Corn flakes manufacturing equipment helps enterprises transform efficiently

Crisp Bobo Food Company is a traditional grain processing company with a 20-year history. With the rise of the trend of healthy food consumption, the urgency of producing instant grain products such as corn flakes has increased. However, the original simple equipment and scattered processes cannot meet the needs of high-quality and large-scale production.

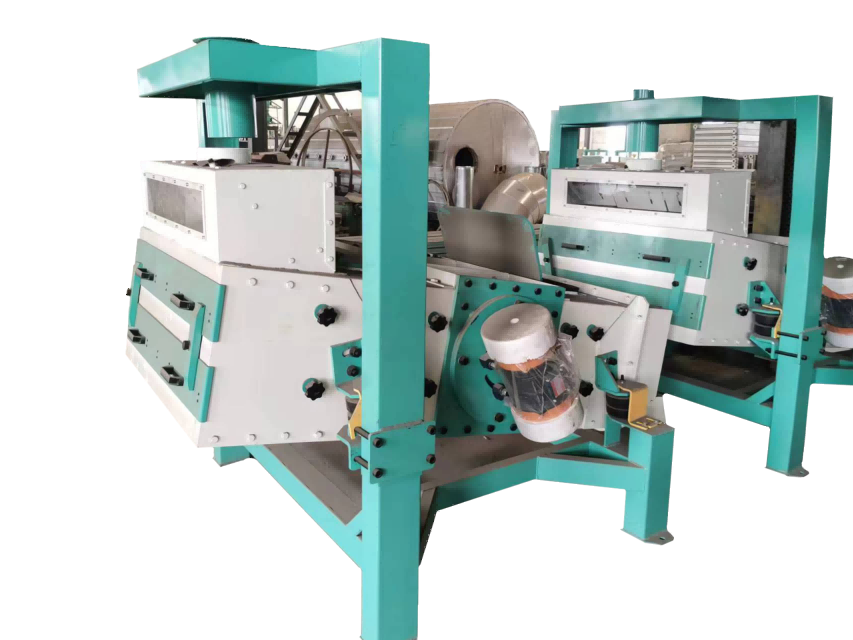

After multiple inspections and careful evaluations, the company introduced a complete set of Corn flakes manufacturing equipment production lines, covering the entire process from raw material pretreatment to packaging, and innovating the production pattern.

Efficient integrated process: The units of the production line are seamlessly connected. After the "triple purification" of the raw materials by the vibrating screen, stone remover, and magnetic separator, they are directly put into the mill for precise grinding, and then mixed uniformly with the pre-mixed nutrients in the mixer, and then instantly expanded by the twin-screw extruder, and the tablet press is formed with one button.

Intelligent and precise control: Equipped with a PLC integrated touch screen, it can preset and store more than 50 corn flake process formulas, and adjust the temperature, pressure and other parameters of each link in real time according to product requirements to ensure that the product has a golden and uniform color, precise thickness, and a crisp and stable taste.

Nutritional retention innovation: By adopting low-temperature, short-time extrusion puffing and gentle baking technology, combined with nutritional fortification and addition, the dietary fiber retention rate in corn flakes exceeds 80%, and the content of nutrients such as B vitamins is increased by 50% compared with the old process.