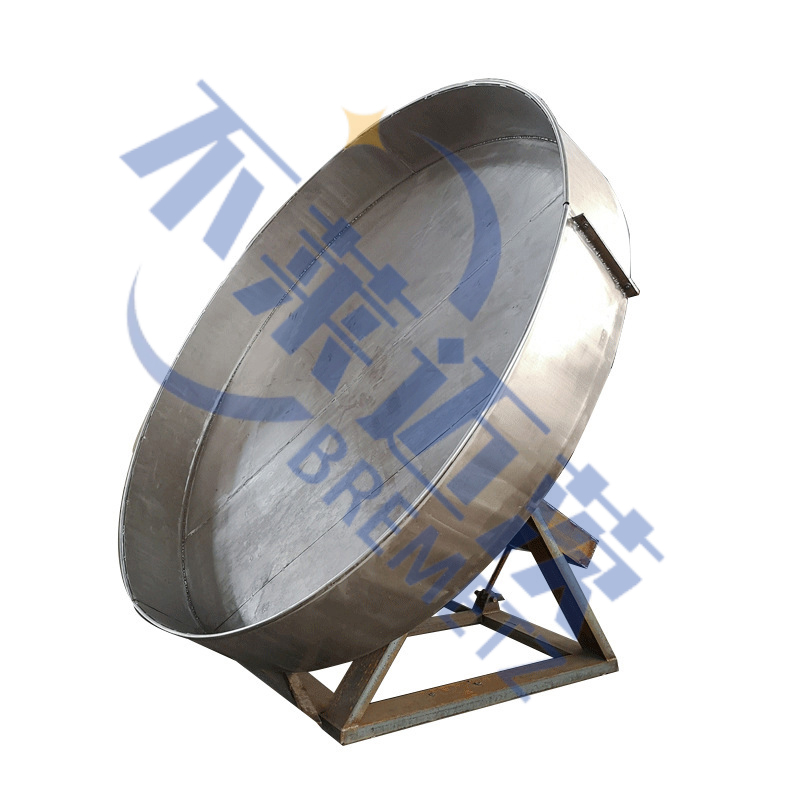

The high-efficiency fertilizer granulator is a fertilizer production equipment that integrates advanced technology and innovative design, aiming to meet the needs of modern agriculture for high-quality and high-efficiency fertilizer production.

It can produce granular fertilizers with uniform particle size and regular shape. The granules are strong and not easy to break during transportation and storage, ensuring the stable release of fertilizer nutrients and improving fertilizer utilization.

It can adapt to a variety of fertilizer raw materials, including livestock and poultry manure, straw, sludge, chemical fertilizers and other organic and inorganic materials, providing enterprises with a wider range of raw material choices and reducing production costs.

The optimized structure and advanced transmission system greatly improve production efficiency. Compared with traditional granulators, the output can be increased by 30% - 50%, meeting the needs of large-scale production.

The use of energy-saving motors and optimized power configuration effectively reduces energy consumption. Compared with similar products, energy consumption can be reduced by 20% - 30%, which is in line with the concept of green production.

The user-friendly operation interface, intuitive parameter settings and simple operation procedures allow operators to master the operation after a short period of training, thus reducing labor costs and the risk of operational errors.

The structure is well designed and key parts are easy to disassemble and replace. The equipment has a low failure rate and short maintenance time, ensuring the continuity of production.