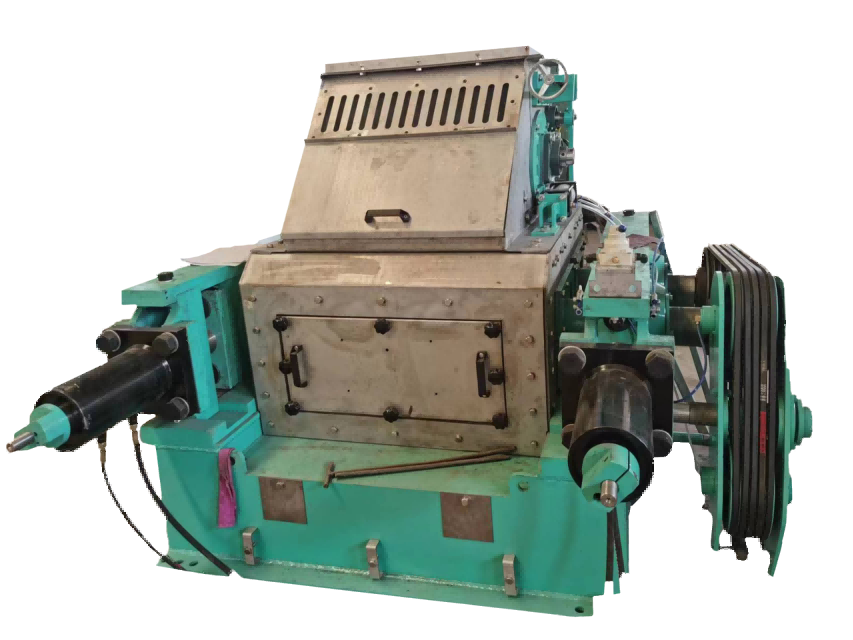

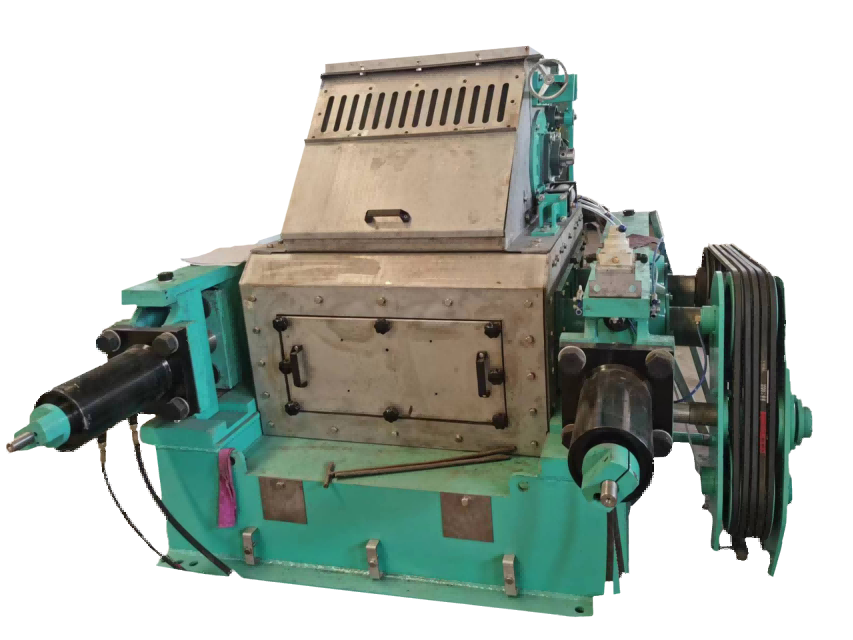

Corn flakes manufacturing equipment

1. Efficient production: The equipment adopts advanced processing technology, such as extrusion puffing, tableting and other technologies, which can quickly convert corn raw materials into corn flakes and improve production efficiency.

2. Stable product quality: Through precise temperature and pressure control and automated processing procedures, the taste, thickness, crispness and other quality indicators of each corn flake are ensured to be consistent.

3. Nutritional retention: During the processing, the nutrients in corn, such as dietary fiber, vitamins, minerals, etc., can be well retained.

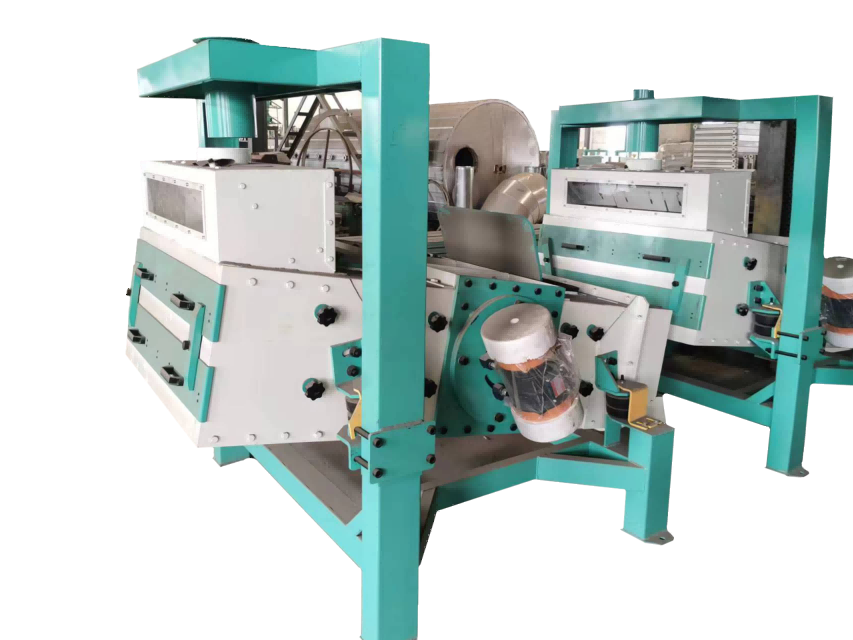

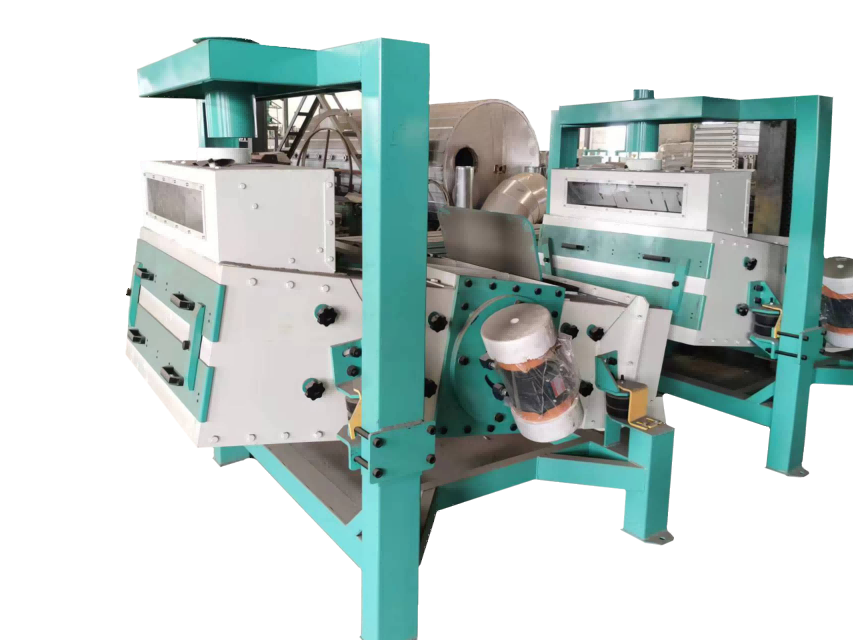

4. High degree of automation: Equipped with advanced control systems, such as touch screen centralized control, etc., it realizes fully automated operation from raw material feeding, processing to finished product packaging.

5. Energy saving and consumption reduction: The use of energy-saving motors, heating devices and other equipment components, as well as optimized process flow design, effectively reduces energy consumption.

Efficient output: Automated assembly lines connect various units in series and work together seamlessly. Large-scale equipment can produce several tons of products per day, far exceeding traditional manual or semi-mechanical production. It is adaptable to large-scale industrial needs and seizes market opportunities.

Constant quality: The temperature control, pressure control and other systems are precise, ensuring that the corn flakes’ color, thickness (error can be as low as ±0.1 mm), taste (consistent crispness and crackling sound) and other indicators are stable batch by batch, in line with the brand’s standardization requirements.

Easy to operate: the touch screen integrates PLC control, the visual interface starts and stops with one button, and the parameters can be adjusted quickly on demand. New workers can get started after a few days of training, reducing labor costs and improving operational efficiency.

Easy maintenance: modular structure, easy replacement of parts, wear-resistant materials, convenient daily cleaning and maintenance, efficient troubleshooting and repair, and extended equipment service life.

Applicable to multiple scenarios:

Large-scale production in the food industry: Large food factories rely on its high efficiency and stability to mass-produce classic original and multi-flavor corn flakes, filling supermarket shelves and e-commerce platforms, radiating the national and even global markets.

Special homemade food and beverage stores: Small equipment is suitable for restaurants and cafes, and fresh corn flakes are added to breakfast and dessert menus, made and sold on the spot, attracting customers with fresh taste and customized flavors.