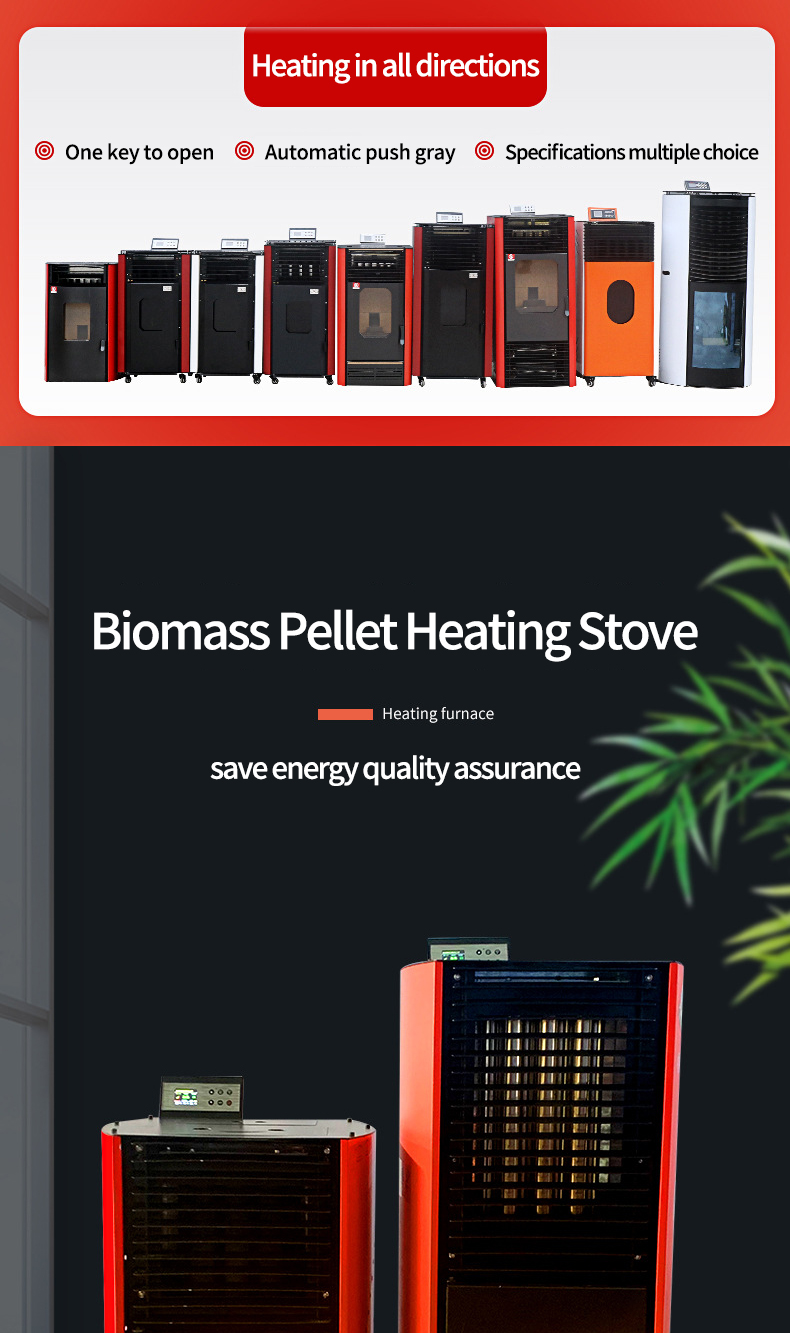

Biomass pellet heater

1. During the combustion process, biomass pellet heaters produce relatively few pollutants. This helps reduce air pollution.

2. Biomass pellets have uniform shape and size, and are dense in texture, which can achieve full and efficient combustion in specially designed heaters.

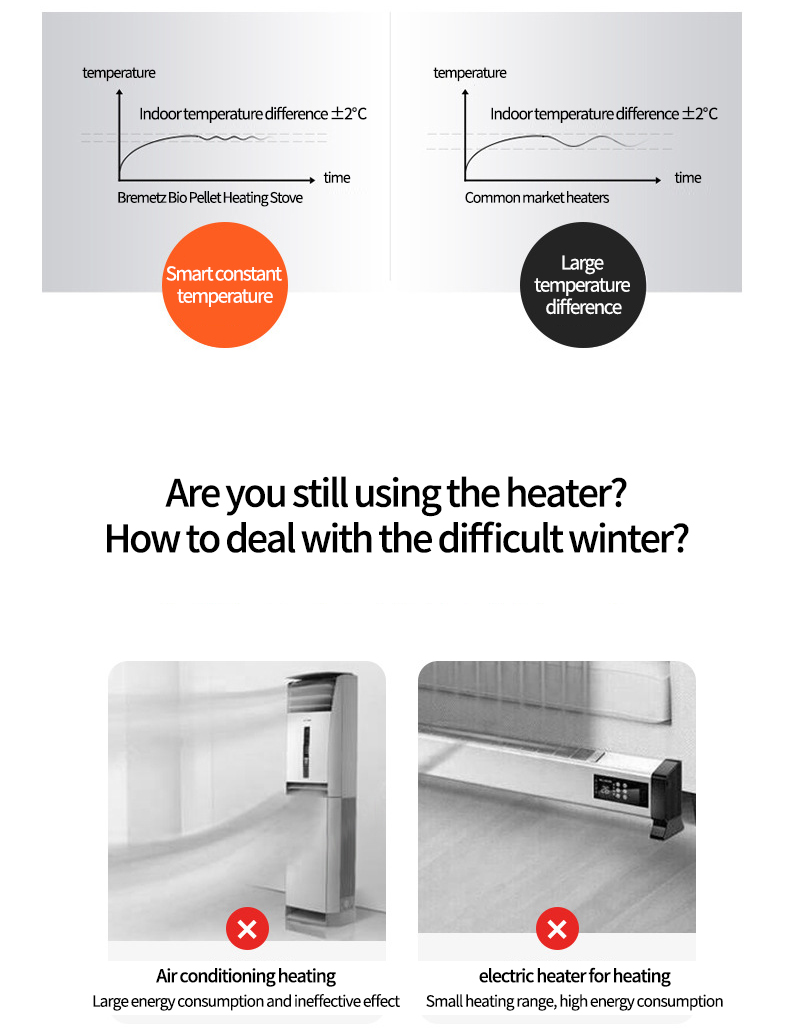

3. Biomass pellet heaters are equipped with advanced combustion control systems, which can automatically adjust the combustion speed and feed rate according to the set temperature requirements.

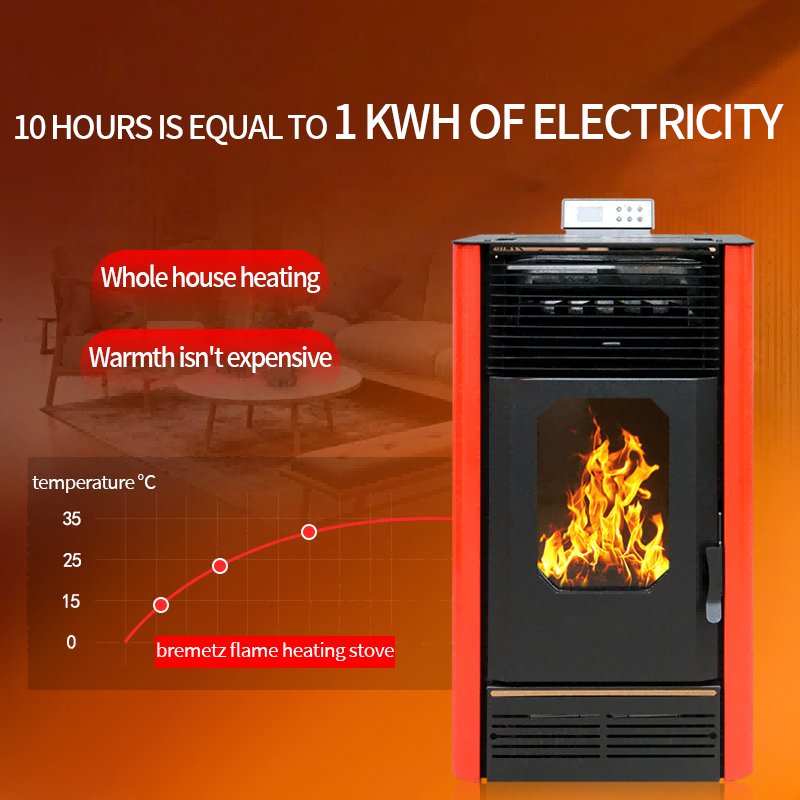

4. It can achieve temperature rise in a shorter time and quickly reach the set temperature, saving users waiting time.

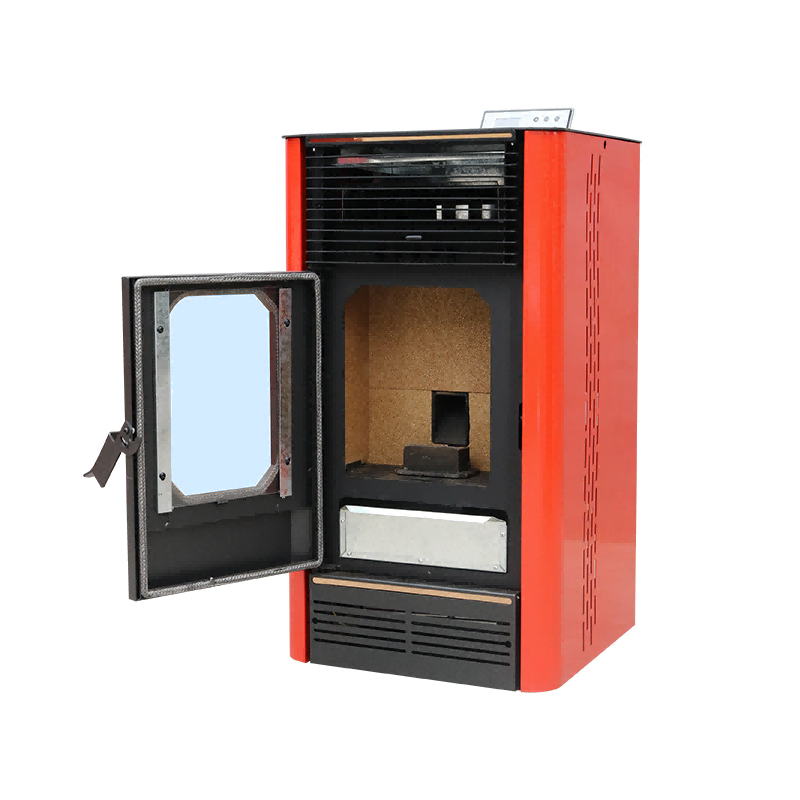

5. The structure of the biomass pellet heater is relatively simple, maintenance is relatively convenient, and it is not easy to have complex failures.

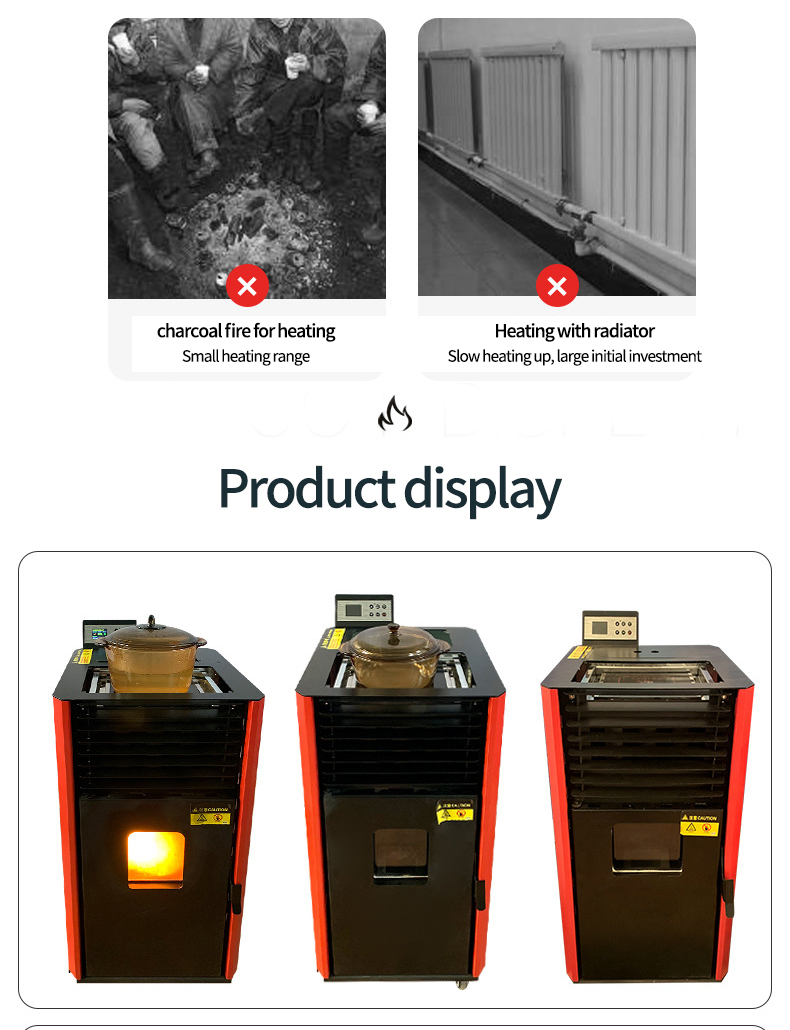

Biomass pellet heaters use biomass pellets as fuel, such as pellets made by compression of sawdust, straw, rice husk, etc. These pellets are fed into the combustion chamber and fully burned in a high temperature environment to release heat energy.

The raw materials are renewable, and carbon dioxide emissions are close to zero during combustion. Pollutant emissions are far lower than traditional fossil fuels, with high combustion efficiency and significant energy-saving effects.

The cost of biomass pellets is lower than that of natural gas, fuel oil, etc. They are easy to maintain, reduce repair costs, and are also subsidized by the government in some areas.

The combustion is stable, the heating is continuous, and it can quickly reach the set temperature to meet the heating needs of different places.

Intelligent control system, simple operation, remote monitoring, convenient for users.

Provide a warm and comfortable indoor environment for families, replacing traditional coal-fired and gas-fired boilers.

It can be used in industrial drying, process heating and other links to reduce enterprise energy costs.