Self-propelled wrapping machine

1. It can automatically complete the packaging process of goods without excessive manual intervention, which greatly improves packaging speed and production efficiency.

2. Reduces reliance on manual packaging, requiring only a few operators to monitor and perform simple operations on the equipment, significantly reducing the company's labor costs.

3. The machine can accurately control the tension, overlap and winding path of the packaging film, ensuring that each product or pallet of goods can receive an even, tight and consistent packaging effect.

4. Some self-propelled winding packaging machines can be customized according to different product sizes, shapes and packaging requirements.

5. Have good flexibility and adaptability, able to handle goods of various shapes, sizes and weights.

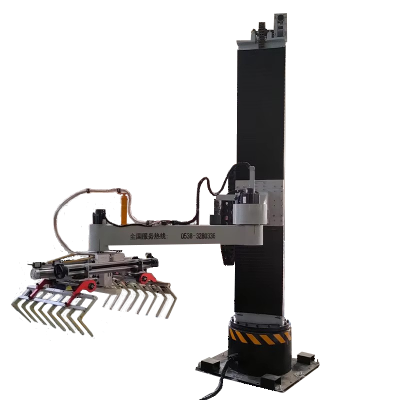

6. The self-propelled design can flexibly move to different work areas for packaging operations according to the layout and actual needs of the production site.

The self-propelled wrapping machine is an advanced automated packaging equipment specially designed for efficient and accurate wrapping of various goods. It integrates technologies from multiple fields such as mechanical engineering, automated control, and materials science.

The advanced pre-stretching mechanism is used to accurately pre-stretch the packaging film through multiple sets of rollers or mechanical structures. This technology can stretch the film to the appropriate proportion according to different film materials and packaging requirements.

Equipped with high-precision photoelectric sensors to detect various information of goods in real time. During the packaging process, photoelectric sensors can accurately measure the height, width, length and other dimensional parameters of the goods.

There are a variety of packaging modes to choose from to meet the packaging needs of different industries and products. It can adapt to the packaging of goods of various shapes, sizes and weights.

With its automated packaging process and optimized mechanical structure, the self-propelled wrapping machine has extremely high packaging efficiency.

Thanks to the use of advanced pre-stretching technology, precise photoelectric sensing and intelligent control system, the self-propelled wrapping machine can ensure the consistency and stability of packaging quality.

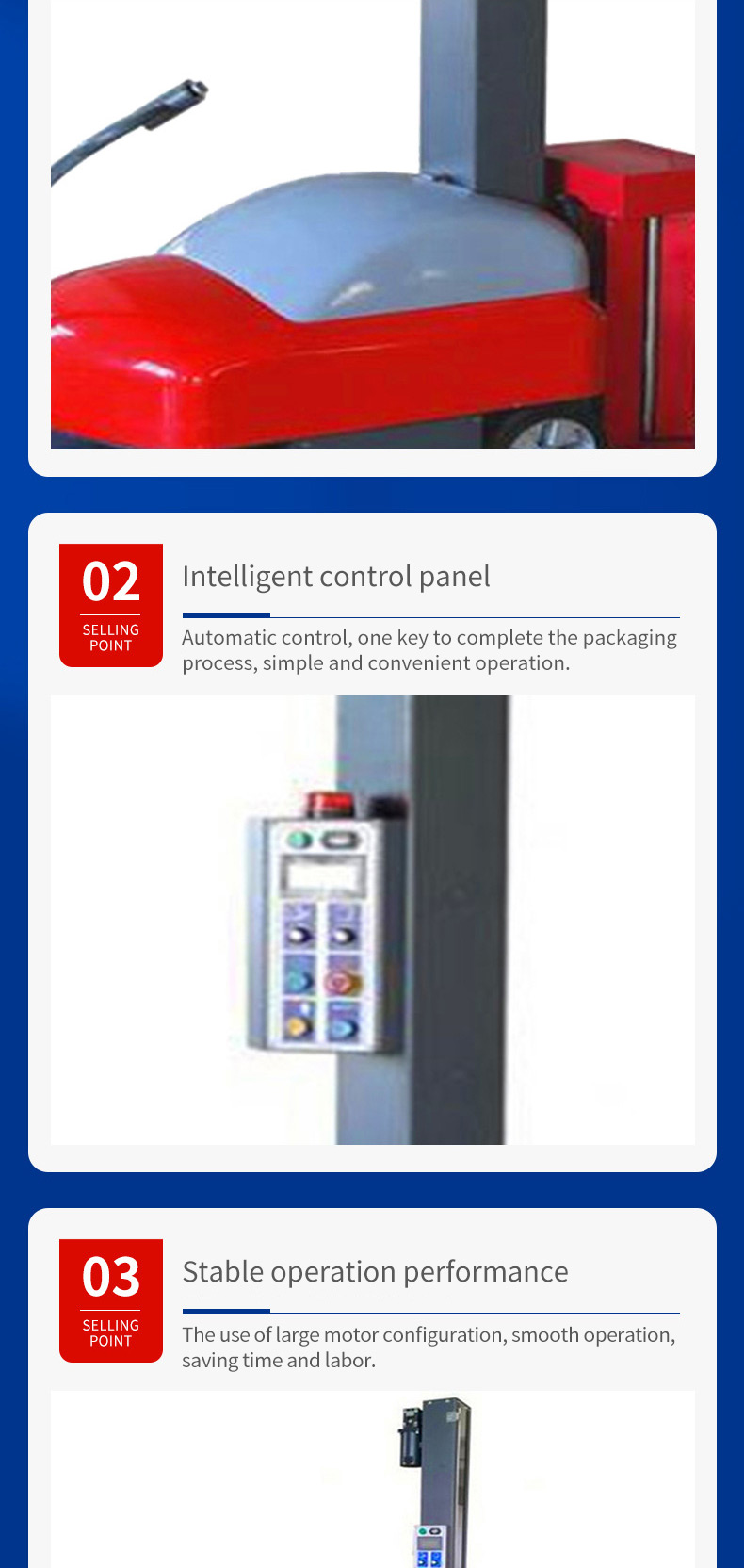

The design focuses on user experience and is simple and convenient to operate. The daily maintenance of the equipment is also relatively convenient, mainly focusing on routine work such as cleaning, lubrication, and inspection of wearing parts.

In order to improve the packaging quality and convenience, self-propelled wrapping machines are usually equipped with some auxiliary devices. For example, the top pressing device is used to compact the top of the goods during the wrapping process to prevent the goods from shaking or shifting during the packaging process.