Screw feeding machine

1. High conveying efficiency: The spiral blades rotate continuously in the tube, which can push the material forward uninterruptedly and realize continuous material conveying.

2. Adjustable conveying speed: By adjusting the speed of the spiral shaft, the material conveying speed can be easily changed to meet the needs of different production processes. Whether it is necessary to convey materials quickly and in large quantities, or to accurately control the conveying volume, it can be flexibly responded to.

3. Accurate metering: In the process of conveying materials, the number of rotations of the spiral blades of the spiral feeder has a relatively accurate correspondence with the amount of material conveyed. Combined with advanced sensors and control systems, the feeding amount can be accurately measured and controlled to meet the production process with high requirements for material metering accuracy.

4. Good sealing: The gap between the spiral blades of the spiral feeder and the material trough is small, and the entire conveying process is carried out in a closed pipe or trough, which can effectively prevent material leakage.

5. Adapt to different working environments: The spiral feeder can be installed horizontally, tilted or vertically according to the actual situation of the production site, which can meet the material conveying needs in different working scenarios.

6. Low noise operation: During the operation of the screw feeder, the friction and collision between the spiral blades and the material are relatively small, and the noise generated is low.

Screw feeder is a kind of material conveying equipment widely used in the industrial field. It is based on the principle of spiral rotation to achieve stable and accurate conveying of various materials. Through continuous or quantitative feeding, it provides a stable material supply for subsequent links in the production process, playing a key role in many industries such as chemical, food, mining, building materials, etc.

Six advantages:

Support customization,copper core motor,thickened material,factory Outlet,work efficiently,Has many uses

Product parameters.

name: Screw feeder

Material:304/201 stainless steel/galvanized carbon steel

Hopper Size: Conventional 60*60CMcan be customized Diameter: 89-110-140-160-220-273-325(MM)

power: 0.75~15KW

Yield: 10KG~30T/hour (can be customized)

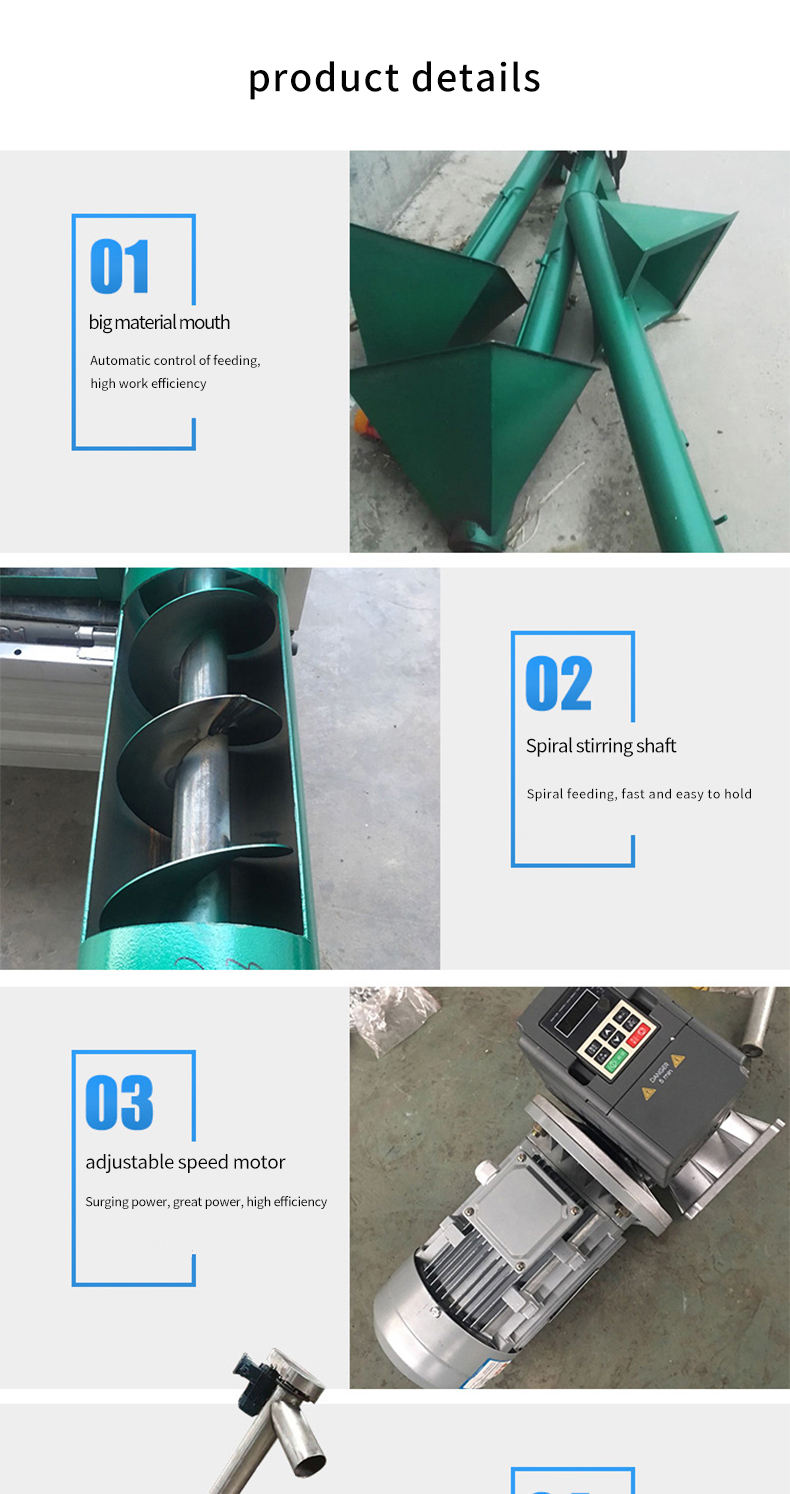

Product details:

Big material mouth,Automatic control of feeding, high work efficiency.

Spiral stirring shaft,Spiral feeding, fast and easy to hold.

Adjustable speed motor,Surging power, great power, high efficiency.

Food grade stainless steel,Excellent material, strong stability and no shaking.

The operation of the equipment is relatively simple. The basic control of the feeding process can be achieved by controlling the start, stop and speed of the motor. Operators can master the operation method after simple training. At the same time, the spiral feeder has a simple structure and easy maintenance and replacement of parts. Daily maintenance work mainly includes checking the wear of the spiral blades, lubricating the bearings, cleaning the debris in the trough, etc. The maintenance cost is low, which helps to reduce the operating cost of the enterprise.

Since the conveying process of the screw feeder is carried out in a closed trough and the gap between the spiral blades and the trough is small, the leakage of materials and the mixing of external impurities are effectively prevented. This is especially important for the conveying of volatile, toxic, corrosive materials or materials with high purity requirements. For example, when conveying easily contaminated materials such as milk powder in the food industry, the hygiene and quality of the products can be guaranteed; when conveying toxic gas or liquid raw materials in the chemical industry, the safety of the production environment is guaranteed.

We have a professional after-sales maintenance team that can respond promptly to user fault reports. Our maintenance personnel have rich maintenance experience and professional knowledge and can quickly diagnose and solve equipment problems.