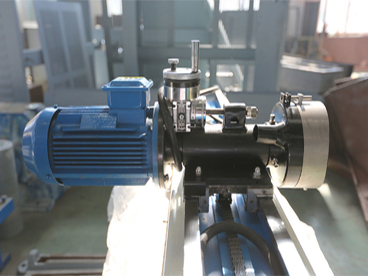

Automatic roller grinding machine

1. Equipped with high-precision grinding heads and advanced grinding processes, it can achieve micron-level or even higher precision grinding.

2. Integrated with high-precision measurement system, it can monitor the grinding status and size changes of the roller in real time and feed back the data to the control system.

3. Adopting automated loading and unloading devices and grinding processes, it can realize automatic clamping, positioning, grinding and unloading of rollers.

4. With fast roller changing mechanism and convenient parameter adjustment function, it can complete the replacement and grinding parameter setting of rollers of different specifications in a short time.

5. It usually has multi-axis linkage function, which can control the movement of multiple coordinate axes at the same time to realize complex grinding trajectory and shape processing.

Automatic roll grinder is a high-precision CNC equipment specially used for grinding various types of rolls. It is widely used in steel, non-ferrous metals, papermaking, rubber, plastics and other industries.

It can perform precision grinding on various surfaces of the roller, such as the outer circle, inner hole, conical surface, step surface and end face, to ensure that the roller has good accuracy and surface quality during the rolling process, thereby improving the quality of the rolled products.

The use of advanced grinding technology and high-precision grinding heads, combined with precise measurement and feedback systems, can achieve micron-level precision grinding.

The quick roll changing and multi-axis linkage functions can complete the replacement of rolls of different specifications and the processing of complex shapes in a short time, reducing downtime and improving production flexibility.

The machine body is made of high-strength material and has a reasonable structural design, with good rigidity and can withstand high grinding loads.

The energy-saving drive system is adopted to automatically adjust the power according to the grinding load to reduce energy consumption.