Fully automatic vertical packaging machine

1. It can automatically complete a series of packaging processes such as material conveying, metering, bag making, filling, sealing, and cutting. It does not require a lot of manual intervention and can complete a large number of packaging tasks in a short time, greatly shortening the production cycle.

2. It reduces the dependence on manual labor and reduces the labor costs caused by manual operation, while also avoiding the impact of human errors on product quality and production progress.

3. Equipped with advanced metering devices, it can accurately measure different types of materials to ensure that the weight or capacity of each bag of products meets the preset standards.

4. It adopts professional sealing technology and devices, such as heat sealing and ultrasonic sealing, which can achieve a firm and tight sealing effect.

5. It is suitable for materials in various forms, including granular, powdery, blocky, liquid, etc. It can be widely used in many industries to meet the diversified packaging needs of different companies.

6. It can make various types of packaging bags, providing companies with a wealth of packaging options to meet the packaging design and market needs of different products.

The fully automatic vertical packaging machine is a high-tech packaging equipment that integrates machinery, electricity, light and gas, and plays an extremely important role in modern industrial production. It is widely used in many industries such as food, medicine, daily chemicals, and chemicals, and can process various forms of materials.

Equipped with advanced metering devices and precise packaging execution systems, it can ensure that the weight of each bag of product is accurate, and the sealing, firmness and appearance quality of the packaging are good. The metering error can be controlled within a very small range.

It can be adapted to the packaging of materials of various types, forms and specifications. Whether it is granular, powdery, block or liquid materials, efficient and high-quality packaging can be achieved on this equipment.

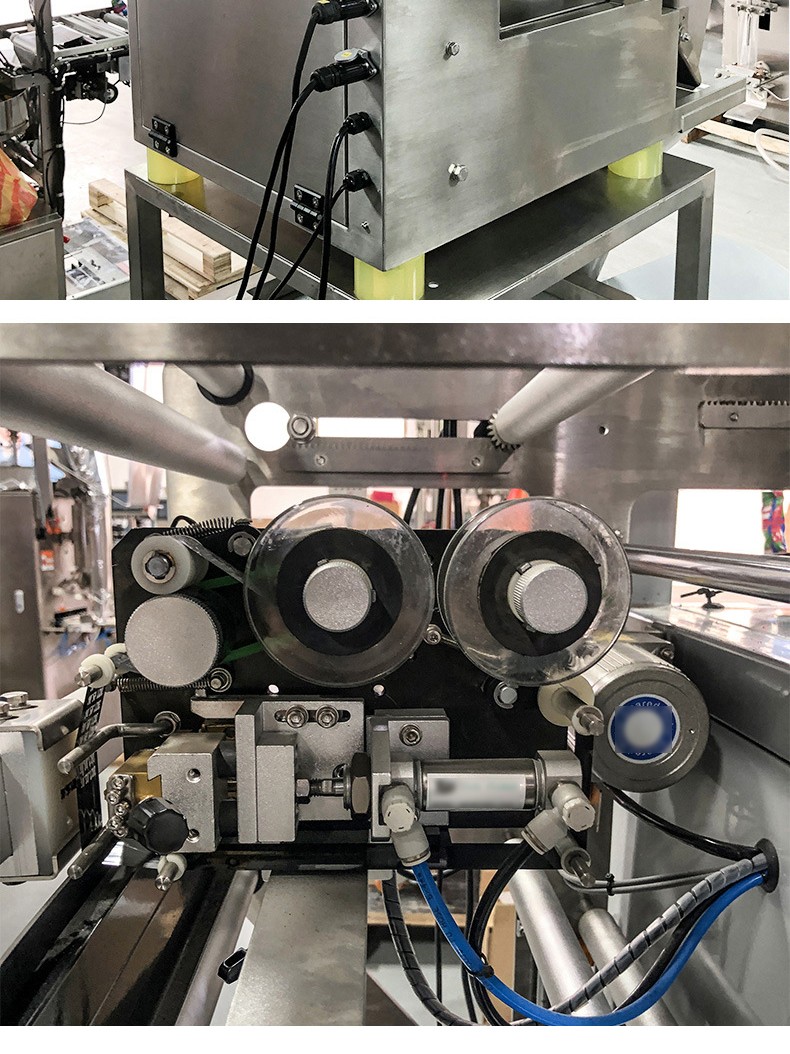

The use of high-quality mechanical parts, electrical components and advanced manufacturing technology ensures that the equipment maintains stable and reliable performance during long-term continuous operation. Precise coordination and optimized design between various components.

During the design and manufacturing process, we focus on the application of energy-saving and environmental protection concepts, and use energy-saving motors, optimized power systems and intelligent energy management technologies to reduce the energy consumption of equipment.

Application areas:

Food industry: It can ensure the hygiene and safety of food and the quality of packaging, extend the shelf life of food, and improve the production efficiency of food packaging.

Pharmaceutical industry: It can accurately control the metering and packaging process of drugs, ensure the dosage of drugs is accurate, and meet the GMP standards for drug production.

Daily chemical industry: It can produce exquisite packaging bags according to the characteristics of products and market demand, and improve the attractiveness and added value of products.

Chemical industry: The fully automatic vertical packaging machine can adapt to the characteristics of chemical materials, achieve efficient and stable packaging, and prevent material leakage and pollution.