Latest Roller Conveyor

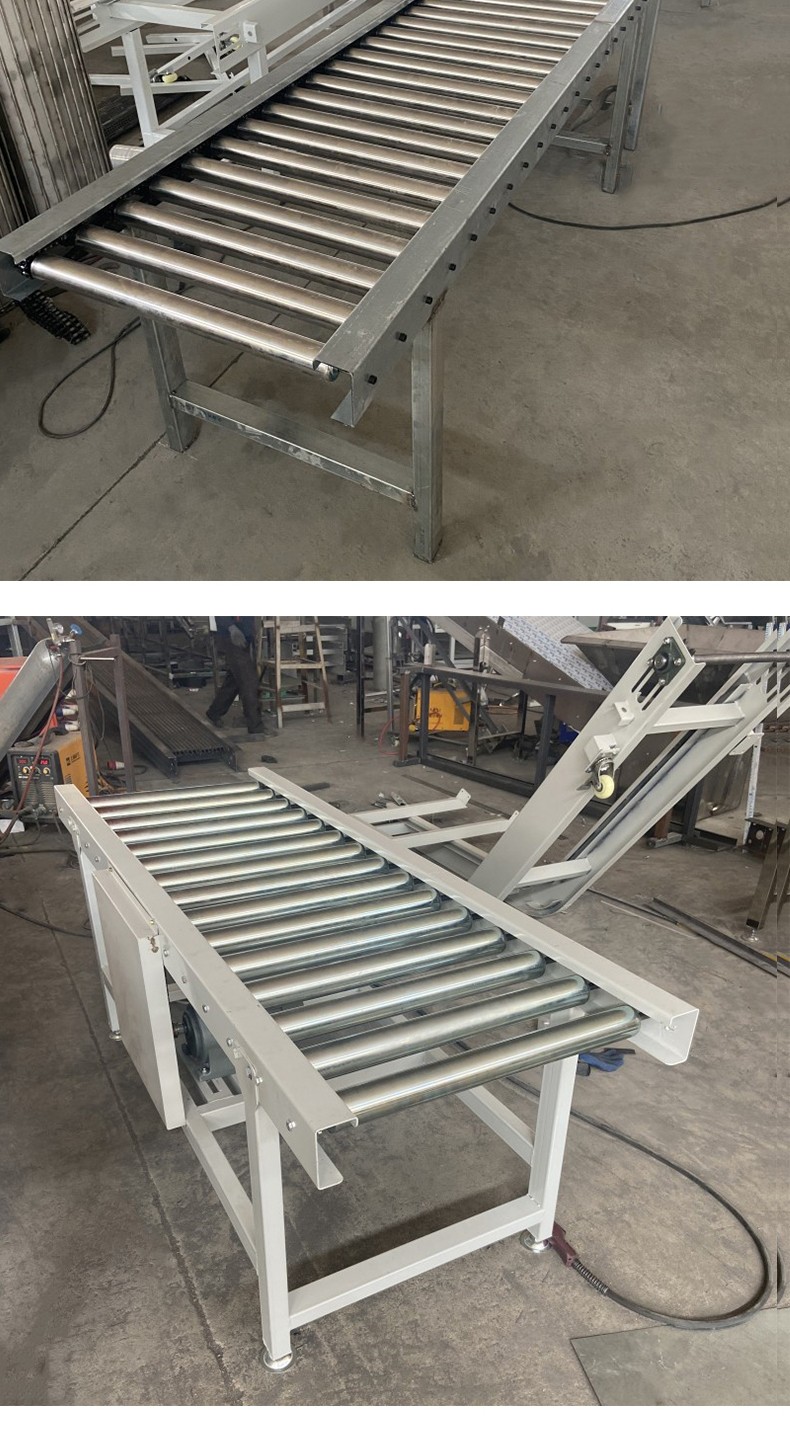

1.Latest Roller Conveyor usually adopts advanced power system and optimized Roller design, which can achieve higher conveying speed, so as to convey more materials in unit time.

2. Its structural design enables the material to move smoothly and continuously on the roller, reducing the pause and blockage of the material during the conveying process.

3. It is suitable for conveying materials of various shapes, sizes and weights. Whether it is regular-shaped items such as boxes, bags, barrels, or irregular-shaped workpieces.

4. It can be used in different working environments. By adopting special materials and protective measures, such as stainless steel rollers, dust covers, etc., the normal operation and service life of the conveyor can be guaranteed.

5. The roller rotates smoothly, and the friction between it and the material is uniform, so that the material will not be violently bumped and shaken during the conveying process.

Latest Roller Conveyor relies on the friction between the rotating roller and the object to move the object forward. When the drive device is started, the roller begins to rotate, and the material placed on the roller moves forward due to the friction with the roller surface, thereby realizing the transportation of materials from one location to another.

High conveying efficiency: It can achieve a higher conveying speed, and the material moves smoothly and continuously on the roller, which can effectively increase the material conveying volume per unit time and improve production or logistics efficiency.

Brand: bremetz

Material: Aluminum alloy, carbon steel spray paint, stainless steel

Drum: galvanized tube face, stainless steel tube face, coated barrel (customizable)

Whether to process customized:

Working length:1000MM-30000MM (support customization)

Working height: 750-1500MM(customizable)

Features:It has the characteristics of large conveying capacity, fast speed, light running, and can realize the characteristics of multi-variety collinear shunt conveying.

It is suitable for materials of various shapes, sizes and weights. As long as the bottom of the material is flat and can be supported by at least three rollers, stable transportation can be achieved. At the same time, it can also adapt to different working environments. By selecting appropriate materials and protective measures, it can operate normally under harsh conditions such as high temperature, low temperature, humidity, dust, etc.

The structure is relatively simple, and the manufacturing process and quality control of the main components are mature, which reduces the probability of failure. The roller rotates smoothly, and the friction between the roller and the material is uniform, which can avoid the violent bumps and shakes of the material. The advanced driving technology and shock absorption device can reduce the noise during the operation of the equipment.

The structure is relatively simple, and the manufacturing process and quality control of the main components are mature, which reduces the probability of failure. The roller rotates smoothly, and the friction between the roller and the material is uniform, which can avoid the violent bumps and shakes of the material. The advanced driving technology and shock absorption device can reduce the noise during the operation of the equipment.

According to different needs of users, conveyors of various sizes and specifications, such as width, length, height, etc., can also be customized, and auxiliary functions such as accumulation, sorting, turning, etc. can be added to meet the requirements of different places and complex logistics operations.

Equipped with complete protective devices such as guardrails, protective covers, emergency stop buttons, etc., it can effectively prevent operators from contacting moving parts and avoid accidental injuries. In addition, stable operation also reduces the risk of accidental falling and leakage of materials.