What are the benefits of corn after corn press?

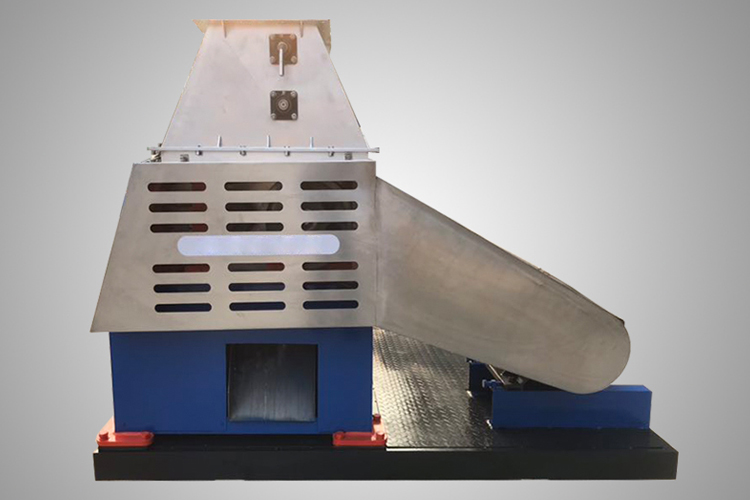

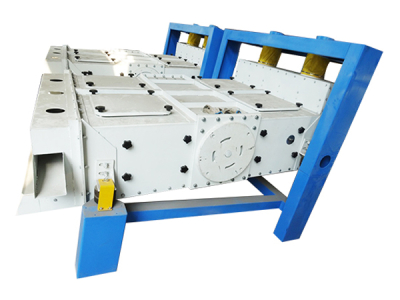

Steam flake treatment of corn is to expand and soften the corn through steam hot processing, and then peel and fracture these expanded corn with mechanical pressure generated by a pair of reverse rotating rollers, and process the corn into a specified density of flakes. The mechanism is actually a gelation process, which means that tightly bound corn starch breaks the hydrogen bond of starch binding in cells through gelation, so as to improve the digestibility of corn starch in animals. In addition, the chemical structure of proteins in corn was changed during the treatment process, which was conducive to rumen absorption of proteins. Moisture, heat, treatment time and mechanical action are the main factors that promote the gelation process and improve the overall digestibility of corn treated with steam tablet.

The function of water is to expand and soften; Heating can make electrons move, destroy hydrogen bond and promote gelation reaction. Sufficient steam conditioning treatment time is the guarantee of sufficient gelation process; The mechanical function of the roller is a process of crushing molding and reaching the specified tablet density. The whole process is a process of starch gelatinization, through which the hydrogen bond tightly bound to starch is destroyed, and the structure of protein is also changed. The grain is expanded and softened through steam thermal processing. The expanded corn is then stripped and fractured by mechanical pressure generated by a pair of counter-rotating rollers, and the corn is processed into flakes of specified density. In addition, the chemical structure of corn protein was changed during the process of steam compression, which was conducive to rumen absorption of protein. Water, heat, treatment time and mechanical action are the main factors in the process of steam tablet treatment of corn. Water makes corn expand and soften; heating can make electrons move, destroy hydrogen bonds (long molecular chains of starch), and promote gelation reaction. Sufficient steam disposal time is the guarantee of full gelation process. The role of the roll is the process of extrusion molding with mechanical force to achieve the specified sheet density.