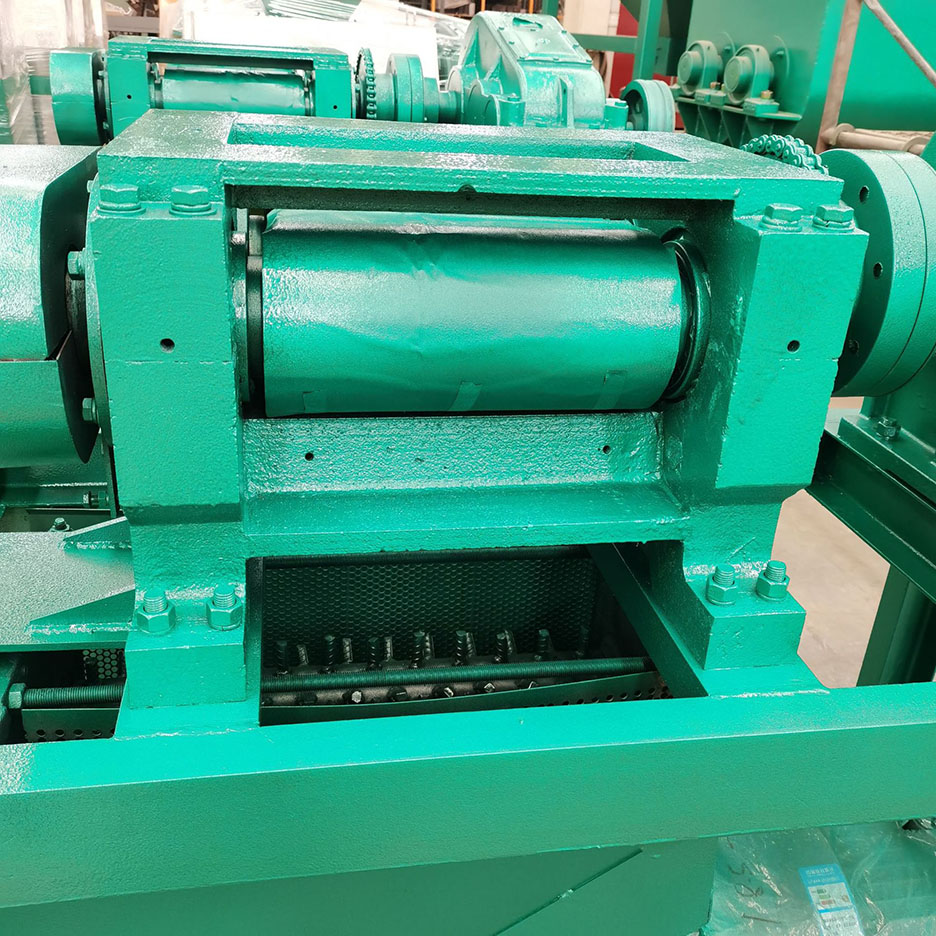

Automatic double roller extrusion granulator

1. The double-roll extrusion granulator shows excellent granulation effect when processing materials such as ammonium carbonate and monoammonium phosphate. The ball formation rate is significantly improved, and there is no need for drying, which saves investment and has a quick return.

2. The machine adopts normal temperature granulation technology, does not require a drying process, and achieves one-time molding, further reducing the investment cost.

3. The extrusion granulator has a small power demand and no three wastes are discharged, ensuring stable and reliable operation and easy maintenance. At the same time, the reasonable process layout and simple operation process significantly reduce the production cost.

4. The double-roll granulator has a wide range of raw material adaptability. Whether it is compound fertilizer, medicine, chemical industry, feed, or raw materials in coal, metallurgy and other fields, it can be efficiently granulated. In addition, it can also produce compound fertilizers of different concentrations and types, such as organic fertilizer, inorganic fertilizer, biological fertilizer and magnetic fertilizer, etc.

The double-roll extrusion granulator adopts the principle of dry granulation. Its working process involves the material being extruded to form a mass or sheet in a non-adhesive state, followed by crushing and screening to finally obtain a granular product.

The double-roll extrusion granulator is a key equipment for ammonium chloride, ammonium sulfate, and compound fertilizer granulation. It has advanced technology, reasonable design, compact structure, novelty and practicality, low energy consumption, and is matched with corresponding equipment to form a small production line, which can form a continuous and mechanized production with a certain capacity. It adopts a eugenics formula, does not require drying, and is produced at room temperature. The product is rolled and formed at one time, so that the product quality meets the technical index requirements of compound fertilizers. It is a replacement product for energy saving and consumption reduction in the compound fertilizer industry for the production of high, medium and low concentration special compound fertilizers for various crops.

The double-roll extrusion granulator is a granulation equipment. It adopts a non-drying room temperature process for production, one-time molding, and an output of 800KG-1000KG/hour. The equipment has low investment, quick results, and good economic benefits.

The complete set of equipment has a compact layout, scientific and reasonable, and advanced technology. It saves energy and reduces consumption, does not discharge three wastes, has stable operation, reliable operation, and is easy to maintain. The raw materials have wide adaptability and are suitable for granulation of various raw materials such as fertilizers, medicines, chemicals, and feeds, and the product granulation rate is high.

It can produce compound fertilizers of various concentrations and types (including ammonium chloride, ammonium sulfate, organic fertilizers, inorganic fertilizers, biological fertilizers, magnetic fertilizers, etc.). In particular, the granulation of rare earth, potash fertilizer, and ammonium carbonate series compound fertilizers has filled the domestic gap and is at the leading level in China.