Flat die pelletizing machine

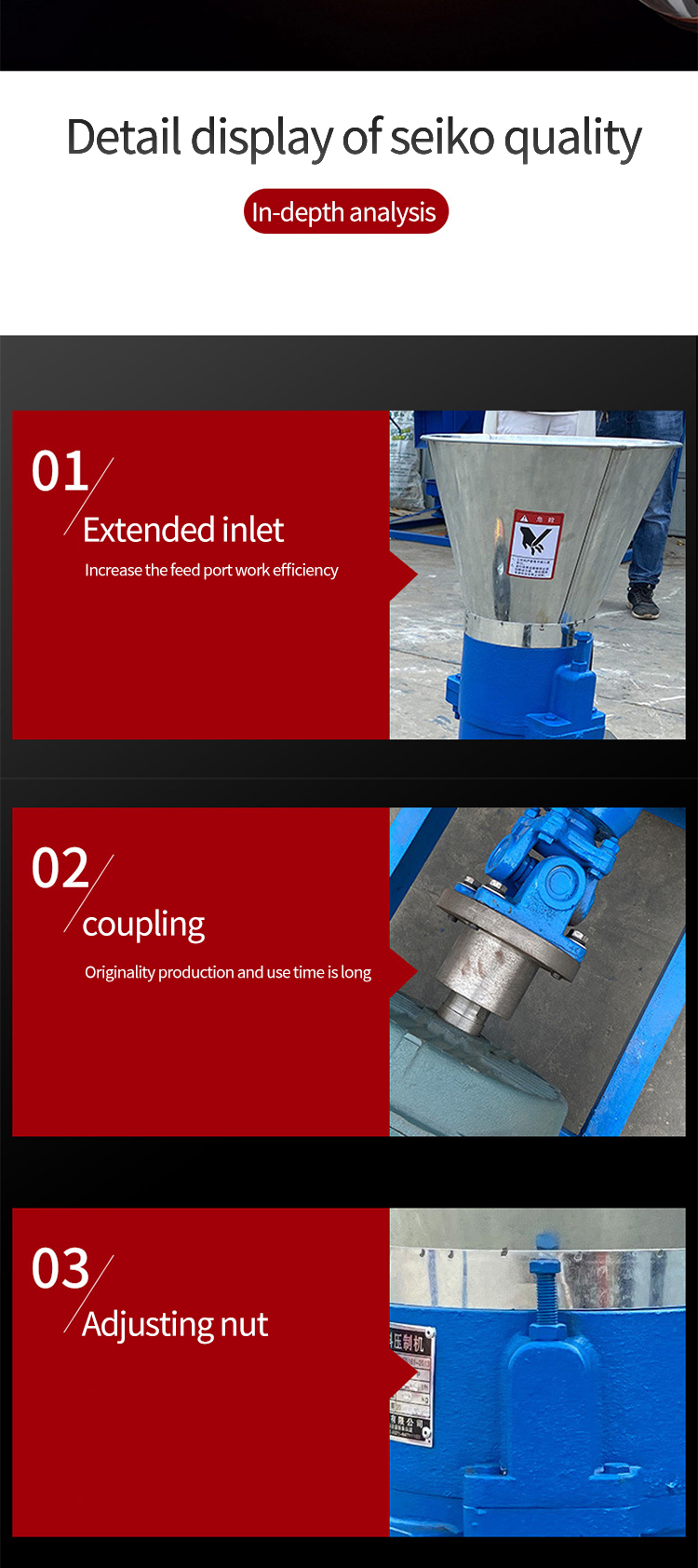

1. Compact structure and cost-effectiveness: The overall design is exquisite and compact, with a small footprint, and the production line can be built in a limited space.

2. Wide adaptability to materials: It has strong compatibility with the physical properties of materials, and can process both fiber-rich biomass raw materials and powdered feed efficiently.

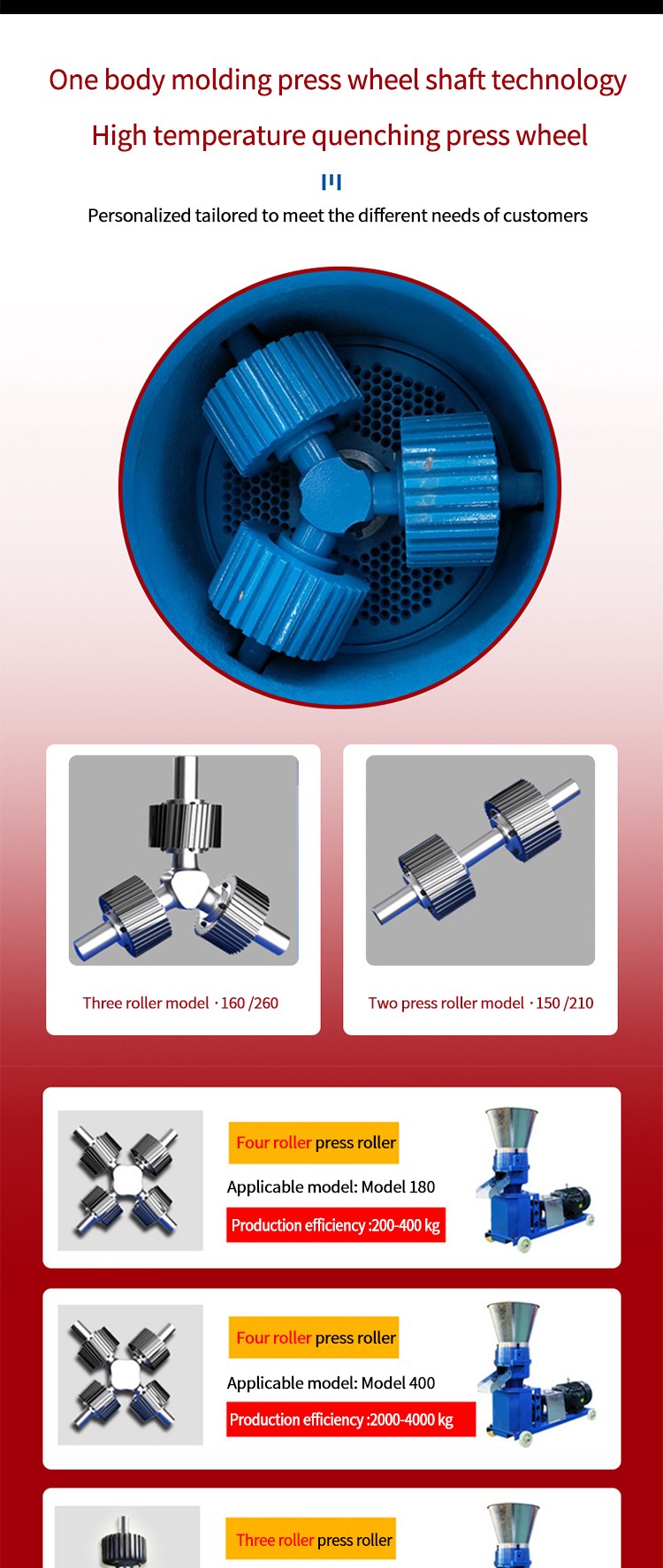

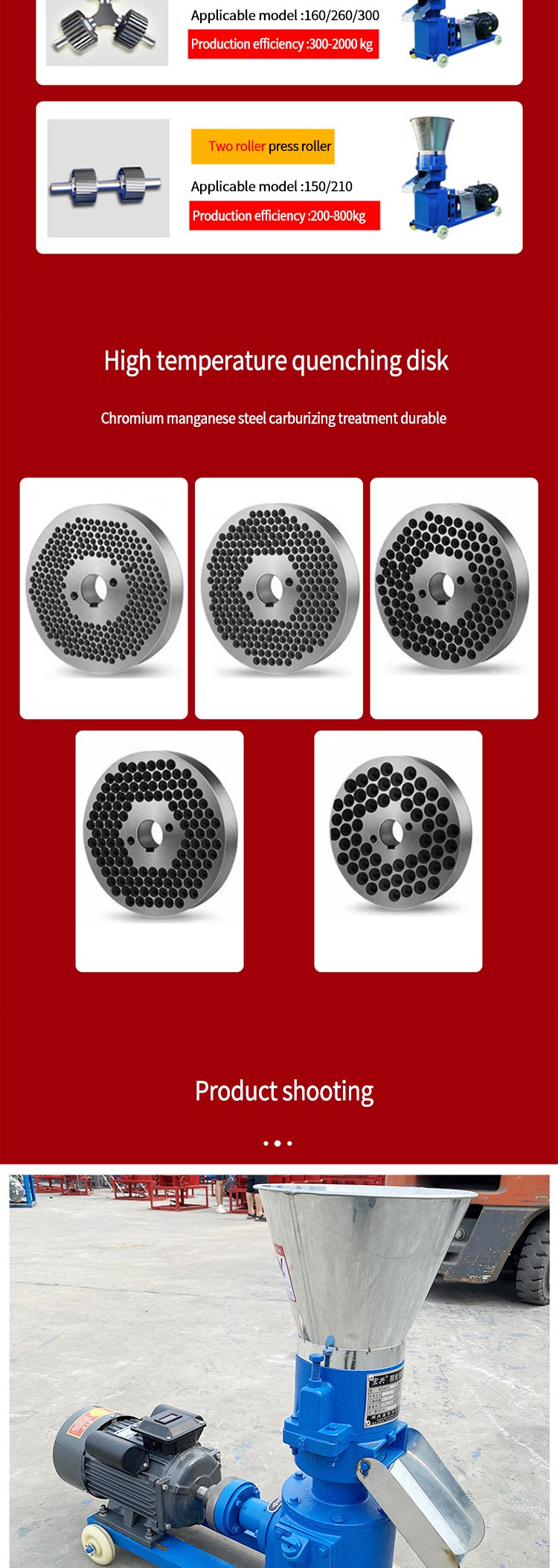

3. Efficient and stable particle forming: The flat die and the roller work together. The roller applies uniform and stable extrusion force to the material during rotation, so that the material can pass smoothly through the dense die holes on the flat die.

4. Easy and convenient operation: The operation interface is clear and intuitive, integrating the concept of ergonomics, and the equipment start and stop, speed control, and material feed amount adjustment are easy to operate.

5. Excellent energy-saving and low-consumption performance: The power transmission system is efficiently optimized, and the motor energy is efficiently converted into the working power of the roller, reducing energy loss in the transmission link.

6. Outstanding environmental protection characteristics: The equipment has good sealing, and dust escape is suppressed to the maximum extent during operation. Combined with the matching dust collection device, the dust concentration in the workshop can be controlled within the safety and health standards.

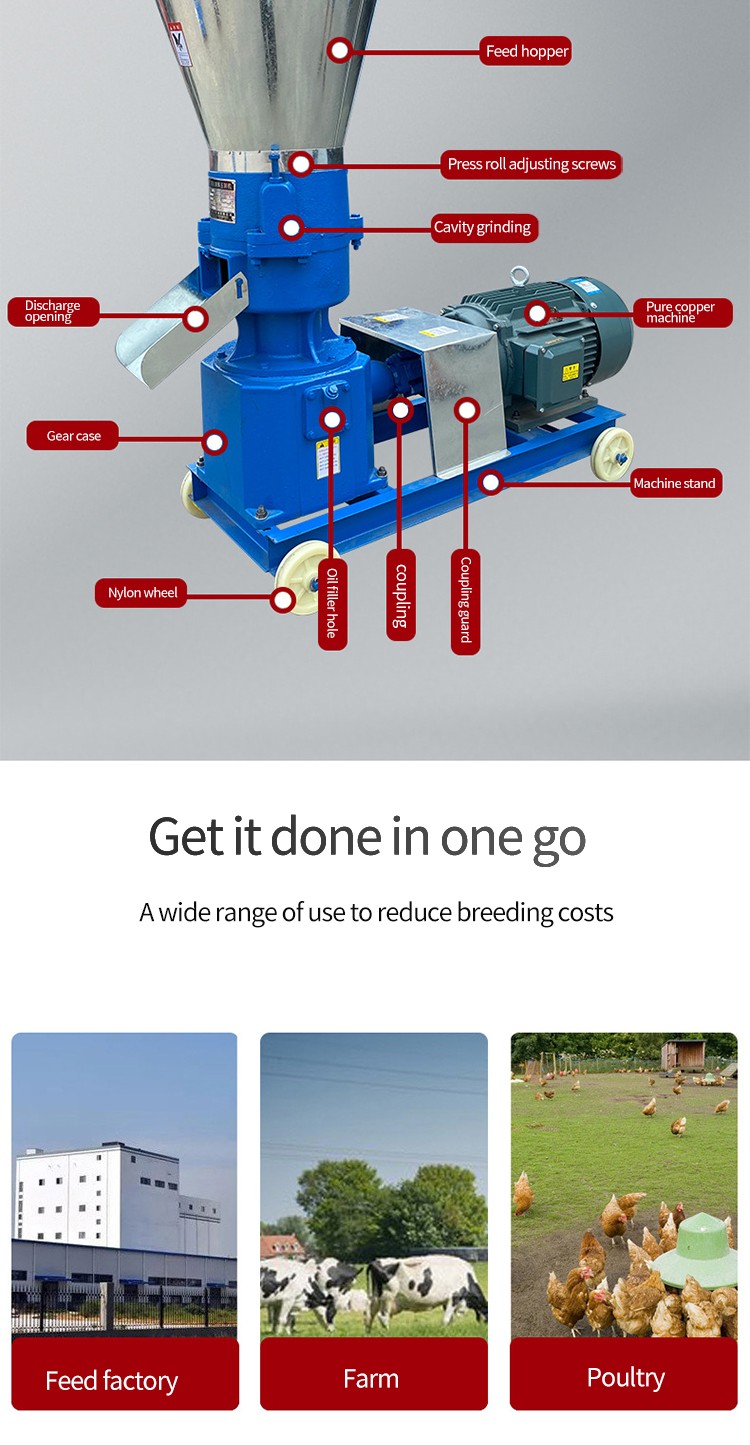

Flat Die Pelletizing Machine is mainly composed of the machine frame, power transmission system, flat die plate, roller assembly, feeding device, discharging system and electrical control system.

The material enters the equipment from the feeding device and is pushed to the top of the flat die plate by the screw feeder. At this time, driven by the power transmission system, the pressure roller makes uniform circular motion on the surface of the flat die plate. The material is subjected to strong extrusion force between the pressure roller and the flat die plate, is compacted and forced to pass through the die hole on the flat die plate. At the die hole outlet, the material forms particles with specific shapes and sizes due to sudden pressure reduction and volume rebound. The formed particles are scraped off the flat die plate by the scraper plate and finally collected and output by the discharging system.

High particle molding quality: Through precise mechanical processing and optimized process design, the particles are regular in shape and uniform in size, with errors controlled within a very small range. The surface is smooth and the internal structure is compact. In long-term storage, frequent transportation and practical applications, they show excellent resistance to breakage and pulverization, ensuring stable and reliable product quality.

Wide material applicability: It has a high acceptance of material types and physical properties, and can process biomass containing a large amount of fiber (such as various types of straw, wood chips, hay), fine powdered feed raw materials, organic fertilizer mixtures, etc. Even if the moisture content and coarseness of the material fluctuate, it can be processed smoothly through appropriate parameter adjustments, thereby broadening the boundaries of the company's product development.

Efficient and energy-saving operation: Advanced transmission architecture and power matching mechanism reduce power transmission loss and equipment energy consumption. Compared with some traditional granulation equipment, energy saving can reach 20% - 30% at the same output. Long-term operation helps enterprises reduce costs and conforms to the trend of environmental protection and energy-saving production.

Easy operation and maintenance: The operation panel is user-friendly, and the function buttons and parameter displays are clear and intuitive. Operators can master equipment start and stop, parameter adjustment and other operations after a short period of training. The equipment is easy to disassemble and assemble, and wearing parts can be easily replaced. Regular cleaning and maintenance take a short time, reducing the operation and maintenance cost of the equipment throughout its life cycle.

Flexible capacity control: According to market orders, raw material supply and other conditions, the motor speed, feed speed, roller pressure and other parameters can be easily adjusted to flexibly control the equipment output, achieve flexible changes in production capacity in a large range, and adapt to the needs of production in the off-season and peak season.

Flexible capacity control: According to market orders, raw material supply and other conditions, the motor speed, feed speed, roller pressure and other parameters can be easily adjusted to flexibly control the equipment output, achieve flexible changes in production capacity in a large range, and adapt to the needs of production in the off-season and peak season.

Application areas:

Biomass energy industry: converting agricultural and forestry waste into biomass pellet fuel, helping clean energy to replace traditional fossil fuels, realizing waste resource utilization, and alleviating energy shortages and environmental pressures.

Feed processing industry: manufacturing complete feed or feed additive pellets for poultry, livestock, and aquatic products to ensure balanced nutrition, good palatability, and storage resistance of feed, and improve breeding efficiency.

Organic fertilizer manufacturing field: making organic materials into pellet fertilizers for easy storage, transportation, and fertilization, improving soil structure, and increasing crop yield and quality.

We have set up a 24-hour technical consultation hotline staffed by senior technical experts. If customers encounter difficulties in material adaptation, parameter adjustment, capacity optimization, etc. during the use of equipment, they can call at any time to get professional and accurate answers. Experts can also provide customized process improvement suggestions and new product development direction guidance based on customers' production bottlenecks, helping customers upgrade their technology and expand their business.