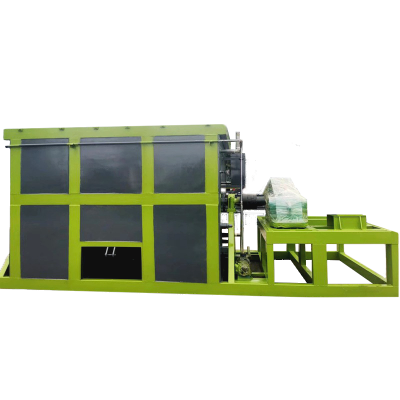

Multifunctional roulette turning machine

1. The unique wheel structure can fully flip the material in a short time when rotating at high speed, greatly improving the working efficiency.

2. The flipping blades on the wheel are carefully designed, evenly distributed and at a reasonable angle, which can ensure that the material can be evenly flipped in all directions.

3. In addition to the basic flipping function, it can also be equipped with various functional modules such as material crushing, mixing, and conveying according to actual needs.

4. By adjusting parameters such as the wheel speed and the flipping blade angle, the characteristics and processing requirements of different materials can be met.

5. Equipped with an intelligent control system, the operator only needs to set the parameters on the console, and the equipment can automatically complete the flipping operation.

The unique wheel structure and high-speed rotation design enable the material to be fully turned over in a short time. Compared with traditional turning equipment, the working efficiency can be increased by 30% - 50%.

It integrates multiple functions such as turning, crushing, mixing and conveying. One device can complete multiple operations, reducing equipment purchase costs and floor space, and improving production efficiency.

The intelligent control system realizes the precise setting and real-time monitoring of equipment operating parameters, ensuring the stability and consistency of the material handling process and improving product quality.

It has good adaptability to various organic materials such as livestock and poultry manure, sludge, crop straw, domestic garbage, etc., and can be used in many fields such as organic fertilizer production, sewage treatment, and biomass energy development.

With modular design, each functional module is easy to disassemble and replace. Key components are made of high-quality materials with strong wear resistance and corrosion resistance, reducing the number and cost of equipment maintenance.