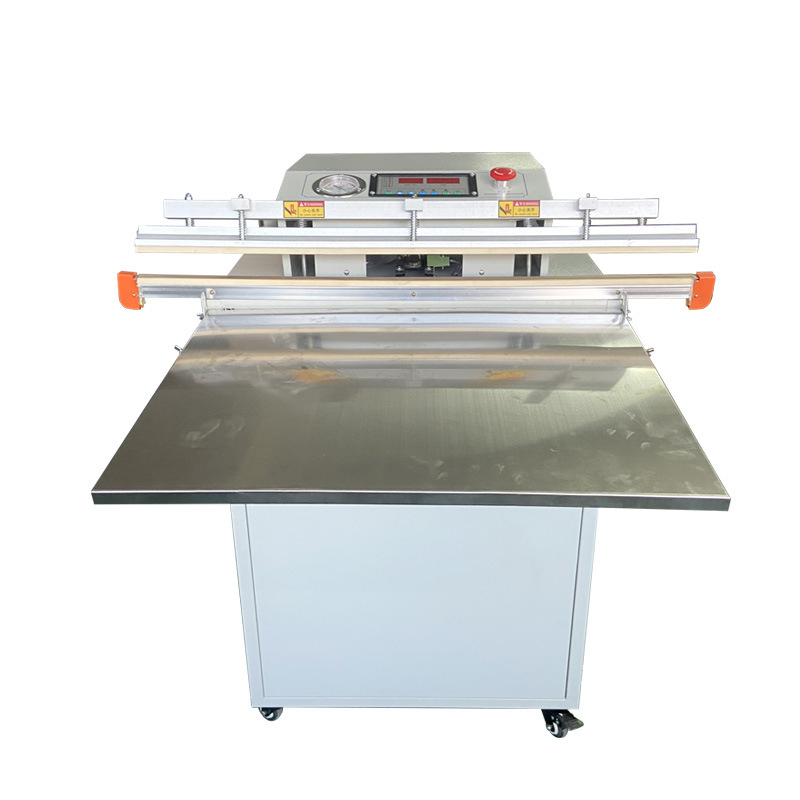

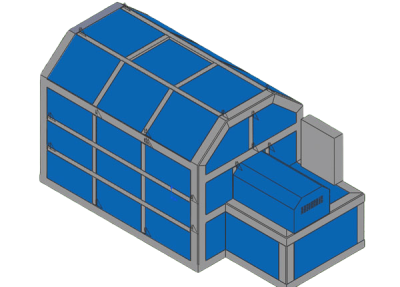

Vacuum sealing packaging machine

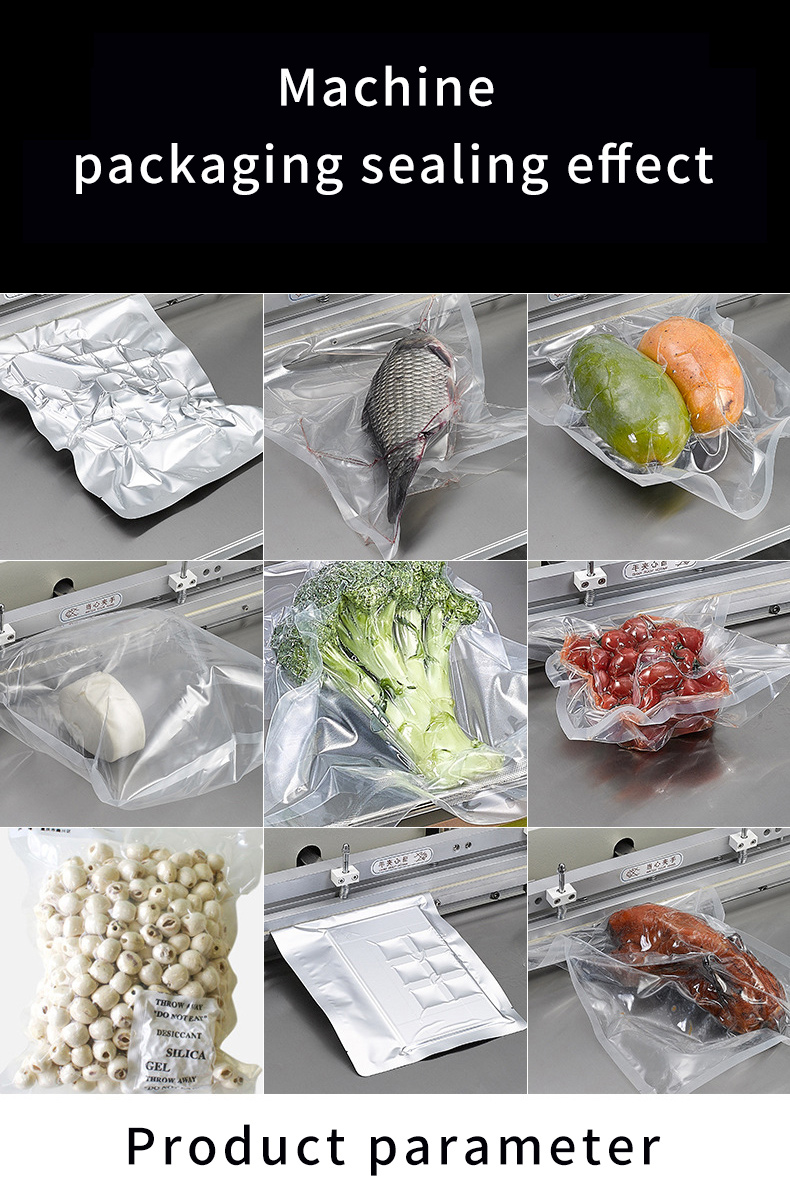

1. Effectively reduce oxygen content, inhibit the growth and reproduction of aerobic microorganisms and the occurrence of oxidation reactions.

2. Vacuum packaging can prevent the invasion of oxygen, moisture and odor, and maintain the original flavor, color, nutrients and performance of the product.

3. It can provide a certain buffer protection for the product and reduce the physical damage caused by collision and extrusion during handling, transportation and storage.

4. After the air is extracted, the package will fit the product tightly, thereby reducing the total volume of the package, saving storage space and transportation costs.

5. The vacuum packaging machine can complete the packaging process of a single product in a shorter time, meeting the production needs of enterprises of different scales.

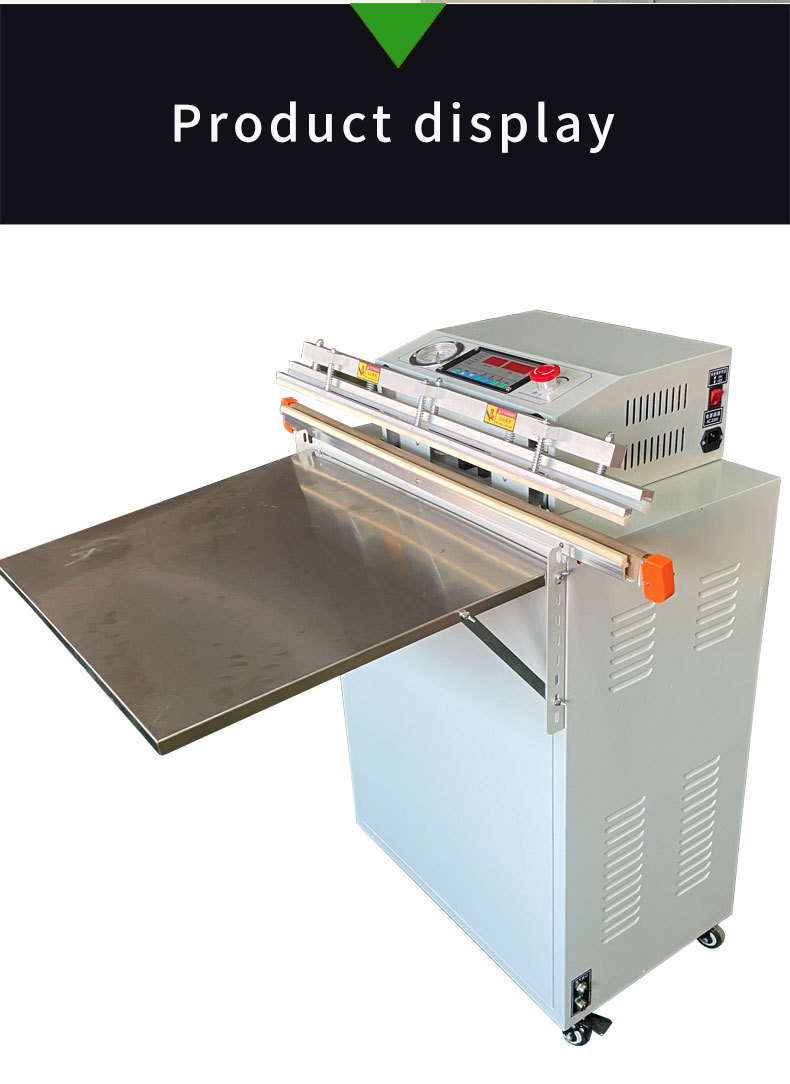

This vacuum packaging machine is a packaging equipment that integrates advanced technology and high-efficiency performance, designed to meet the needs of various industries for product preservation, protection and efficient packaging. It can provide high-quality vacuum packaging solutions, effectively extend the shelf life of products and maintain product quality.

Made of high-quality stainless steel, it is sturdy and durable, with good anti-corrosion performance. It can not only adapt to various production environments, but also meet the hygiene standards of the food, pharmaceutical and other industries.

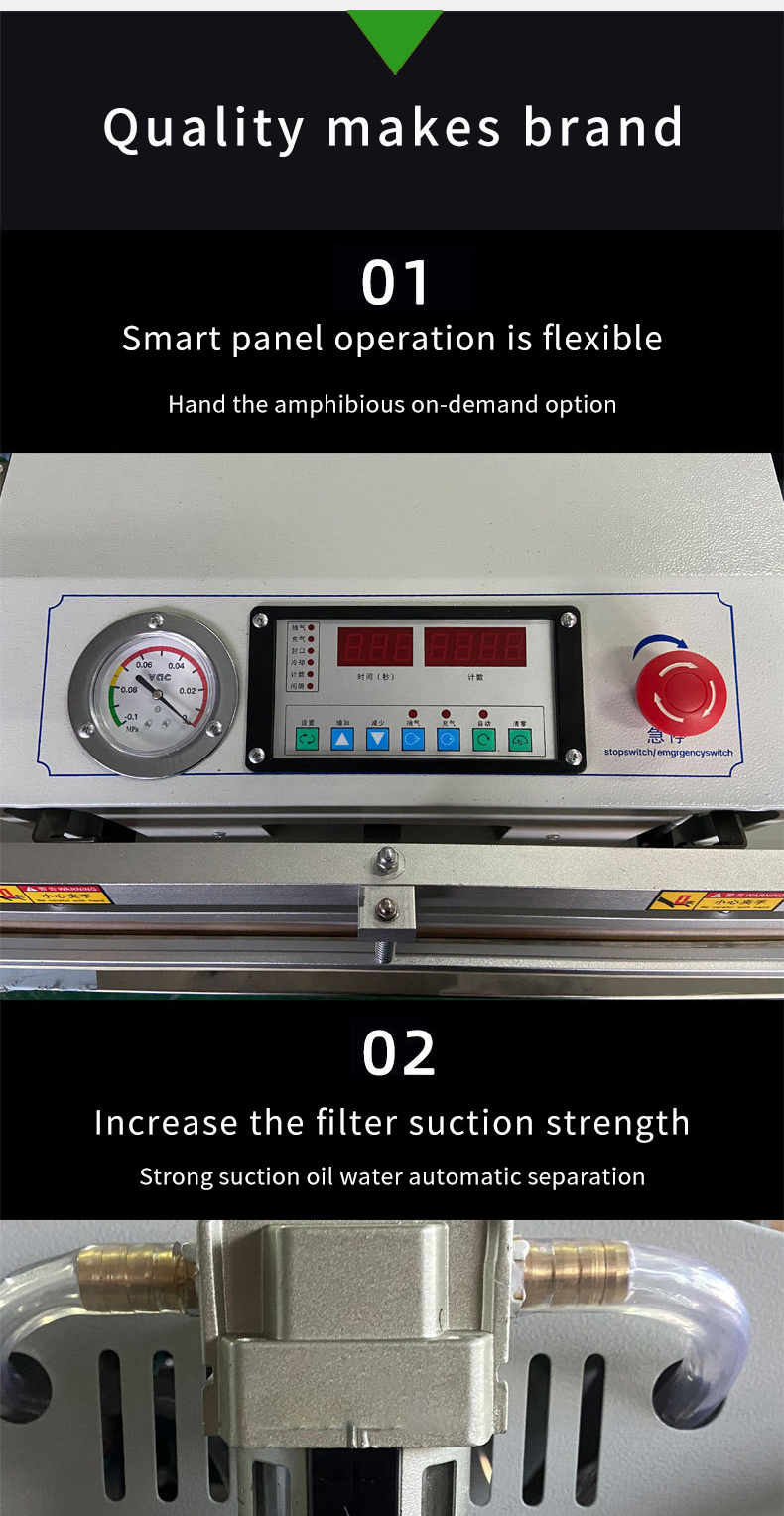

Using advanced heat sealing technology, the sealing mold is customized according to different packaging materials and sealing width to ensure the firmness and airtightness of the seal.

Power Supply: 200V/50HZ

Motor power: 1.8KW

Model: Type 800

Charging power: 0.8mpa

Sealing size: 800*10mm

Weight: 76kg

Pumping power:20m³/h

Overall dimensions: 900*450*950mm

It has a high packaging speed and can complete vacuum packaging operations of dozens to hundreds of products per hour depending on the product size and packaging form.

By precisely controlling the sealing temperature, time and pressure, a firm and airtight sealing effect is achieved. The sealing is flat and smooth without any defects such as leakage, bubbles or wrinkles.

It can adapt to the packaging needs of products of various shapes, sizes and materials. Whether it is small electronic components or large industrial parts, perfect vacuum packaging can be achieved by adjusting the packaging parameters.

Related Products