Valve port packaging machine

1. Equipped with high-precision metering devices, it can accurately control the weight of packaging materials, and the error can usually be controlled within a very small range.

2. Through advanced control technology and valve systems, ensure that the material flows into the packaging bag evenly and stably, further improving the packaging accuracy.

3. Using valve bag packaging, the bag itself has good sealing properties, no additional sealing operation is required, and it can well isolate the outside air.

4. It can be coated internally to provide a more comprehensive protective barrier for the material, further enhance the sealing and moisture resistance, and better maintain the quality and performance of the material.

5. With a high filling speed, it can complete the packaging of a large amount of materials in a short time, improve production efficiency, and meet the needs of large-scale production.

The valve port packaging machine is a highly efficient packaging equipment designed for bulk materials such as powders and granules. It achieves fast and accurate packaging of materials through its unique valve port design and precise metering system, and has good sealing and automatic operation capabilities, effectively improving production efficiency.

With high-precision metering system and intelligent valve control technology, fast and accurate packaging can be achieved. The packaging speed can be adjusted according to material characteristics and packaging specifications.

The valve bag itself has good sealing performance, and combined with the precise filling and sealing operations of the equipment, it can effectively prevent the material from getting wet, oxidized, leaking and contaminating.

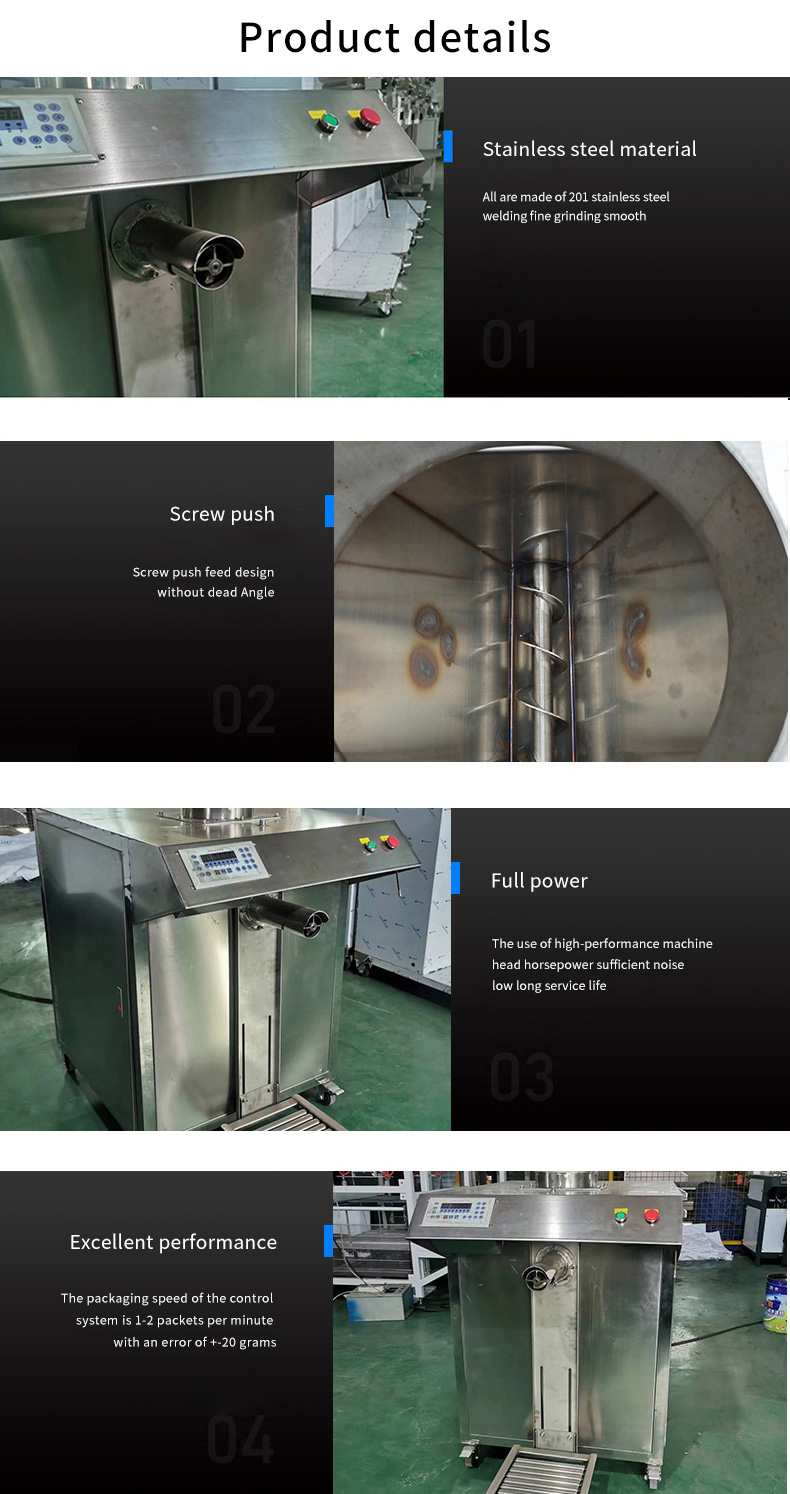

Name: Valve pocket packing machine

Production: The packaging speed is about 1-2 packets per minute, with an error of +-20 grams

Machine size: Length 700MM wide 800MM high 1050MM

Material used: 201 Stainless Steel manufacturing

Motor power: 21.5KW/380V/50HZ

It can be adapted to the packaging of a variety of materials, including various powdered and granular materials. It only needs to adjust the metering method and filling parameters according to the material characteristics.

Equipped with an intuitive human-machine interface, operators can easily set packaging parameters such as packaging weight, filling speed, metering method, etc. through the touch screen without complicated programming and debugging. The equipment has a high degree of automation.

During the material transportation and filling process, advanced sealing technology and dust removal devices are used to effectively reduce dust leakage and flying, and reduce dust pollution to the environment and harm to the health of operators.