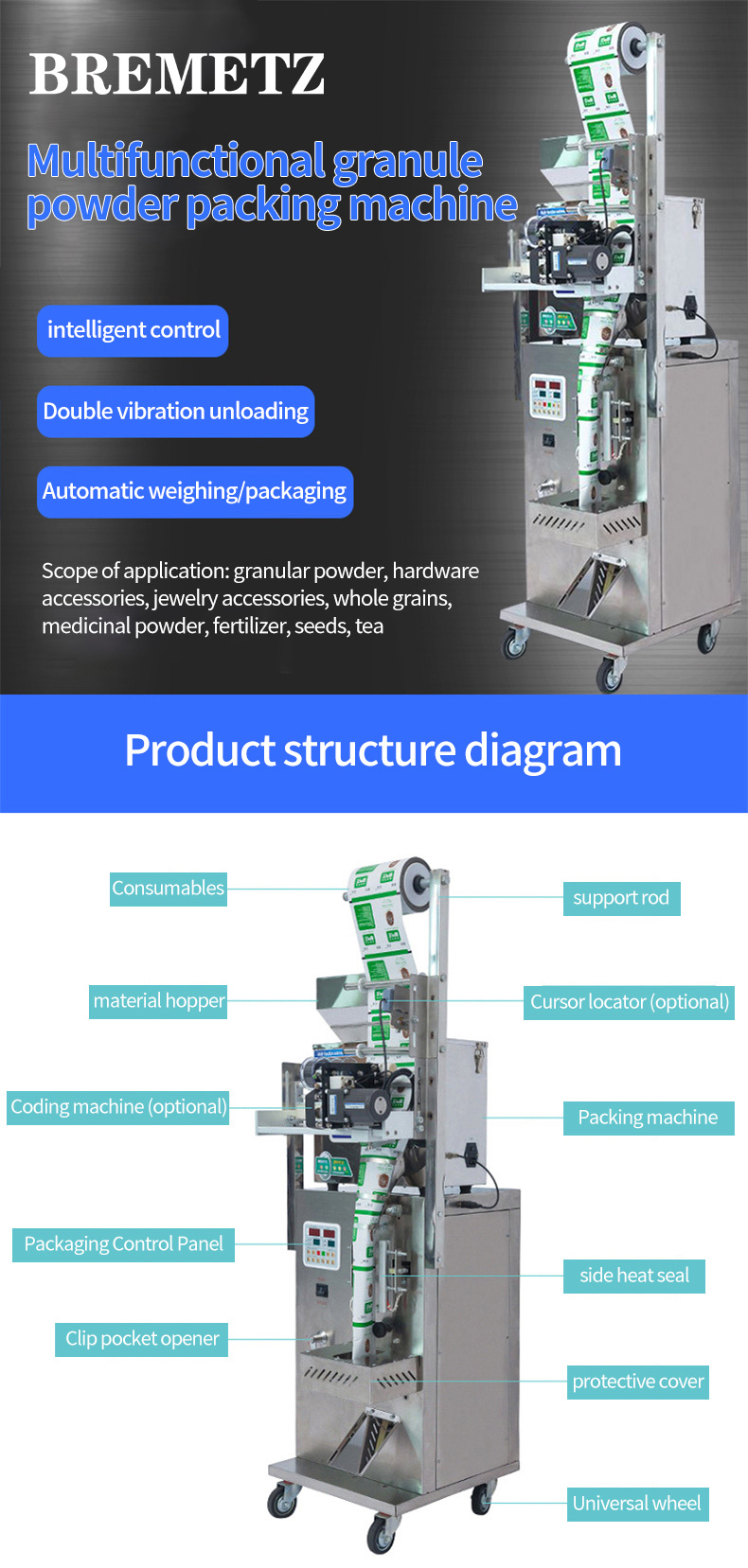

Multifunctional Granule Powder Packaging Machine

1. The high-precision metering device can accurately measure granular and powder materials to ensure that the weight or volume error of each bag is extremely small.

2. It has an automatic calibration function, which can automatically calibrate the metering system regularly to reduce metering deviations caused by long-term use or environmental changes.

3. The advanced transmission system and control technology are adopted, and the packaging speed is fast, which can greatly improve production efficiency and save labor costs and time costs.

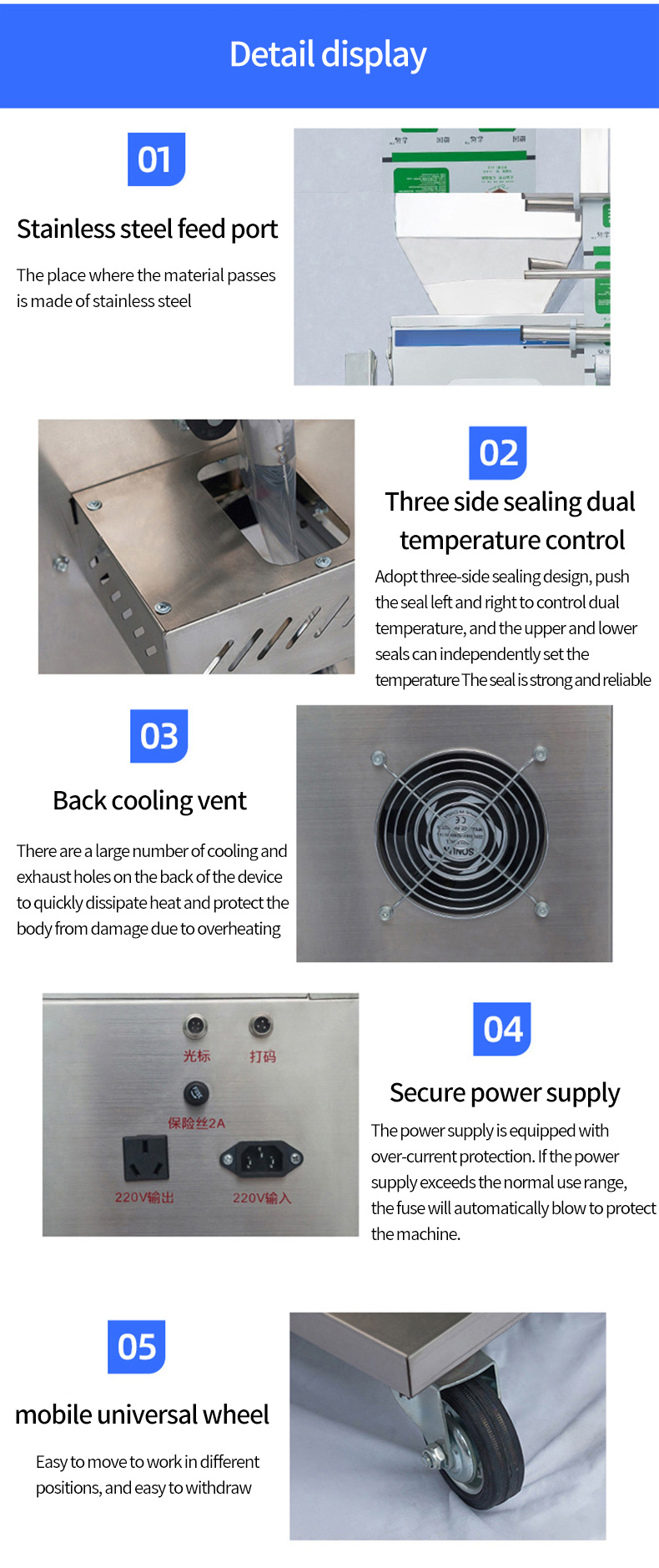

4. The equipment structure is reasonably designed, and each component operates stably. It can work continuously for a long time and improve the continuity and stability of production.

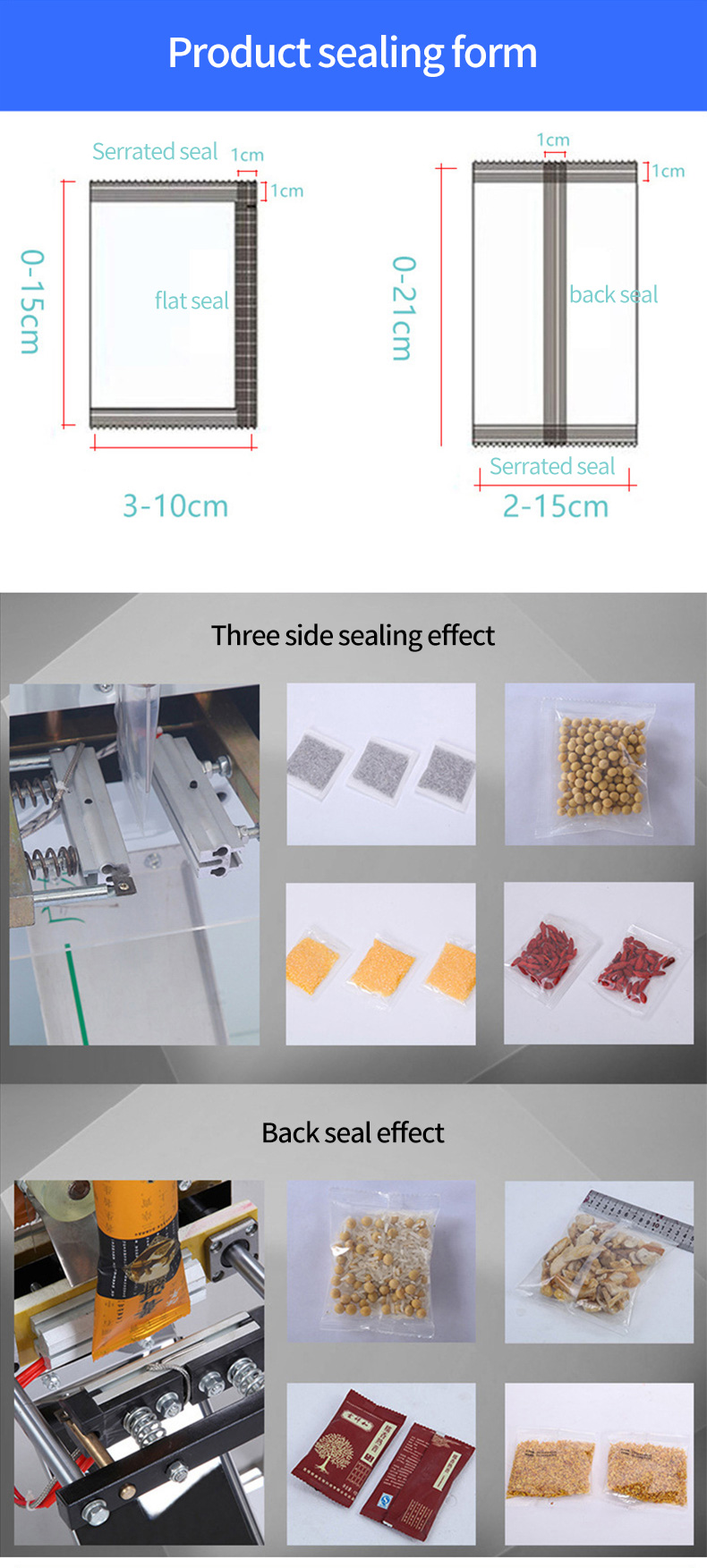

5. It can package both granular materials and powdered materials, and can also adjust the packaging parameters according to the characteristics of the materials, such as fluidity, viscosity, density, etc.

As an excellent equipment in the field of modern packaging, Multifunctional Granule Powder Packaging Machine combines cutting-edge technology and exquisite craftsmanship, and is specially designed to meet the complex packaging needs of granules and powder materials.

High-precision metering devices combined with automatic calibration technology ensure long-term stability and accuracy of packaging material quantity, avoiding product quality fluctuations and cost out-of-control caused by metering deviations.

Product Name: Packing Machine

Rated voltage: 22V (can be changed to 110V)

Product model: JK-S20

Packaging speed: 13-20 packs/min

Product material: stainless steel

Product size: 43*51*140cm

Product power: 500W

Machine weight: 60 kg

Product function: packaging

Application range: grains, seeds, traditional Chinese medicine powder, medicinal materials and other granular powders

It can freely shuttle between the two major material fields of granules and powders. Whether it is grains with excellent fluidity, fine drug powders, or chemical powders with slightly stronger viscosity, perfect packaging can be achieved through fine parameter adjustment.

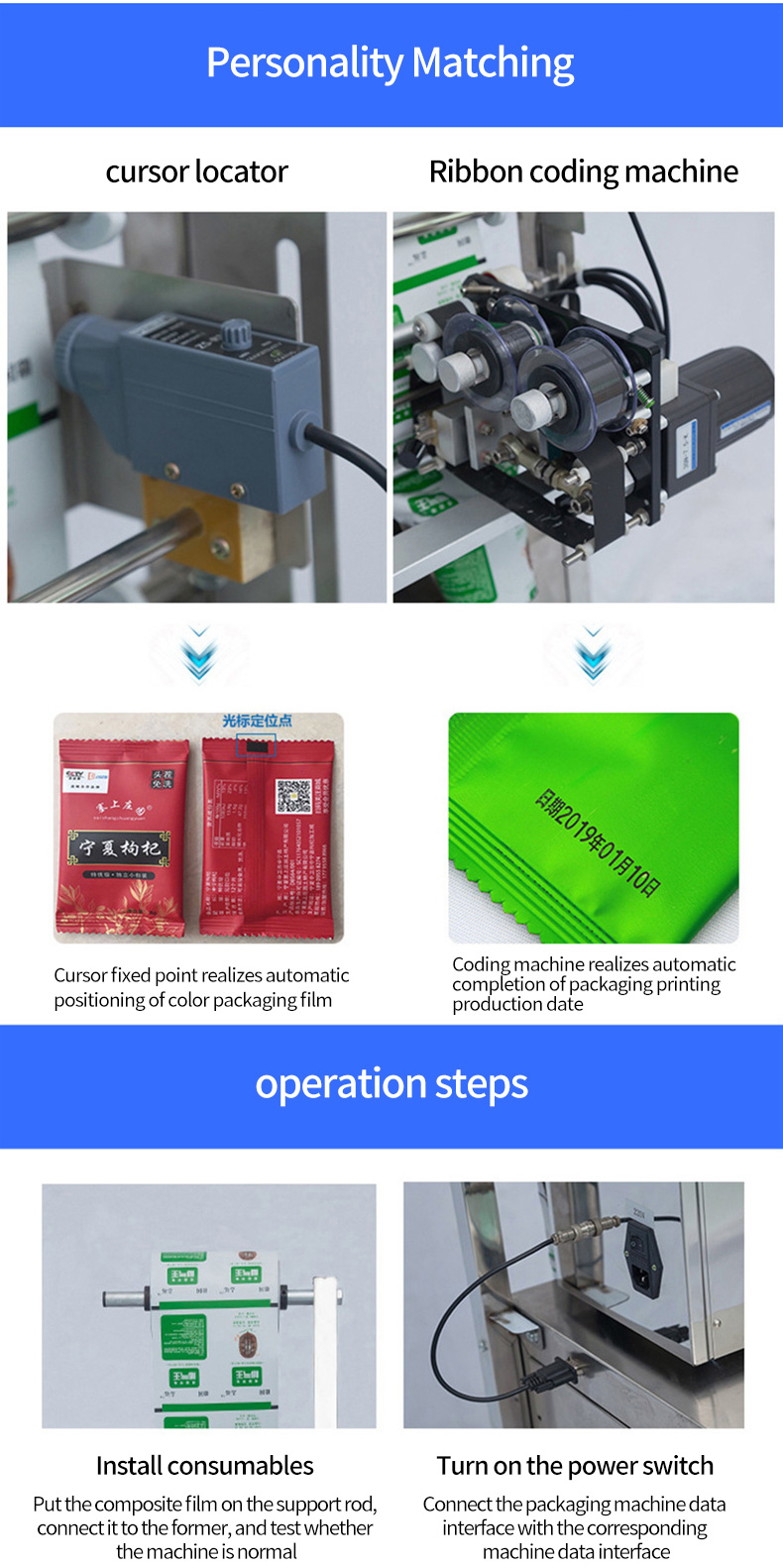

A wide variety of bag types, combined with customized services, make product packaging fit the market trends and customer personalized demands, and enhance product recognition and market competitiveness.

High-speed and stable packaging performance helps enterprises seize the initiative in fierce competition, reduce labor and time costs, quickly respond to market order demands, and achieve increasing scale benefits.

Multiple safety protection facilities build a solid safety line, and emergency stop, safety light curtain, and overload protection are all available to fully protect the personal safety of operators and meet the requirements of safety production regulations.

Select high-quality materials to create key components, coupled with strict quality control processes, to ensure long-term stable operation of the equipment and reduce the frequency of fault repairs.