Fully automatic aluminum sealing machine promotes industry progress

Improved intelligent automation: Today's fully automatic aluminum foil sealing machines continue to integrate advanced technologies such as the Internet of Things and artificial intelligence. By integrating sensor technology and data analysis functions, the equipment can achieve more accurate product packaging and provide real-time monitoring and predictive maintenance services, thereby improving production efficiency and product quality. For example, some equipment uses PLC control systems and touch screen operation interfaces to achieve automated and intelligent production, improve production efficiency and product quality, and reduce labor costs and the impact of human factors on sealing quality.

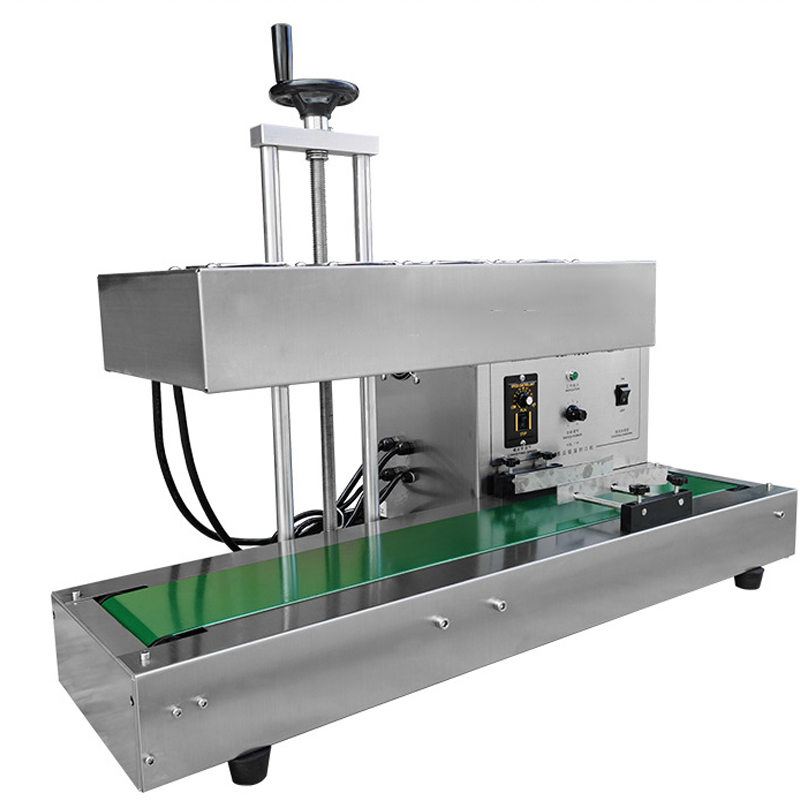

High-efficiency sealing technology research and development: Using advanced heating systems and precise temperature control technology to achieve high-speed and efficient aluminum foil sealing, ensuring product sealing and shelf life. Some sealing machines also have an automatic thickness measurement system that can automatically adjust relevant data according to the thickness of the aluminum strip to further optimize the sealing effect.