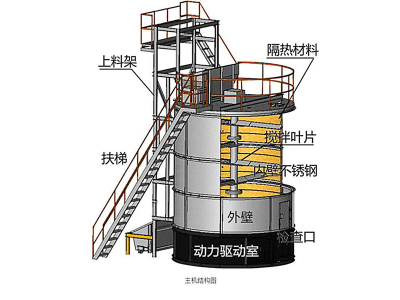

Agitator Granulator

1. The stirring paddle stirs fully in the cylinder to ensure that all kinds of raw materials can be evenly mixed together.

2. During the stirring process, the materials gradually agglomerate to form particles under the action of appropriate humidity and binder.

3. Parameters such as stirring speed, stirring time, and temperature can be flexibly adjusted according to different material characteristics and granulation requirements.

4. It can adapt well to various different formulas. The ideal granulation effect can be achieved by adjusting the equipment parameters.

5. Since the stirring granulation process is relatively gentle, it is very friendly to some heat-sensitive materials or materials with special physical and chemical properties.

The stirring granulator is usually an inclined or horizontal disc with a stirrer installed in the disc. The powder in the disc is mixed with the liquid binder to form granules under the push of the stirrer.It uses the mechanical force generated by the rotation of the agitator to make the materials constantly turn, mix and collide in the container, and at the same time add a proper amount of liquid adhesive to gradually agglomerate the powder into granules.

It can process materials of various properties, such as powder, granules, fibers, etc. It can also achieve good granulation effects on sticky materials, heat-sensitive materials and materials that are difficult to granulate.

By properly selecting the type and speed of the agitator, the materials can be mixed evenly, and the resulting particles have regular shapes, uniform sizes, and good fluidity, which is beneficial for subsequent processing and use.

The structure of the equipment is relatively simple, and the operation process is easy to master. It does not require complex technology and a large number of operators, which reduces the difficulty and cost of production.

Compared with high shear granulators, stirring granulators generate less shear force and cause less damage to the structure and performance of materials during the granulation process. They are especially suitable for materials that are sensitive to shear force.