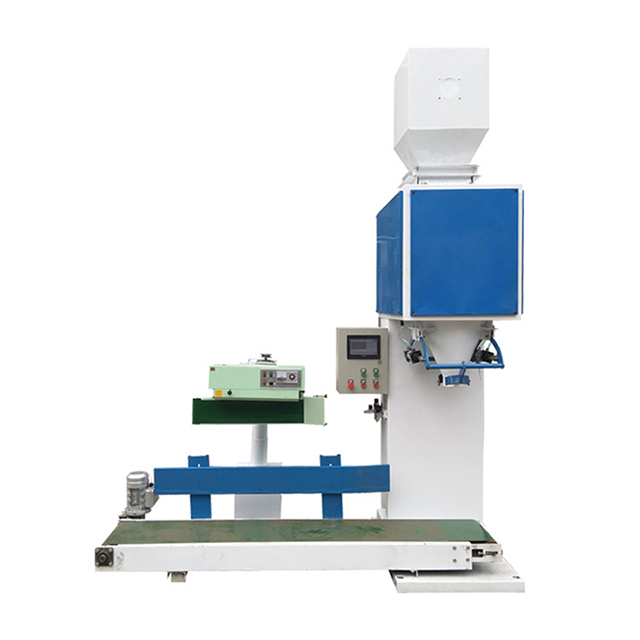

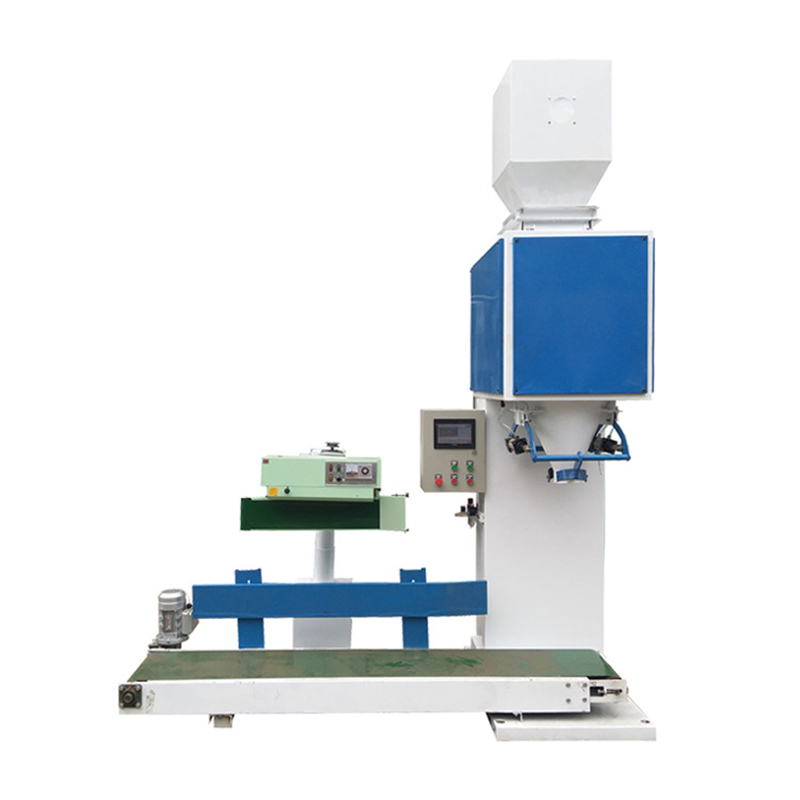

Automatic quantitative weighing packaging machine

1. High-precision measurement: The use of advanced weighing sensors and control systems can achieve high-precision material quantification and ensure that the weight error is within a very small range.

2. Efficient production capacity: With a high degree of automation, it can continuously and quickly complete a series of operations such as material supply, weighing, packaging, and sealing, greatly improving production efficiency.

3. Strong material adaptability: It can handle materials of various forms and properties. By adjusting the relevant parameters of the equipment or replacing some accessories, it can meet the packaging requirements of different materials.

4. Reduce human errors: Reduce human intervention and avoid the uncertainty and errors caused by manual operation.

5. Good equipment stability: The structure is reasonably designed, using high-quality materials and components, and is durable, stable and reliable in performance.

6. Data traceability: The automatic quantitative weighing and packaging machine also has data recording and storage functions, which can record the relevant data of each packaging.

Automatic Quantitative Weighing Packaging Machine is a modern mechanical equipment that integrates automatic control, precise weighing and efficient packaging functions. It aims to provide accurate, fast and stable product packaging solutions for various industries. It can meet the quantitative packaging needs of materials of different forms and specifications, effectively improve production efficiency, ensure product quality and enhance the market competitiveness of enterprises.

Material conveying: The material to be packaged is delivered to the feeding port of the packaging machine through a suitable conveying method. Common conveying methods include vibration feeding, screw conveying, belt conveying, etc., which are selected according to the shape and characteristics of the material. For example, granular materials are mostly fed by vibration or screw conveying, and the thrust generated by vibration or screw rotation is used to make the material enter the weighing area evenly and stably.

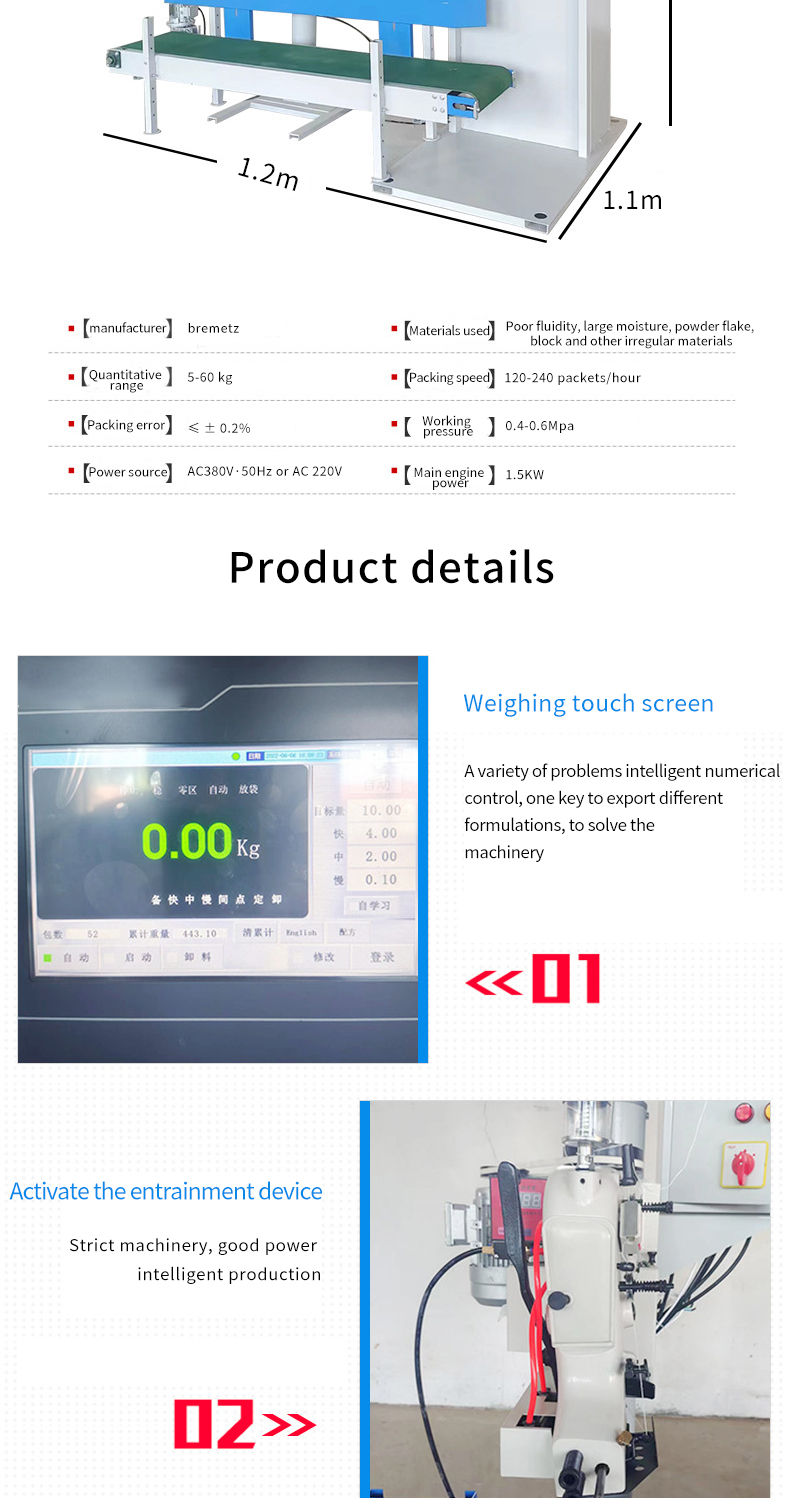

manufacturer:bremetz

Quantitative range:5-60 kg

Packing error:≤ ± 0.2%

Materials used:Poor fluidity, large moisture, powder flake, block and other irregular materials.

Packing speed:120-240 packets/hour

Working:10.4-0.6Mpa pressure

Power source:AC380V-50Hz or AC 220V

Main engine power:1.5KW

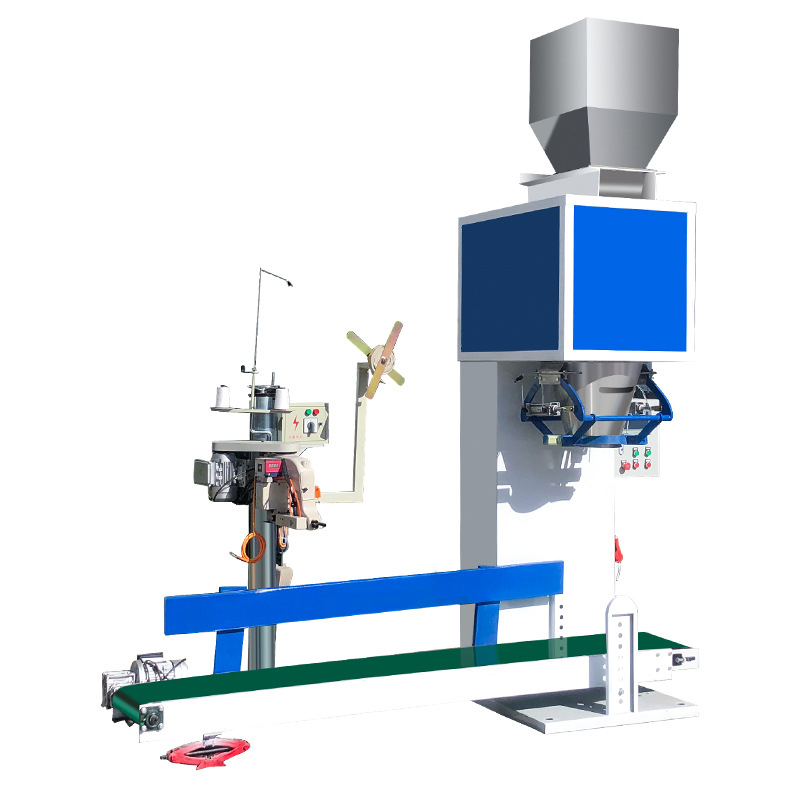

A variety of problems intelligent numerical control, one key to export different formulations, to solve the machinery.

Activate the entrainment device,Strict machinery, good power intelligent production.

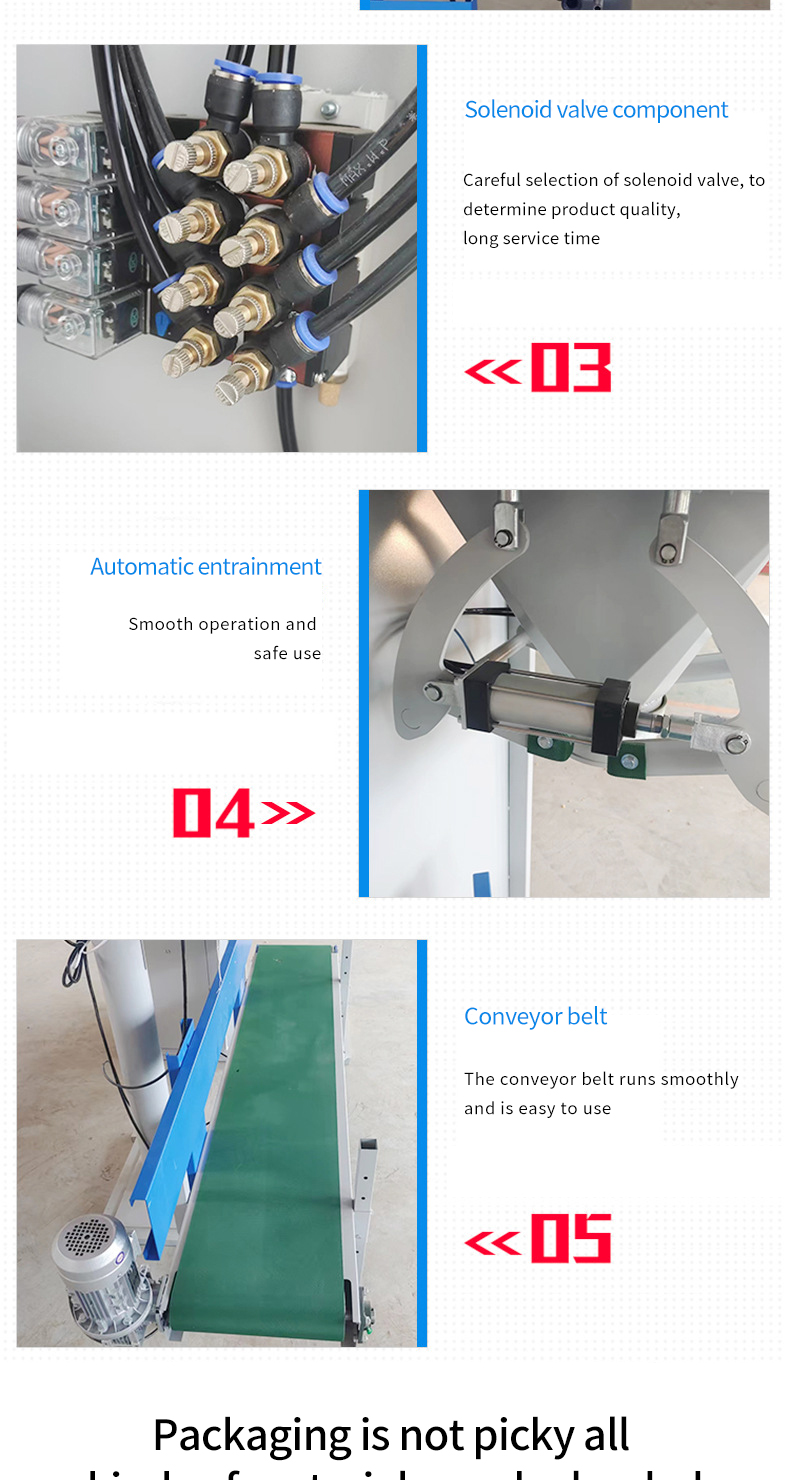

Solenoid valve component,Careful selection of solenoid valve, to determine product quality, long service time.

Automatic entrainment,Smooth operation and safe use.

Conveyor belt,The conveyor belt runs smoothly and is easy to use.

Applicable industries:

Food industry: used to package rice, flour, various grains, etc., to meet the accurate measurement requirements of food and packaging requirements such as hygiene and preservation, and to ensure the quality and safety of food.

Pharmaceutical industry: strictly follow the pharmaceutical production quality management specifications, accurately quantitatively package medicines, health products, etc., to ensure that the dosage of each medicine is accurate.

Chemical industry: suitable for packaging various chemical raw materials, chemical reagents, etc., and can cope with materials of different chemical properties and complex packaging environments.

Daily chemical industry: can package daily chemical products such as washing powder, laundry detergent, shampoo, etc., to achieve exquisite packaging of products and improve the market competitiveness of products.

Agricultural industry: used to package agricultural production materials such as seeds, feed, pesticides, etc., to ensure accurate measurement of seeds, so that farmers can sow according to the correct dosage.

A professional technical team will provide installation services, perform precise installation according to site conditions and equipment requirements, and ensure that all equipment components are firmly connected and reasonably laid out. After installation, comprehensive commissioning will be carried out.

We have established a complete after-sales maintenance network and equipped it with professional maintenance personnel. After receiving a fault report from the user, we can respond quickly and rush to the site for repair in time.