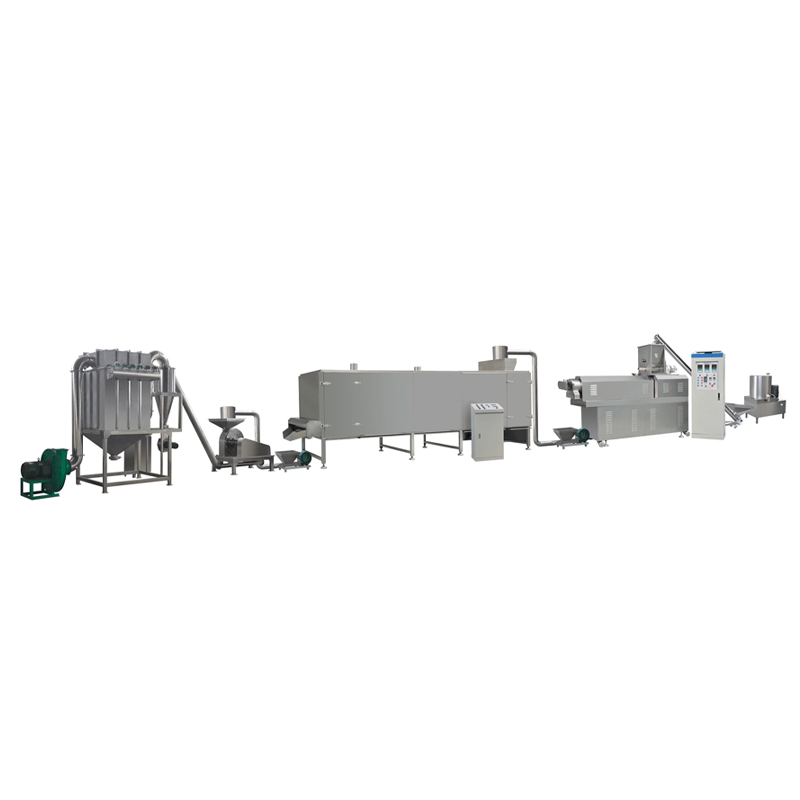

Corn puffing automatic production equipment

1. The equipment usually adopts advanced automatic control system, and the whole production process can be automated, reducing manual operation links.

2. The equipment has efficient puffing capacity and can process a large amount of corn raw materials in a short time.

3. By accurately controlling parameters such as temperature, pressure and screw speed, the equipment can make the corn evenly heated and fully puffed.

4. During the puffing process, the nutrients in the corn can be retained to the greatest extent, improving the nutritional value of the product.

5. Automated production reduces the interference of human factors in the production process, so that the quality of each batch of products can remain stable.

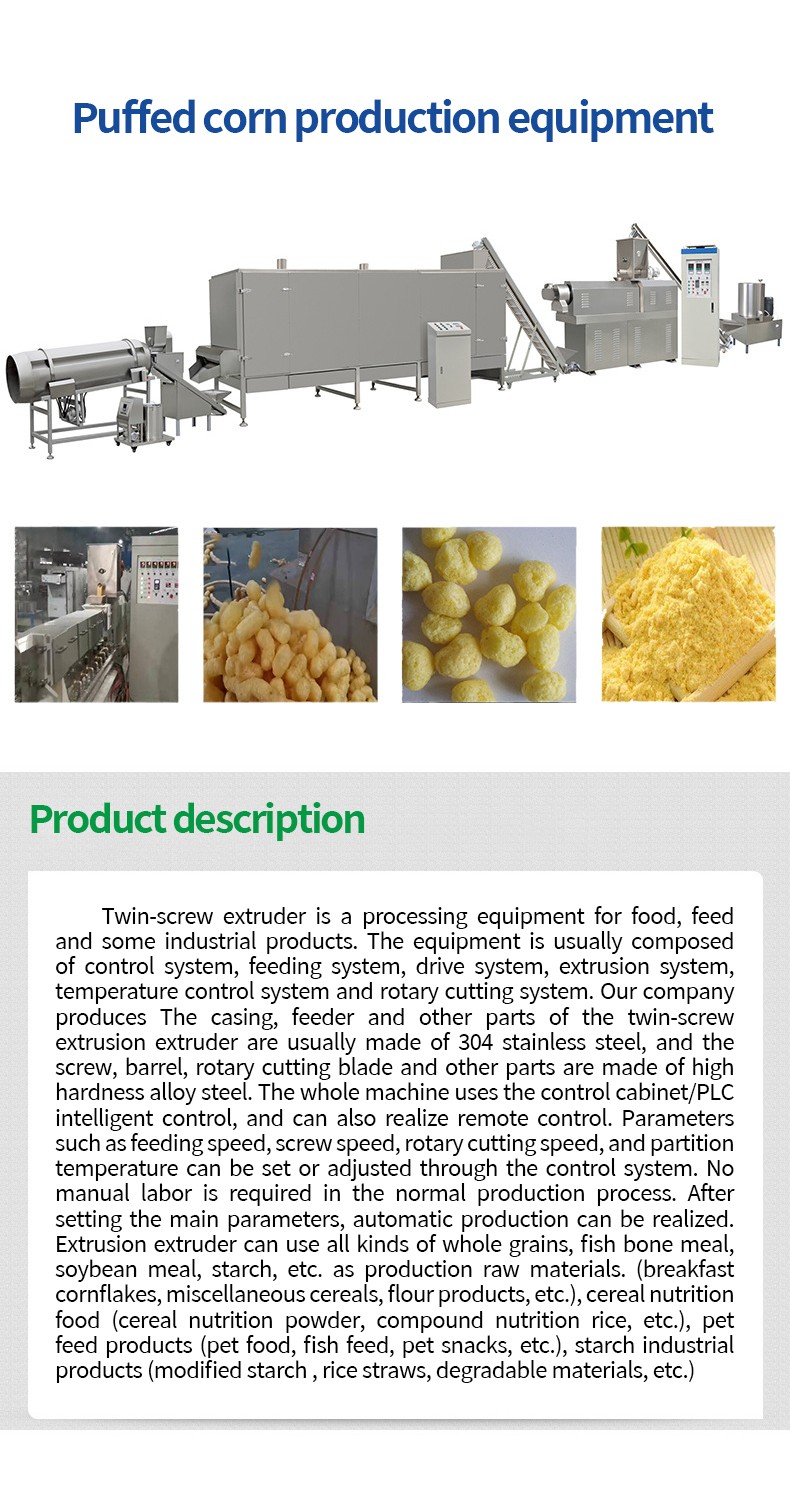

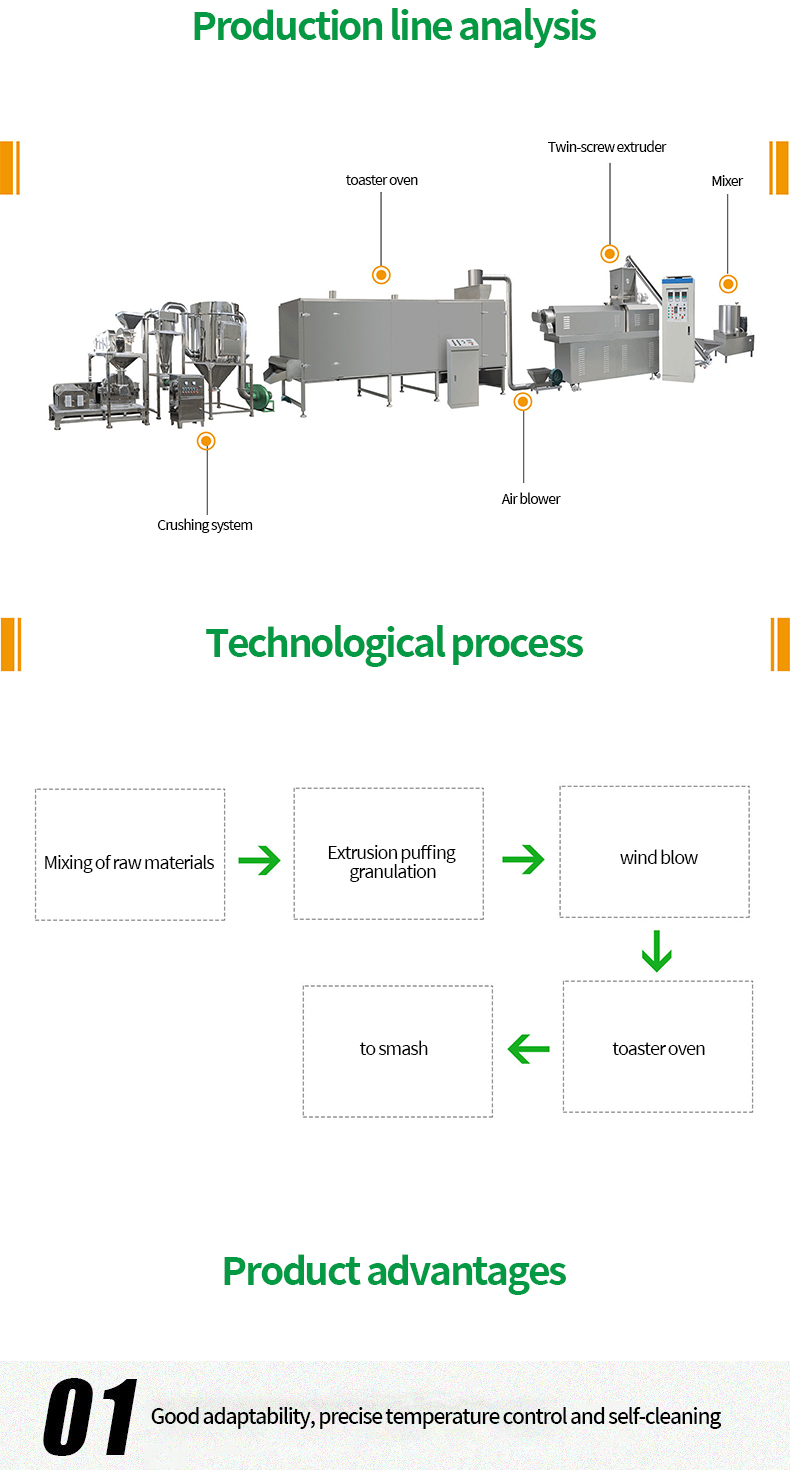

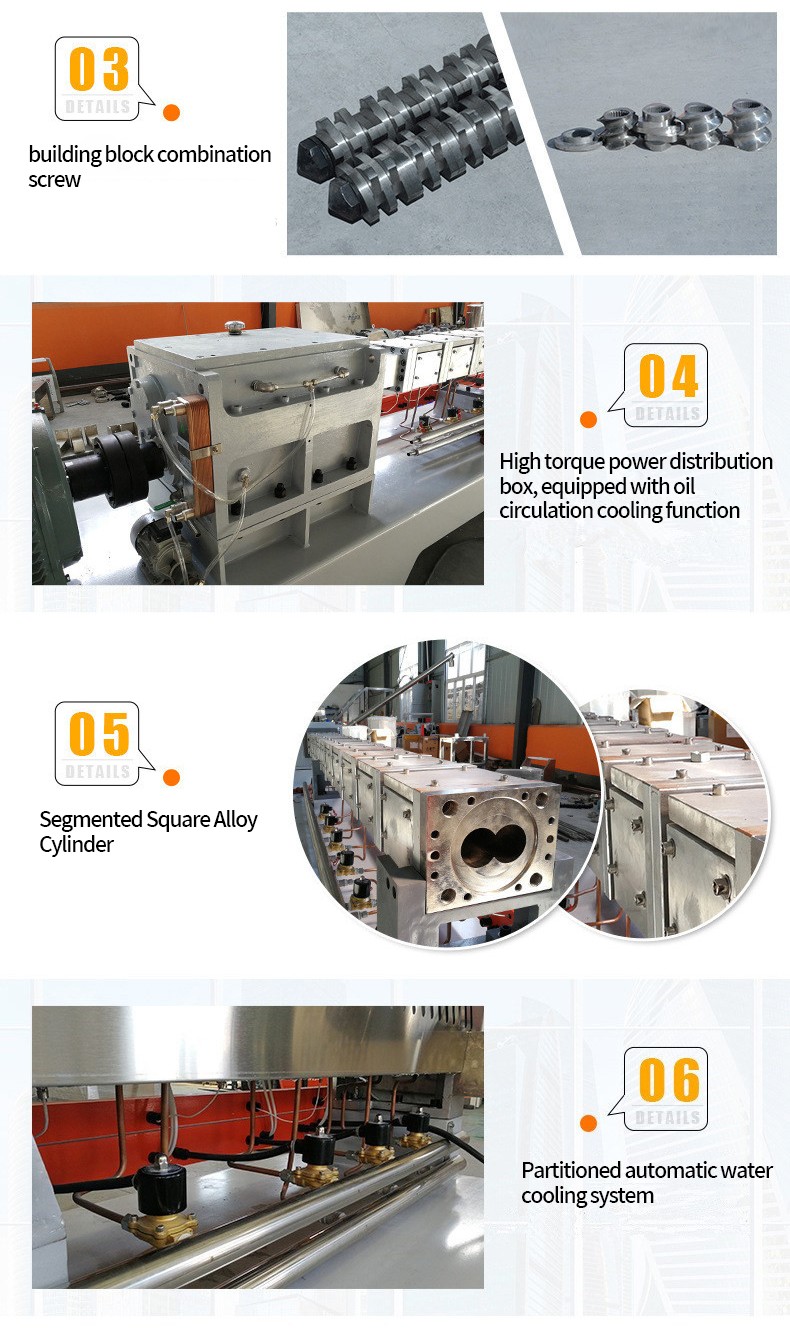

Usually the extrusion puffing principle is used. After the corn raw material enters the equipment, it moves forward under the push of the screw. At the same time, the heating system inside the equipment keeps the material in a high temperature and high pressure environment. When the material is extruded from the die, the pressure drops suddenly, the water vaporizes instantly, and the corn expands rapidly to form an expanded product.

From raw material preparation, extrusion and puffing, sandwiching, molding, cutting, spraying, seasoning to finished product is completed in one go.

Advanced parameter control and process flow ensure stable quality of processed products.

Equipped with a user-friendly operation interface, operators can operate it proficiently after simple training.

It is equipped with safety protection devices, meets environmental protection requirements and reduces pollution to the environment.

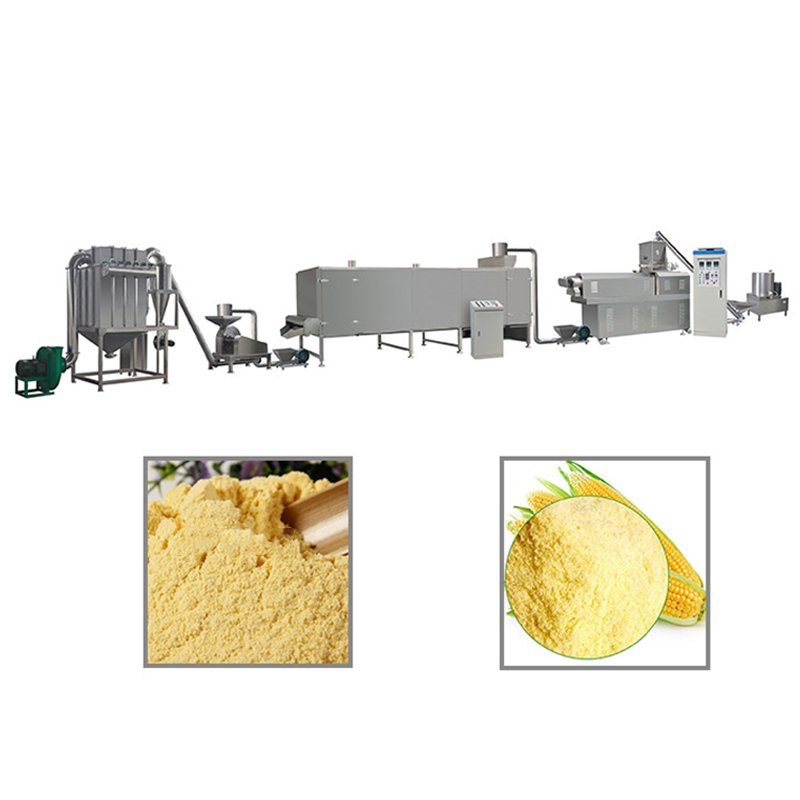

By precisely controlling the process parameters, the product has a uniform puffing effect, a crispy taste, good nutritional retention, a beautiful appearance, and little difference in product quality between batches.

By replacing different molds and adjusting process parameters, products of various shapes, sizes and flavors can be produced to meet the diverse needs of the market.