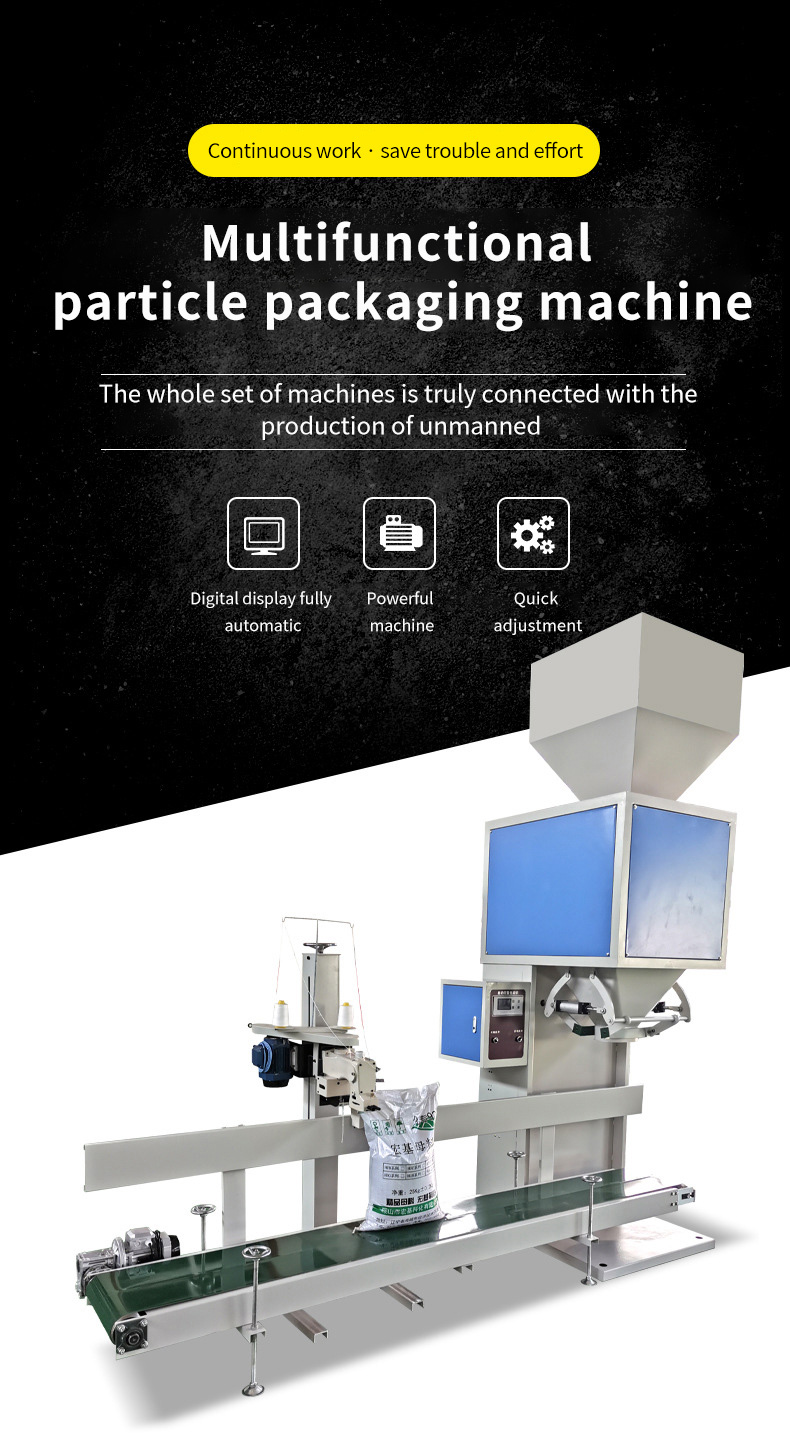

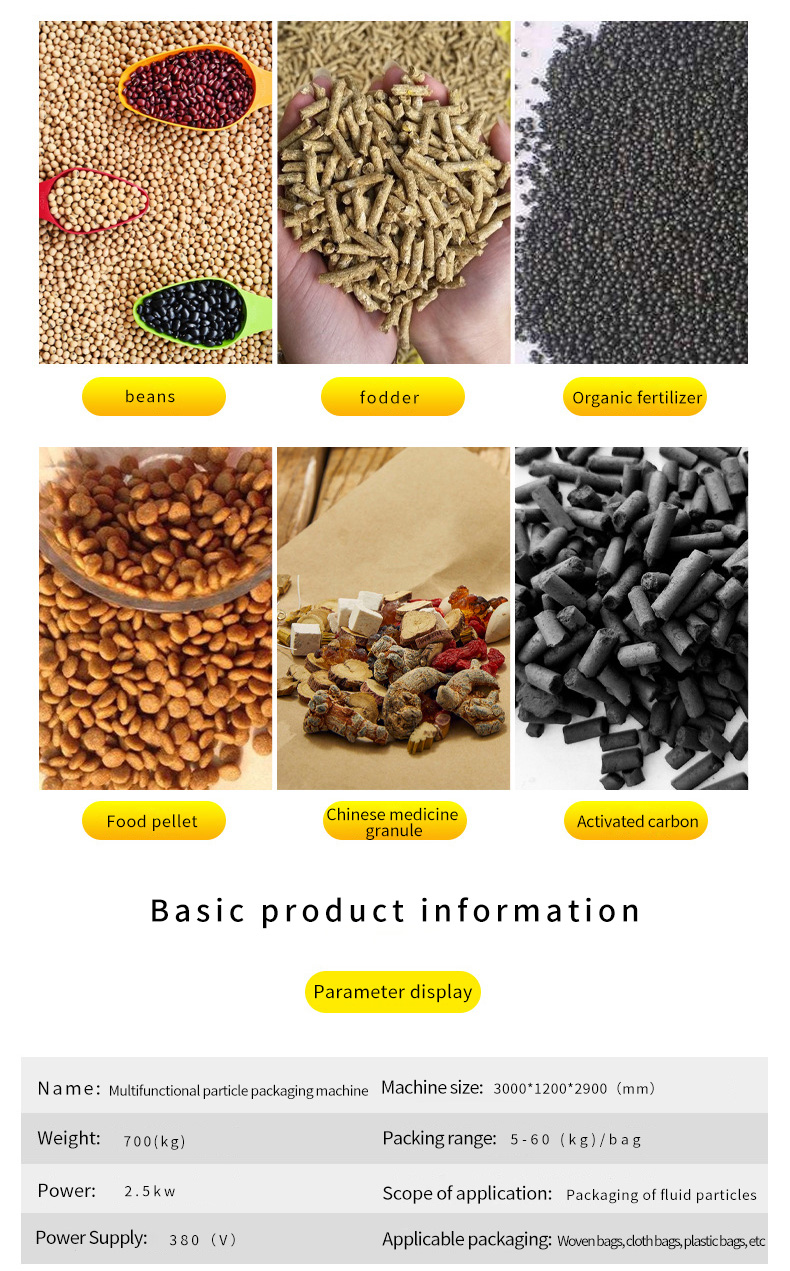

Multifunctional granule packaging machine

1. Flexible application of multiple metering methods: It has multiple metering modes, such as weighing metering, volumetric metering and counting metering. For granular materials of different density, size and value, the appropriate metering method can be selected as needed.

2. Diverse filling and sealing methods: There are rich filling methods, including gravity filling, screw filling, etc. Gravity filling is suitable for particles with good fluidity and can achieve fast filling; screw filling has a good effect on particles with poor fluidity or easy to agglomerate, which can ensure uniform filling.

3. Wide range of packaging form compatibility: It can realize various packaging forms, such as vertical packaging, horizontal packaging, three-side sealing, four-side sealing, back sealing, etc. 4. High-speed packaging capability: It has a high degree of automation and can quickly complete a series of packaging operations such as particle conveying, metering, filling, and sealing.

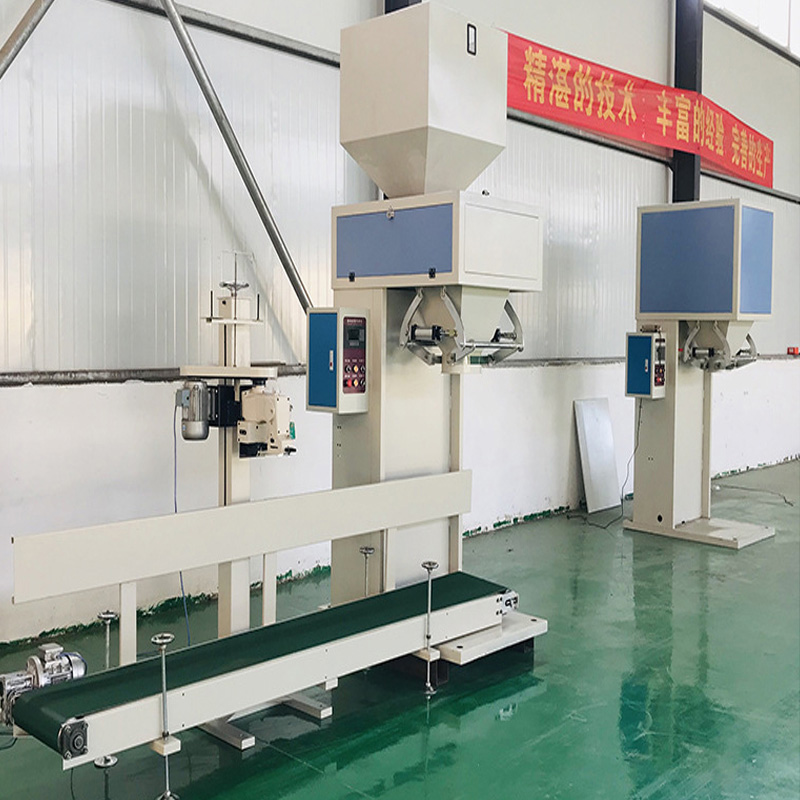

5. Continuous and stable operation: It adopts high-quality mechanical structure and advanced control system, with good stability and reliability.

6. Adapt to different particle characteristics: It can be adjusted according to the size, density, fluidity and other characteristics of the particles.

Multifunctional granule packaging machine is an advanced packaging equipment, specially used for automatic packaging of various granule materials. It integrates multiple functions to meet the needs of different industries, different granule characteristics and diversified packaging. It is widely used in many fields such as food, medicine, chemical industry, electronics, agriculture, etc. It is an ideal choice for efficient, accurate and high-quality packaging of granule products.

It integrates multiple metering methods, filling methods and sealing methods, and can adapt to the characteristics and packaging requirements of different granular materials. Whether it is food, medicine, chemical or other industries, granular products can be packaged with high quality on one device, which improves the versatility and adaptability of the equipment and reduces the cost of enterprises to purchase multiple packaging equipment due to product diversification.

The high degree of automation, fast packaging speed and accurate measurement. The precise measurement system ensures the stable quality of each package of products, avoiding product quality problems and customer complaints caused by measurement errors. The efficient packaging process can complete the packaging tasks of a large number of products in a short time, effectively shorten the delivery cycle, meet the needs of large-scale production, and enhance the competitiveness of enterprises in the market.

It can handle various types of granular materials, including granules of different shapes, sizes, densities, fluidity, viscosity, etc. The processing capacity of special materials, such as hygroscopic, static, and agglomerated granules, is specially designed and configured to ensure the smooth progress of the packaging process, making the equipment widely used in granule packaging in multiple industries.

Parameter display

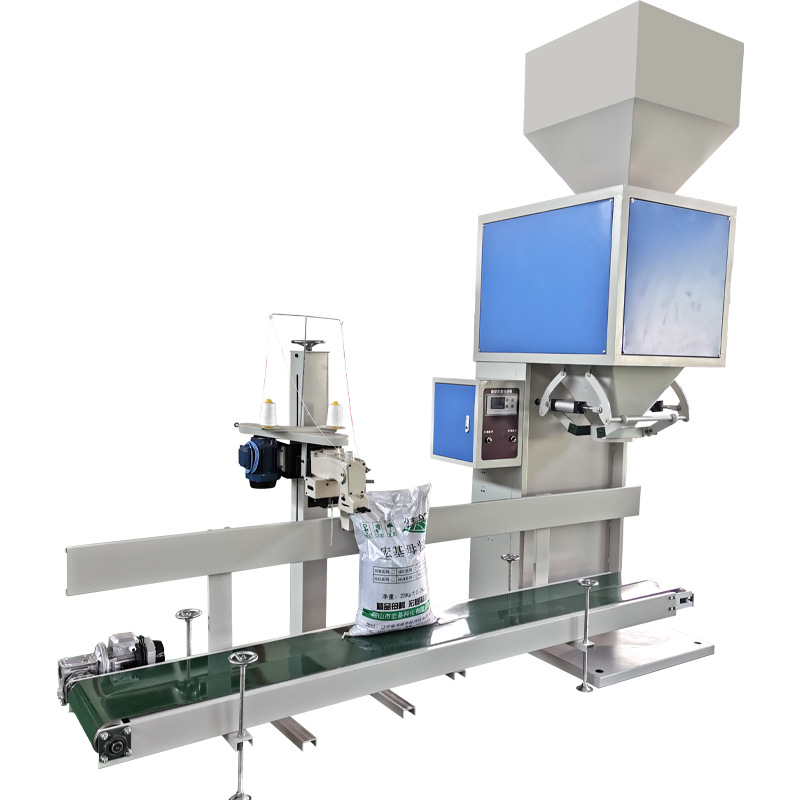

Name: Multifunctional granule packaging machine Machine size: 3000*1200*2900 (mm)

Weight: 700 (kg)

Packing range: 5-60 (kg)/bag

Power: 2.5 kW

Application range: Fluid granule packaging

Power supply: 380 (V)

Applicable packaging: woven bags, cloth bags, plastic bags, etc.

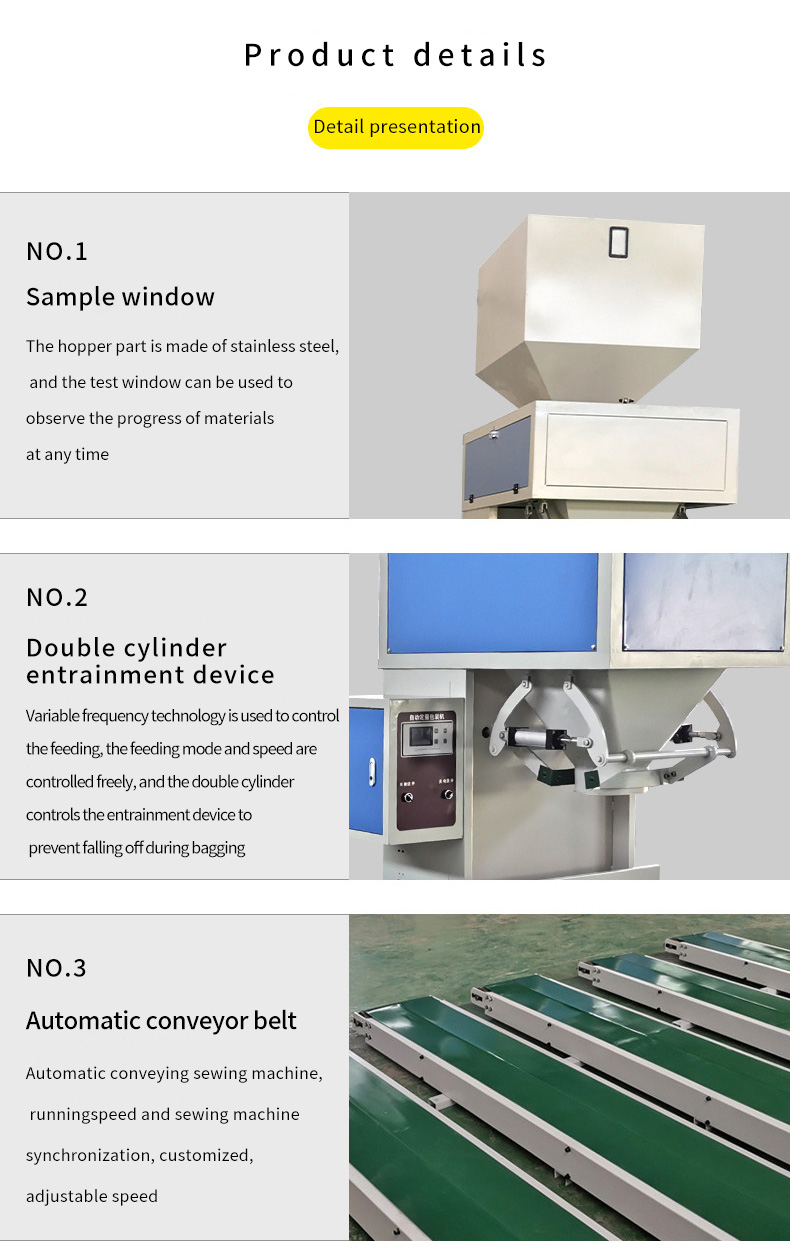

Sample window:

The hopper part is made of stainless steel, and the test window can be used to observe the progress of materials at any time.

Double cylinder entrainment device:

Variable frequency technology is used to control the feeding, the feeding mode and speed are controlled freely, and the double cylinder controls the entrainment device to prevent falling off during bagging.

Automatic conveyor belt:

Automatic conveying sewing machine, runningspeed and sewing machine synchronization, customized, adjustable speed.

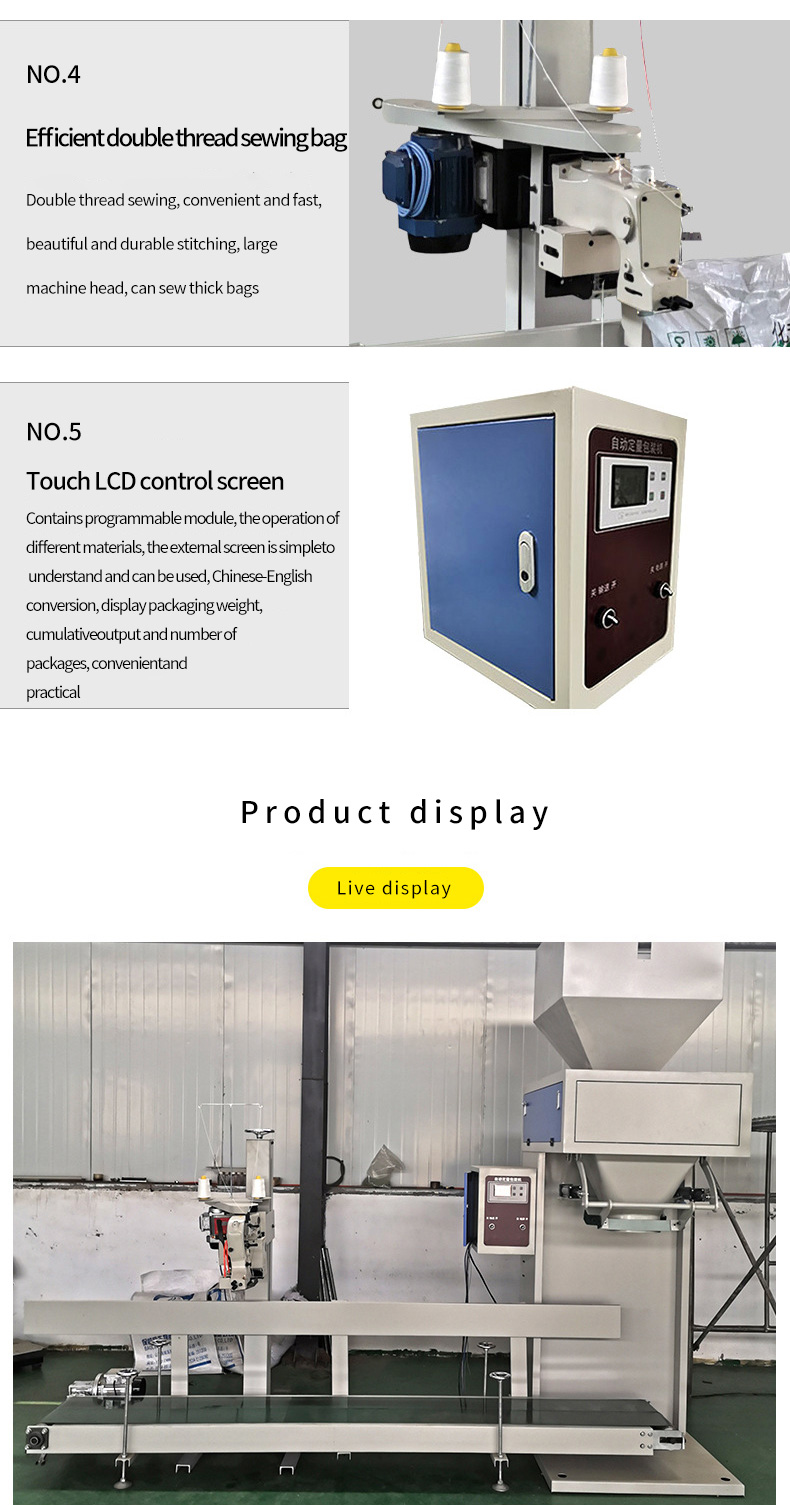

The intuitive human-machine interface allows operators to easily get started without complex professional knowledge and skills. Operations such as parameter setting, equipment monitoring and production data viewing can be completed through the touch screen. The structural design of the equipment is easy to maintain, and key components are easy to disassemble and replace, which reduces maintenance costs and time, and reduces the impact of equipment downtime on production.

Our professional technical team will provide on-site installation services and perform precise installation according to site conditions and equipment requirements to ensure that all equipment components are firmly connected and reasonably laid out.