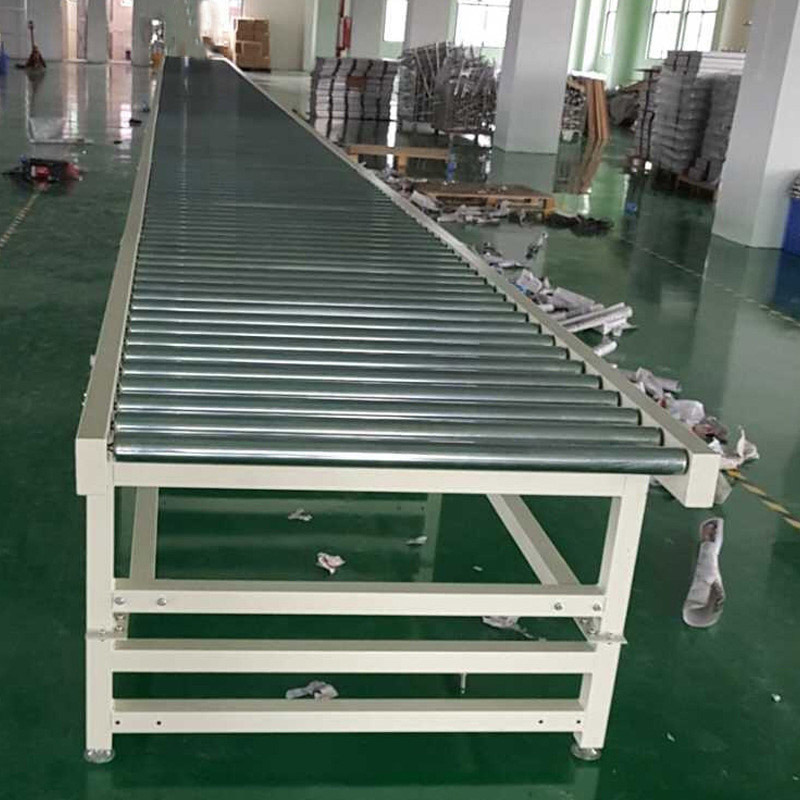

Roller conveyor

1. With excellent conveying speed, it can quickly transport materials from one location to another, greatly improving the flow efficiency of materials.

2. It can withstand large weight loads and is suitable for conveying materials of various weights. Whether it is light parts or heavy mechanical equipment, it can be transported smoothly on the roller conveyor.

3. It can adapt to the conveying of various types and shapes of materials, whether it is regular block objects, cylindrical objects, or irregularly shaped goods, they can be smoothly transmitted on the roller conveyor.

4. It can be flexibly customized according to different production site layouts and process flow requirements. Its length, width, height and conveying path can be adjusted and designed according to actual needs.

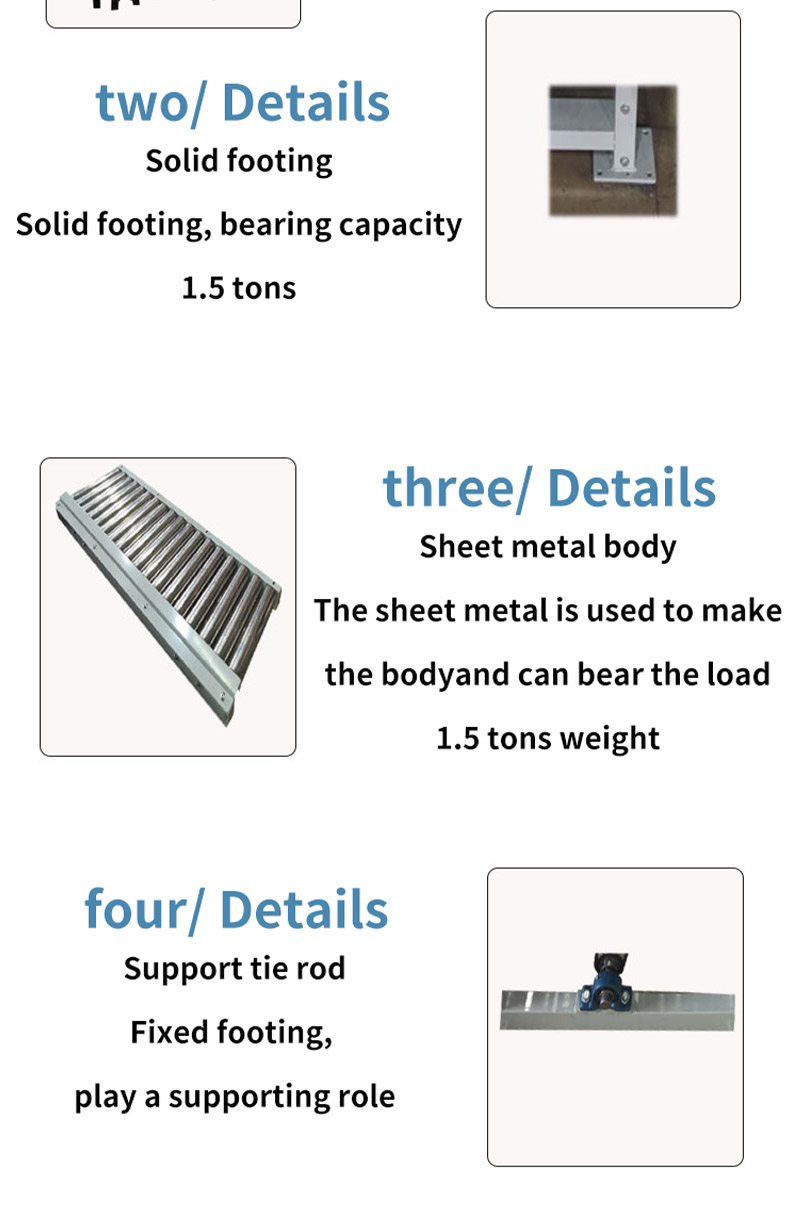

5. It adopts a relatively simple mechanical structure, mainly composed of rollers, brackets, drive devices and transmission components, etc., without overly complex parts and sophisticated control systems, so the failure rate is low.

6. Components such as rollers and chains can be easily disassembled and replaced, and the electrical control system is also relatively intuitive, which is convenient for debugging and maintenance.

Roller conveyor is a kind of material conveying equipment widely used in industrial production, logistics and warehousing, etc. It uses the rotation of a series of rollers to achieve smooth material transmission. Through the combination of ingenious mechanical design and advanced automatic control technology, roller conveyor can efficiently and accurately transport materials of various shapes, sizes and weights between different working areas.

The roller conveyor has high conveying efficiency and can quickly transport large amounts of materials to meet the needs of large-scale production and logistics distribution. Its conveying speed can be adjusted according to actual needs. By reasonably setting the conveying speed and optimizing the conveying process, the material turnover efficiency can be significantly improved and the production cycle can be reduced.

Due to the structural characteristics of the roller and the diverse surface treatment methods, the roller conveyor can adapt to the transportation of materials of various shapes, sizes and weights. Whether it is block, column, plate or irregular shape, it can be smoothly transported on the roller conveyor.

The structural design of the roller conveyor enables flexible layout, and can be customized according to the space limitations of the production site and the requirements of the process flow. It can be arranged in a variety of forms such as straight line, curved, climbing, branching, etc.

The structure of the roller conveyor is relatively simple. The main components such as rollers, brackets, transmission parts, etc. are usually made of strong and durable materials, and the maintainability of the components is fully considered in the design.

Application areas:

Industrial manufacturing: In the automotive manufacturing, mechanical processing, electronic and electrical industries, roller conveyors are widely used in various links of the production line for the transportation of raw materials, parts, semi-finished products and finished products.

Logistics and warehousing: In the logistics center, roller conveyors cooperate with shelves, forklifts, stackers and other equipment to form an efficient automated logistics system, realizing the rapid storage, outbound and sorting of goods.

Food and beverage industry: Its stainless steel rollers and surface treatment methods that meet food hygiene standards can ensure that food materials are not contaminated during transportation.

Chemical and pharmaceutical industry: In the chemical and pharmaceutical industry, roller conveyors are used to transport various chemical raw materials, pharmaceutical intermediates and finished drugs.

E-commerce and retail industry: With the rapid development of the e-commerce industry, roller conveyors are increasingly used in e-commerce warehouses and retail distribution centers.