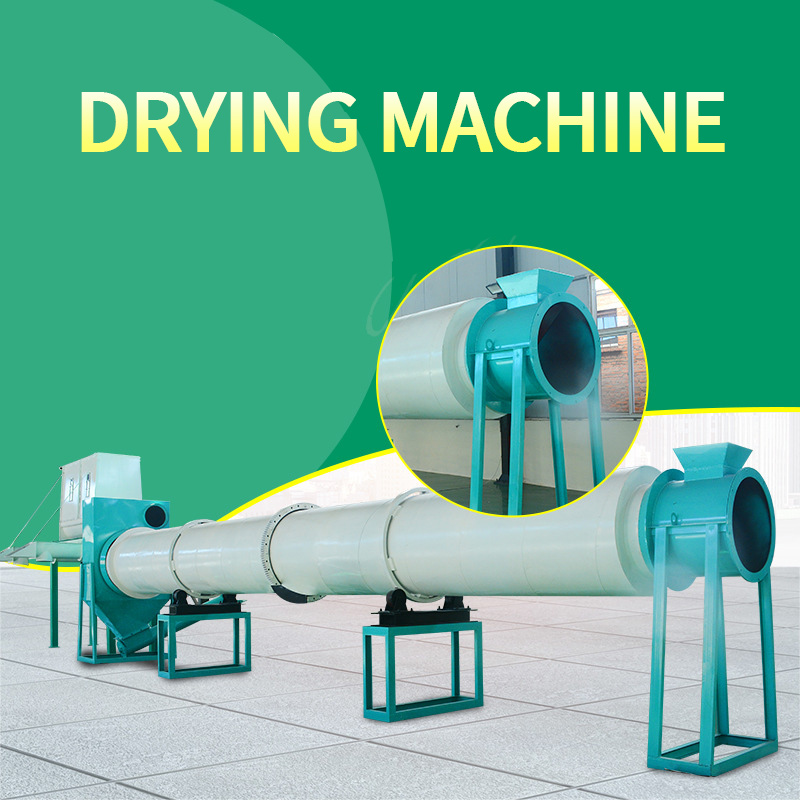

Organic fertilizer drying machine

1. The use of advanced heat exchange technology can greatly improve the heat utilization rate and accelerate the evaporation rate of water.

2. Equipped with an intelligent temperature control system, the drying temperature can be accurately adjusted according to the characteristics of different organic fertilizers.

3. It can handle organic fertilizer raw materials of various forms and sources and can effectively dry them.

4. The design focuses on energy conservation and emission reduction, and the waste heat generated during the drying process is recycled and reused to reduce energy consumption and production costs.

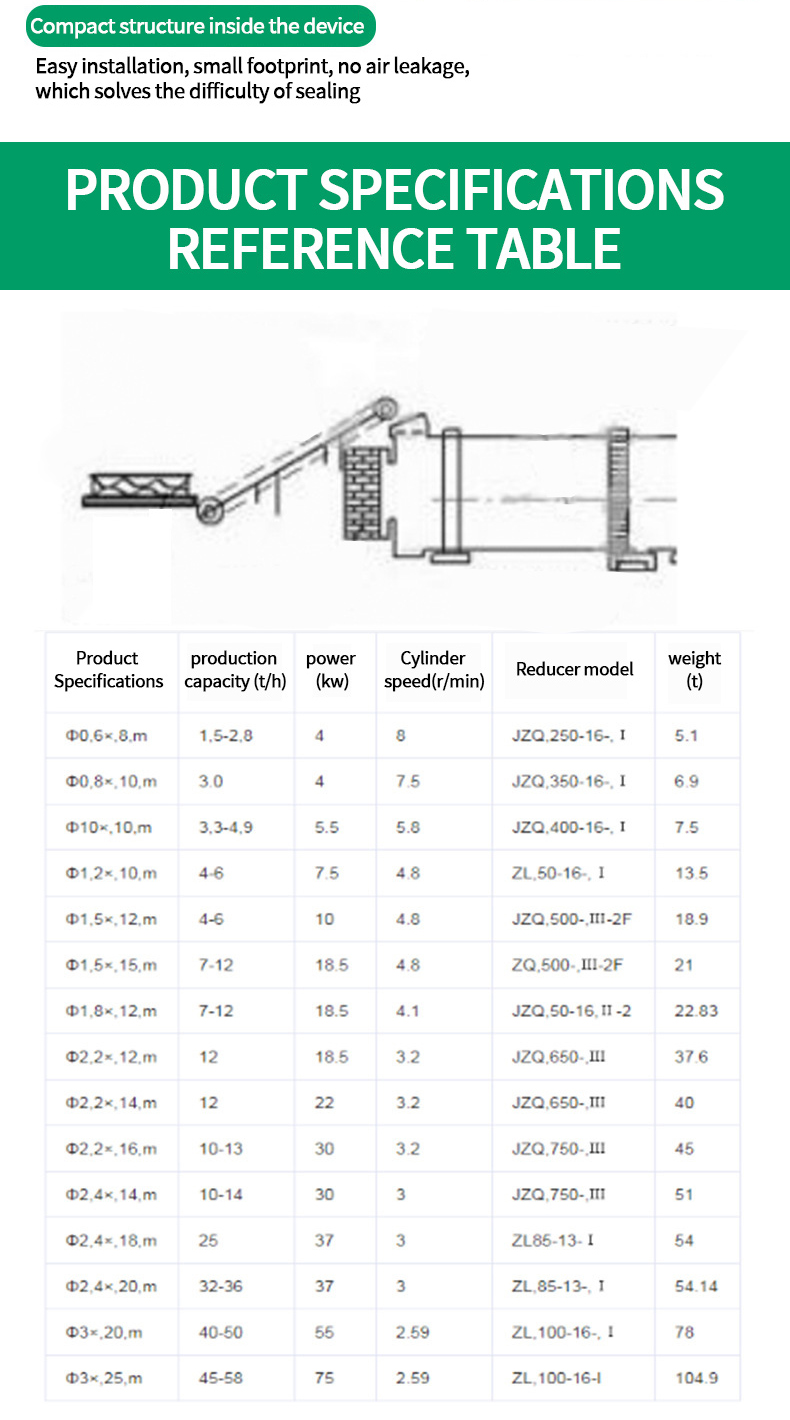

5. The structural design is reasonable, and the key components are made of high-quality materials with good wear resistance and corrosion resistance.

During the drying process, the intelligent control system can accurately adjust the hot air temperature, flow rate and material residence time to ensure the stability and consistency of the drying effect.

The unique structural design and efficient heat exchange method enable the material to be dried quickly in a short time, with strong production capacity, which can meet the needs of large-scale production.

Precise temperature control and uniform heat transfer ensure that the material is dried evenly and has a stable moisture content, effectively avoiding problems such as fertilizer agglomeration and deterioration, and improving product quality.

Energy-saving heating equipment and waste heat recovery technology are used to reduce energy consumption. At the same time, the perfect tail gas treatment system reduces environmental pollution and meets national environmental protection requirements.

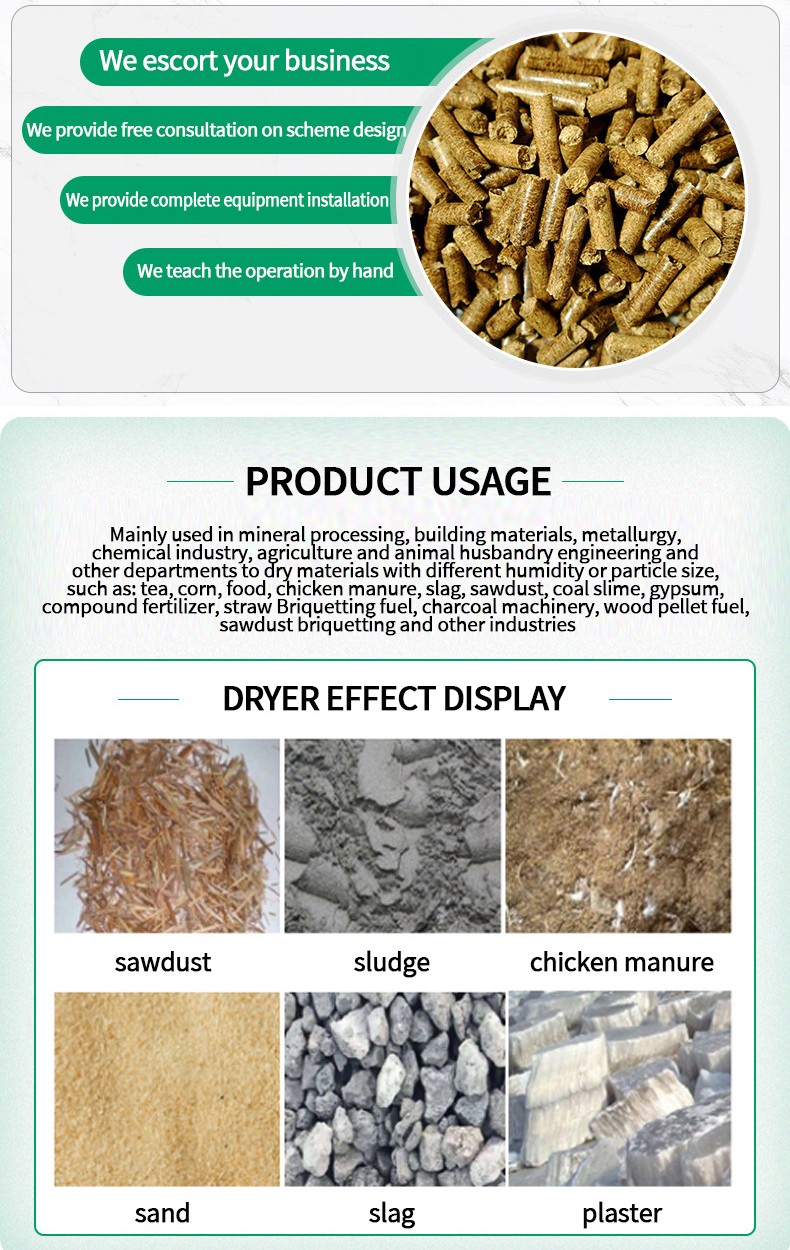

It can meet the drying requirements of various organic fertilizer raw materials, such as livestock and poultry manure, straw, sludge, etc. By adjusting the equipment parameters, it can meet the drying characteristics of different materials.

The intelligent control system has an easy-to-understand operation interface. Operators can master the operation of the equipment after simple training, reducing labor intensity and labor costs.

It is widely used in various organic fertilizer production enterprises, including fertilizer plants affiliated with farms that use livestock and poultry breeding waste as raw materials, and bio-organic fertilizer production enterprises that use crop straw for comprehensive utilization.