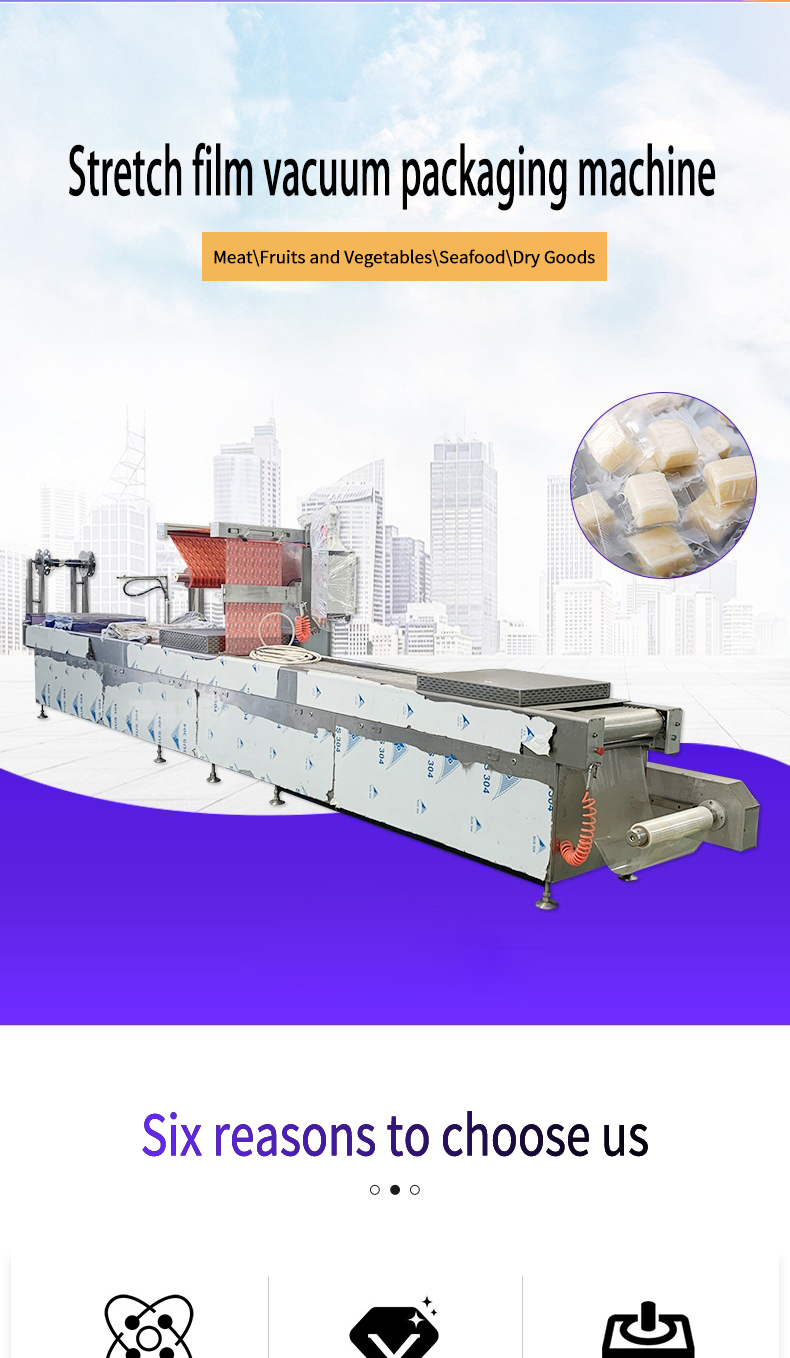

Stretch film vacuum packaging machine

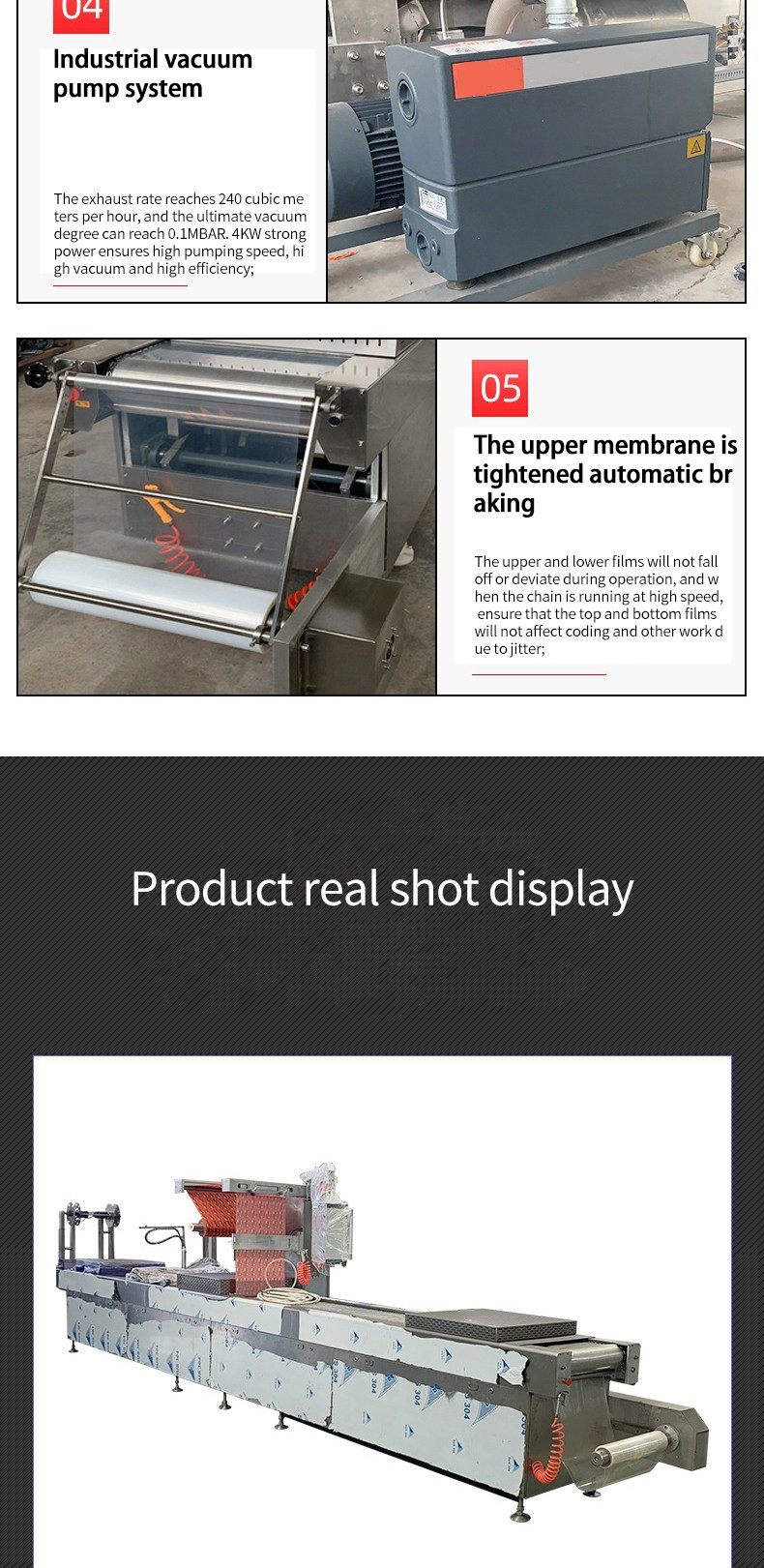

1. It can achieve a better vacuum packaging effect, effectively extract the air in the package and reduce the oxygen content.

2. The stretch film has good ductility and tear resistance, and can fit products of various shapes and sizes tightly.

3. Compared with traditional pre-made bag packaging, the stretch film is used in rolls and can be made into bags on site according to the size and shape of the product.

4. The highly automated production process greatly improves production efficiency and reduces the labor intensity of workers.

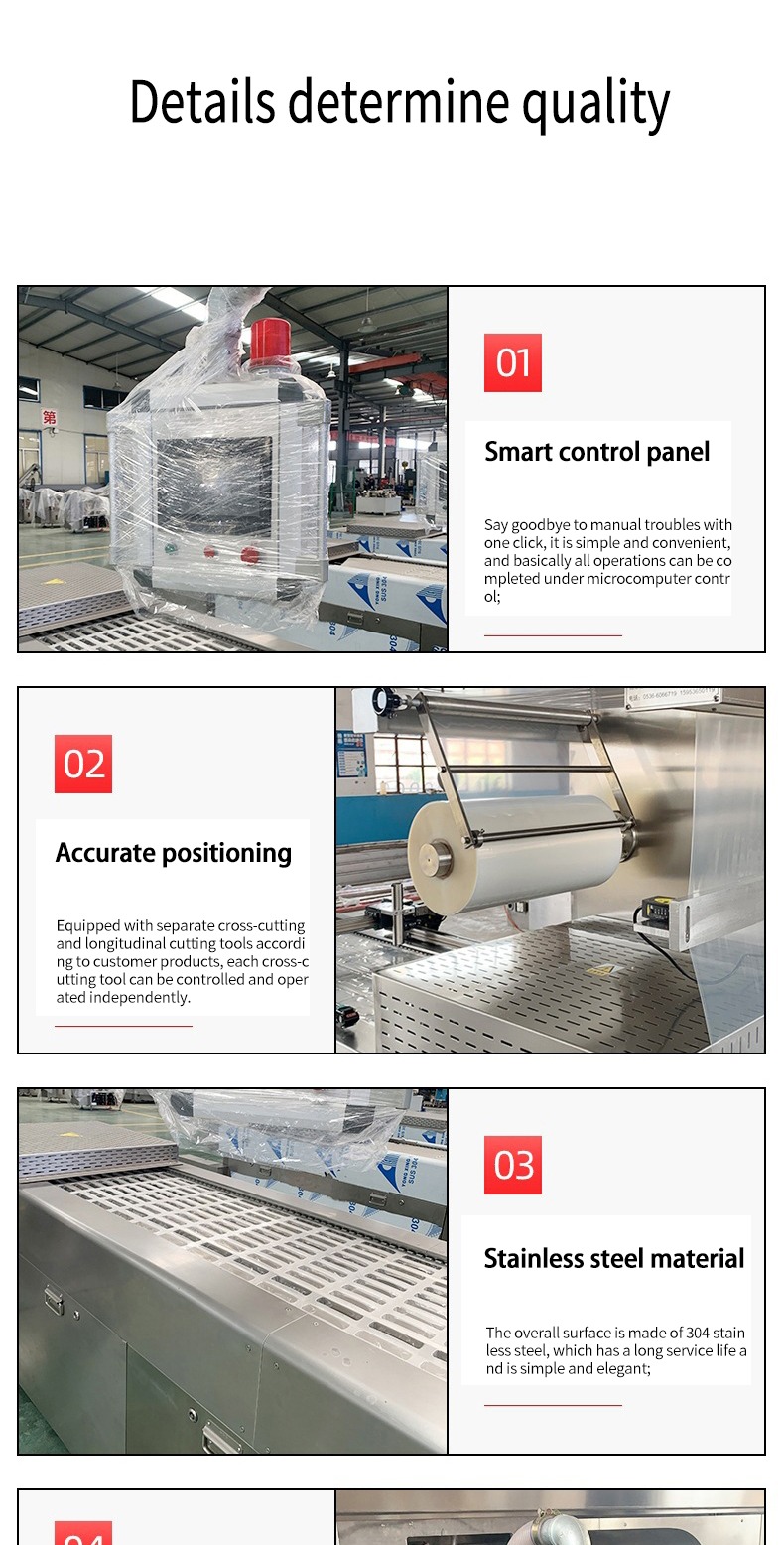

5. The whole machine is usually made of hard aluminum-magnesium alloy and stainless steel materials, which has good corrosion resistance.

6. It can achieve continuous automated packaging operations without frequent shutdowns to replace packaging bags or other manual operations.

Stretch film vacuum packaging machine is an advanced packaging equipment, which integrates multiple functions such as stretch film forming, vacuuming, inflation (optional), sealing, etc. It is widely used in many industries such as food, medicine, electronics, chemical industry, etc.

The frame is made of solid stainless steel or aluminum alloy, which has good strength and stability. It can withstand various forces generated during the operation of the equipment and ensure the firmness and reliability of the overall structure.

Through advanced control systems and sophisticated mechanical structures, the forming dimensions, vacuum degree, inflation volume, sealing temperature and pressure of the stretch film can be accurately controlled.

It has excellent packaging adaptability for products of various shapes, sizes and materials. Whether it is a block, granular, powder or liquid product, it can achieve perfect packaging effect by customizing the appropriate mold and adjusting the equipment parameters.

Using high-quality stretch film materials and advanced packaging technology, the packaged products have good sealing, moisture resistance, oxidation resistance and impact resistance.+

The design focuses on energy conservation and environmental protection, adopts high-efficiency and energy-saving vacuum pumps, motors, heating elements and other components, and reduces the energy consumption and operating costs of the equipment by optimizing the equipment's operating procedures and process parameters.