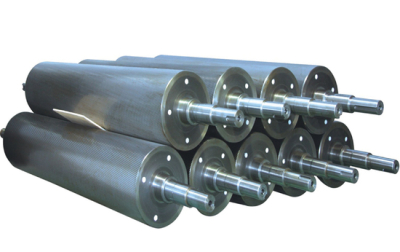

Grease rollers for flaking mills

1. Using high-quality materials and advanced manufacturing technology, the surface hardness is high and uniform, which can effectively resist the continuous friction and wear of the material during the tableting process.

2. With a highly accurate gap adjustment system, the operator can make fine adjustments according to the characteristics of different materials and the required tableting thickness, and the error can be controlled within a very small range.

3. It can flexibly respond to the hardness, shape, humidity and other changing factors of different materials, and efficiently press various materials into ideal thin sheet forms.

4. It can accelerate the softening and deformation process of the material, reduce the time and energy consumption required for tableting, and help improve the internal structure and quality of the material, and improve the overall performance of the product.

5. The surface is coated with special lubricating grease or self-lubricating materials, which effectively reduces the friction between the material and the roller and reduces the adhesion of the material on the roller surface.

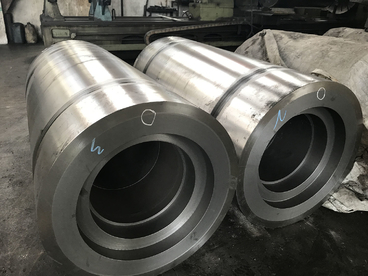

The grease roller of the tablet press adopts a sturdy and durable integral structural design and is carefully made of high-quality metal materials to ensure stable performance under long-term and high-intensity working conditions.Its core design concept focuses on achieving efficient and accurate material tableting operations, while taking into account the convenience of operation, ease of maintenance and wide adaptability to different material characteristics.

With advanced roller manufacturing technology and precise gap adjustment mechanism, efficient and accurate sheeting of materials can be achieved. Whether it is fine sheets as thin as 0.1 mm or special sheets as thick as several millimeters, they can be stably produced within a strict thickness tolerance range.

The technology of combining the grease lubrication system with the internal cooling channel of the roller effectively solves the problems of frictional heat generation and adhesion during the material tableting process.

Equipped with advanced intelligent control systems, it can realize remote monitoring, automatic diagnosis and fault warning of equipment. Operators can view the operating status, various parameters and production data of the equipment in real time through terminal devices such as computers or mobile phones, and perform remote operations and adjustments.

Environmental protection, energy saving and safety factors are fully considered during the design process. The energy-saving transmission system and efficient heat exchange technology adopted reduce the energy consumption of the equipment.

Scope of application:

Food industry: Grease rollers can accurately control the thickness and quality of tablets according to the characteristics of different food raw materials, and produce products that meet the taste and nutritional needs of consumers.

Agricultural field: Grease rollers can evenly press seeds into thin slices while ensuring the integrity of seeds, making it easier to extract oil.

Pharmaceutical industry: In the pharmaceutical process, many drugs need to be made into tablets or capsules. Grease rollers can be used to press drug raw materials into uniform thin slices for subsequent tableting or filling processes.

Chemical industry: Used for tableting of some chemical raw materials, such as pressing certain metal powders, plastic particles or chemical intermediates into thin slices of specific shapes and thicknesses for easy storage and transportation.