High-precision column palletizer

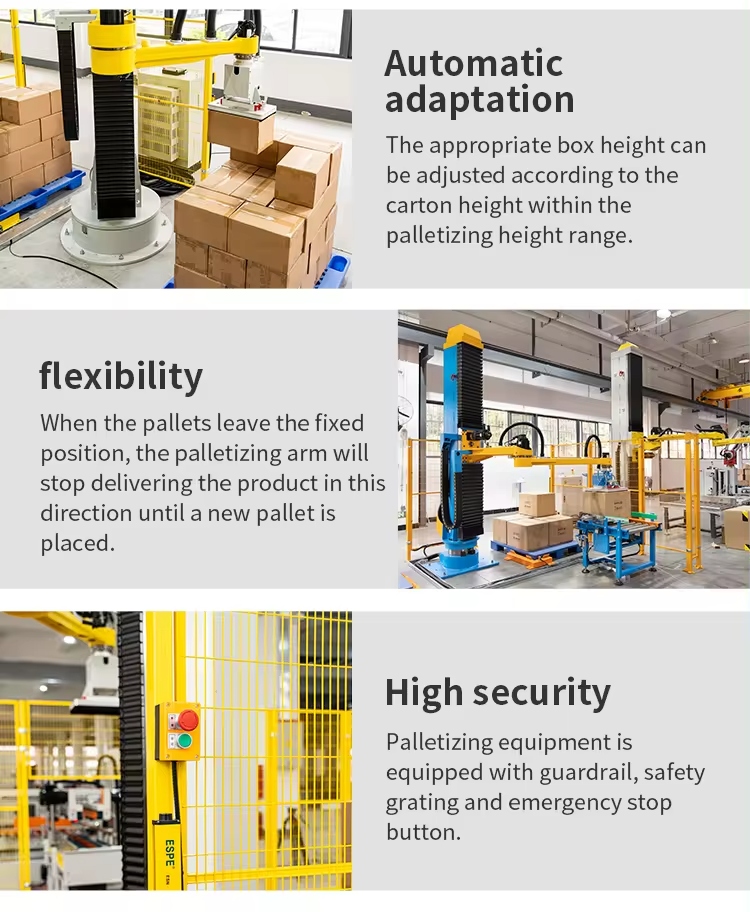

1. The use of advanced control systems and high-precision sensors can accurately control the stacking position and ensure that the goods are neatly stacked on the pallet.

2. During the transportation and positioning of the pallet, it has a precise positioning function and can accurately deliver the pallet to the stacking position.

3. It is usually made of high-strength steel, and the column structure is reasonably designed to withstand large loads and impact forces.

4. The column structure is relatively compact and occupies less space. It can be flexibly installed and used in limited production workshops or warehouse spaces.

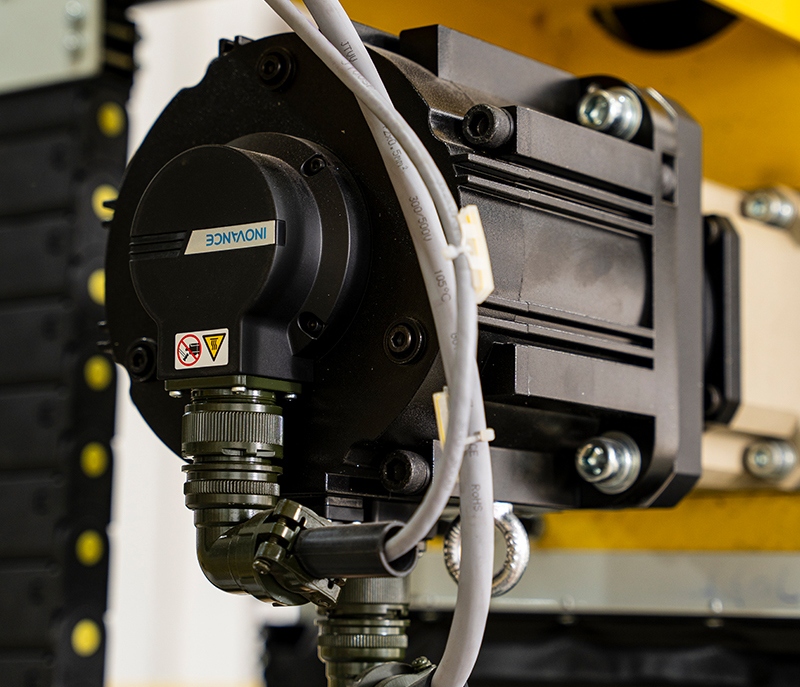

5. Equipped with a fast-response servo motor and an efficient transmission system, it can achieve fast grabbing, handling and stacking actions, greatly improving the speed of stacking.

This high-precision column palletizer is a modern logistics packaging equipment that integrates advanced mechanical manufacturing, electronic control, and intelligent algorithms. It is designed to meet the needs of various industries for high-precision, high-efficiency, and high-stability product palletizing.

Equipped with advanced laser navigation, visual recognition, encoders and other high-precision positioning technologies, it can accurately control the position of the cargo platform in three-dimensional space.

The gripping device adopts high-precision motion control technology and flexible gripping design, which can be adaptively adjusted according to the characteristics of different products.

The equipment maintains stable performance during high-speed operation. Through advanced shock absorption and balancing technology, vibration and shaking are effectively reduced to ensure that the accuracy and stability of palletizing are not affected.

Equipped with advanced PLC and human-machine interaction interface, it has intelligent operation and control functions. Operators can start, stop, set parameters, diagnose faults, monitor operating status, etc. through the intuitive and concise touch screen interface.

Supports a variety of preset palletizing modes and pallet type programming. Users can easily set different parameters such as the number of palletizing layers, the arrangement of each layer, and the product spacing in the control system according to actual needs and product characteristics.

The equipment is also equipped with an automatic diagnosis and early warning system, which can monitor the operating status and key parameters of each component in real time, such as motor temperature, current, and wear of transmission components.