Weighing type granule bag packaging machine

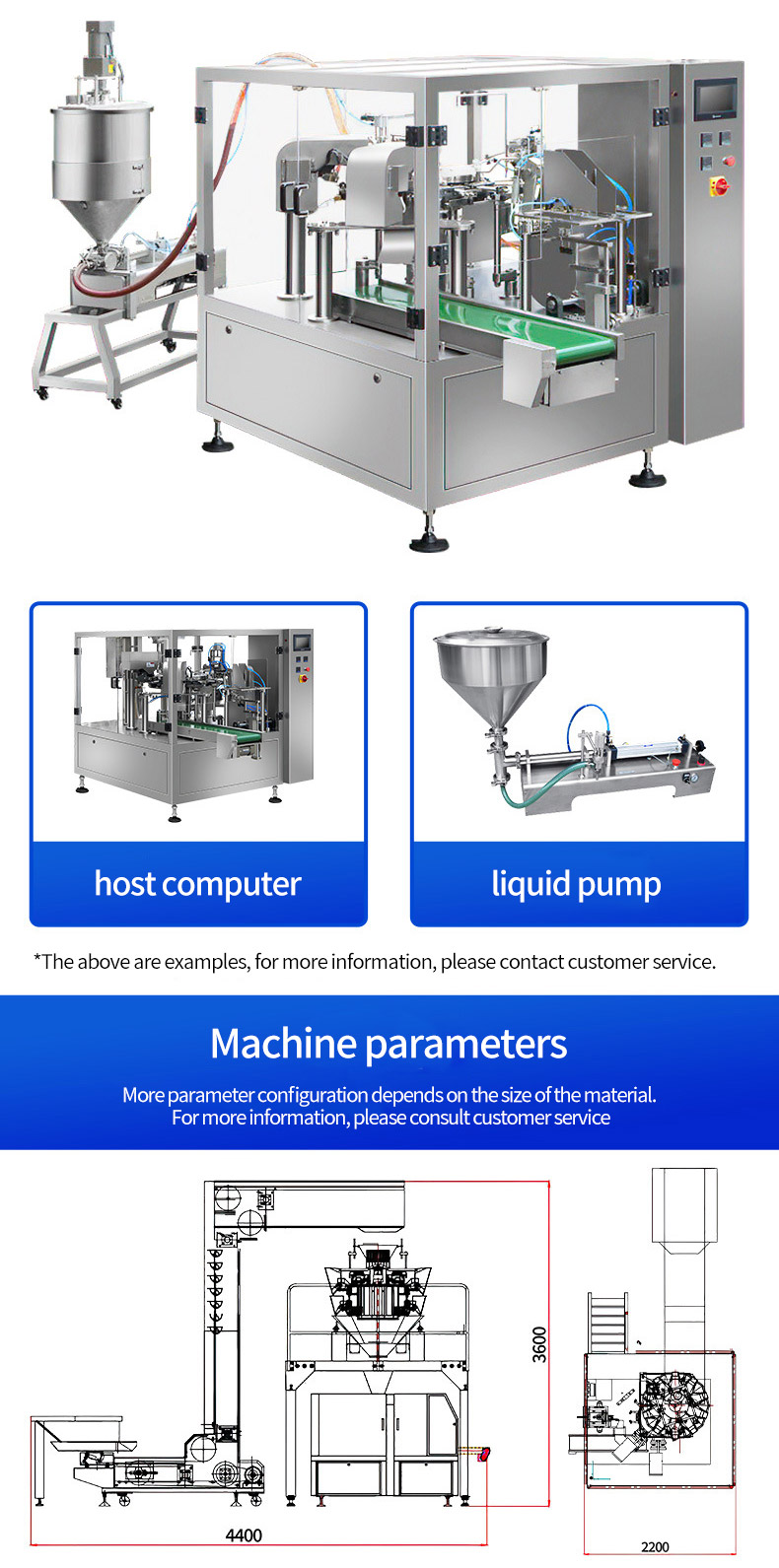

1. The use of advanced weighing sensors can accurately measure the weight of granular materials to ensure the accuracy of the amount of material in each packaging bag.

2. With automatic calibration and compensation functions, it can monitor and adjust the weighing data in real time during operation to ensure the accuracy and stability of measurement.

3. Equipped with PLC control system and advanced transmission device, it realizes the full automation of a series of packaging processes from material conveying, metering, filling to sealing.

4. The use of high-quality motors, reducers and other key components ensures the stability and reliability of the equipment under long-term high-speed operation.

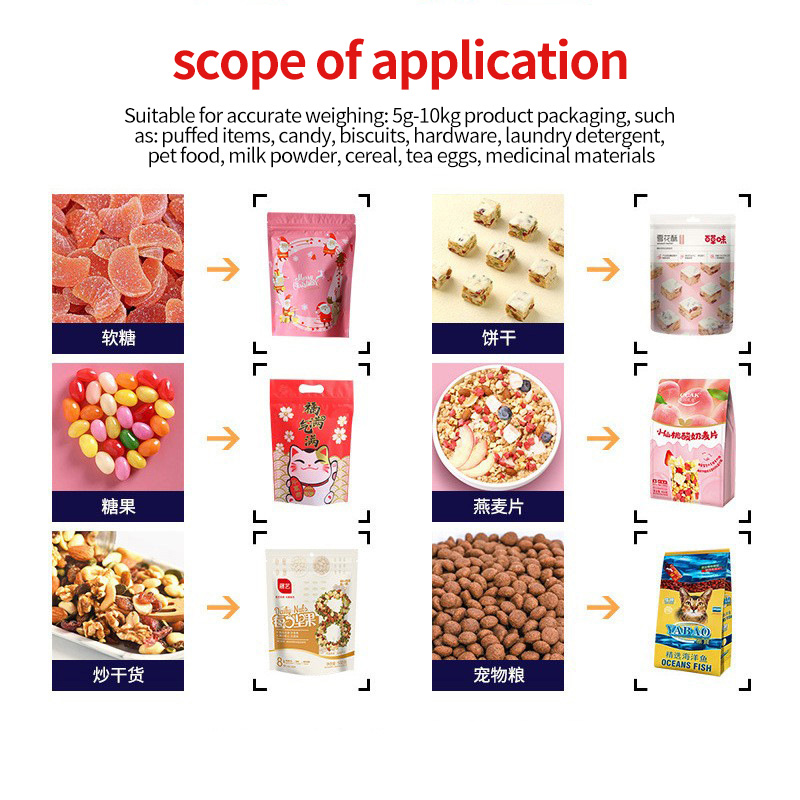

5. Suitable for various granular materials, whether regular or irregular shaped particles, as well as granular materials with different fluidity and density, can achieve good packaging effects by adjusting equipment parameters.

As an elite team in the field of granular material packaging, Weighing type granule bag packaging machine integrates cutting-edge weighing technology, automatic control and sophisticated mechanical design, and is committed to providing ultra-precise, efficient and highly adaptable granule packaging solutions for many industries such as food, chemical, and agriculture.

With the help of high-precision weighing system and intelligent compensation mechanism, the weight of each bag of particles is guaranteed to be accurate, which not only avoids material waste, but also ensures the stable quality of end products and protects the brand reputation.

It can freely move between the granular materials of food, chemical, pharmaceutical, agricultural and other industries. Whether it is white sugar with excellent fluidity, chemical raw materials with slightly stronger viscosity, or pharmaceutical granules with strict hygiene requirements, perfect packaging can be achieved through simple parameter adjustment.

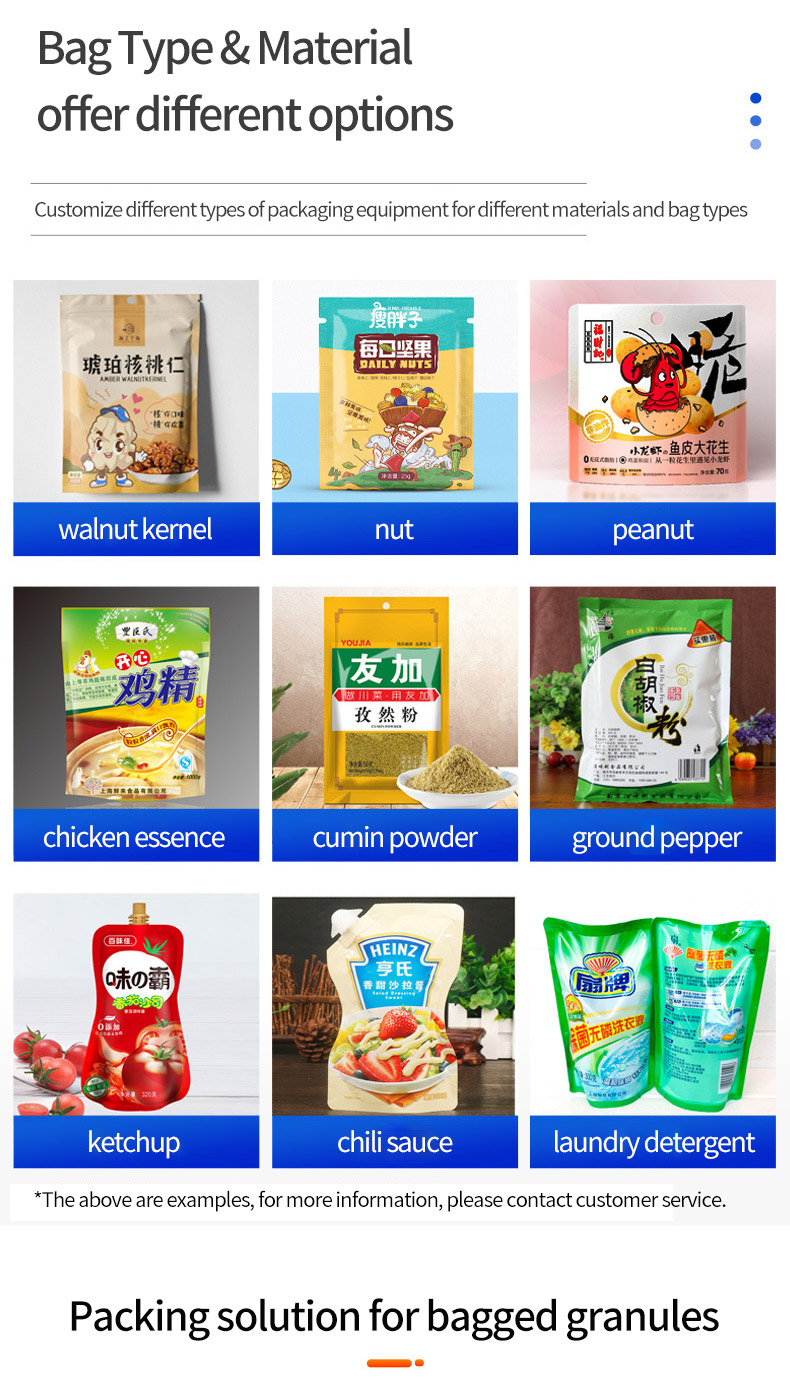

A wide variety of bag options, combined with customized services, make product packaging fit the market trends and customer personalized demands, enhance product recognition and market competitiveness, and add wings to brand communication.

High-speed and stable packaging performance helps enterprises seize the initiative in fierce competition, significantly reduce labor and time costs, quickly respond to market orders, and achieve increasing scale benefits.

Multiple safety protection facilities build a solid safety line, and emergency stop, safety light curtain, and overload protection are all available to fully protect the personal safety of operators and meet the requirements of safety production regulations.

The closed packaging structure works together with the dust collection device to lock in dust, protecting the environment and the health of operators; the energy-saving design runs through the motor and control system to reduce energy consumption and take the path of sustainable development.