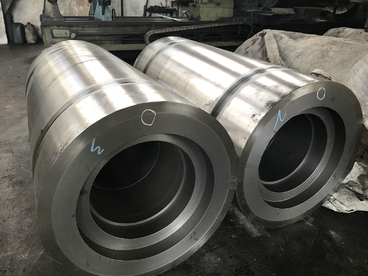

New Grease Roller for Flaking Mill

1. The use of new grease formula or unique grease storage and release structure can provide lubrication for the roller and other parts of the sheet rolling machine more evenly and permanently.

2. With more precise dimensional tolerances and surface flatness, it can ensure uniform pressure on the material during the sheet rolling process.

3. The use of advanced materials and surface treatment processes enhances the wear resistance of the grease roller.

4. With optimized sealing structure and materials, it can effectively prevent grease leakage

and external impurities, dust, etc. from entering the roller body.

5. The use of corrosion-resistant materials or protective coatings can prevent the roller body from being corroded and affecting performance and life.

In the field of sheet rolling, the lubrication system plays a key role in the stable operation of the equipment and the product quality. The new grease roller for sheet rolling came into being to provide a more efficient and reliable lubrication solution for the sheet rolling process.

Made of high-strength alloy steel and after a special heat treatment process, it has good wear resistance and fatigue resistance, ensuring that it is not easily deformed or damaged during long-term sheet rolling operations.

Equipped with double sealing device, the inner layer adopts rubber oil seal to effectively prevent grease leakage; the outer layer is a labyrinth seal to block external dust.

The unique grease storage chamber structure is designed to evenly release grease to the roller surface to ensure continuous and stable lubrication.

Good lubrication and anti-wear properties effectively reduce the friction between the flaking roller and the material, thereby extending the service life of the flaking roller and other parts of the equipment.

The product design fully considers the convenience of installation and disassembly, adopts standardized interfaces and installation methods, and can quickly complete installation and replacement, reducing equipment downtime.