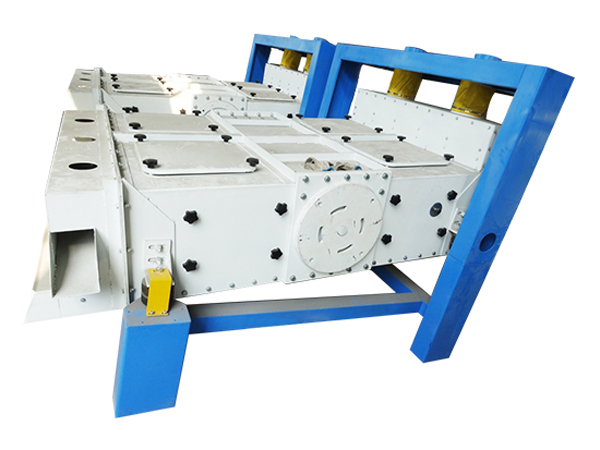

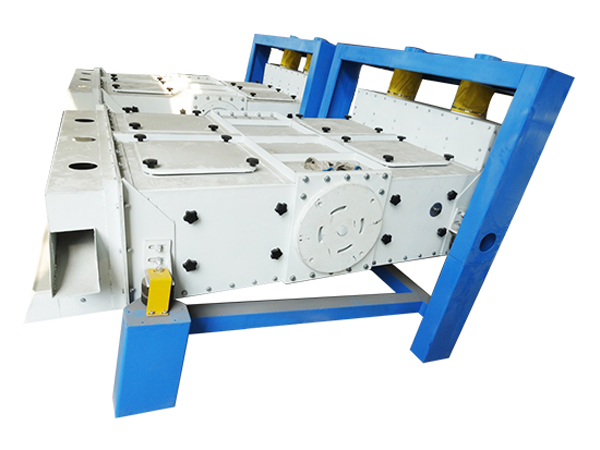

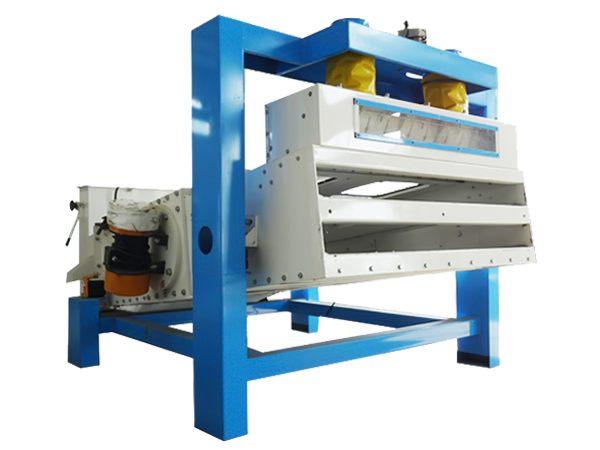

Automatic vibrating screen

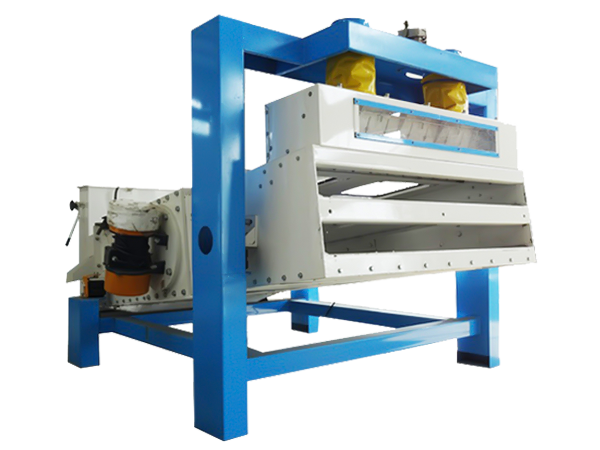

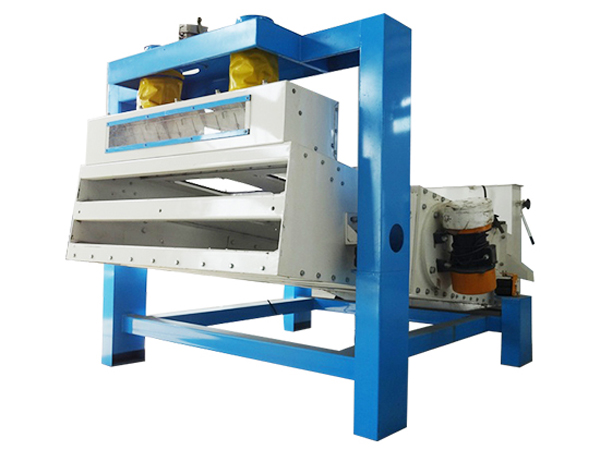

1. Equipped with a high-performance vibration motor, it can generate high-frequency vibration, greatly improving the screening speed.

2. It is usually designed as a multi-layer structure, with different apertures of each layer of screen, which can simultaneously achieve multi-level screening of materials.

3. According to the characteristics and screening requirements of different materials, the appropriate screen material, aperture and weaving method can be selected.

4. From the automatic feeding and screening process of materials to the automatic discharge of finished products and waste materials, the entire process can be automated.

5. The fuselage is made of high-strength steel, and after special welding and heat treatment processes, it has good rigidity and fatigue resistance.

Automatic vibrating screen is a screening device that uses a vibrating motor to generate exciting force to force the material to move on the screen surface, thereby separating materials of different particle sizes. It integrates automatic feeding, screening and discharging, greatly improving production efficiency and reducing manual intervention.

It has the functions of automatic feeding, screening and discharging, and can be seamlessly connected with other production line equipment to achieve fully automated production, improve production efficiency and reduce labor costs.

By precisely controlling the vibration parameters and selecting the appropriate screen, materials of different particle sizes can be accurately separated, and the screening accuracy can reach more than 95%, meeting the needs of industries with strict requirements on product quality.

It can be used in mining, metallurgy, chemical industry, building materials, food, medicine and other industries to screen, grade and remove impurities of various particles, powders and slurry materials.

The design structure is reasonable, and each component is easy to disassemble and replace, which is convenient for daily maintenance and upkeep. At the same time, the equipment is equipped with an intelligent fault diagnosis system, which can detect and solve faults in time and reduce downtime.