M type wrapping machine

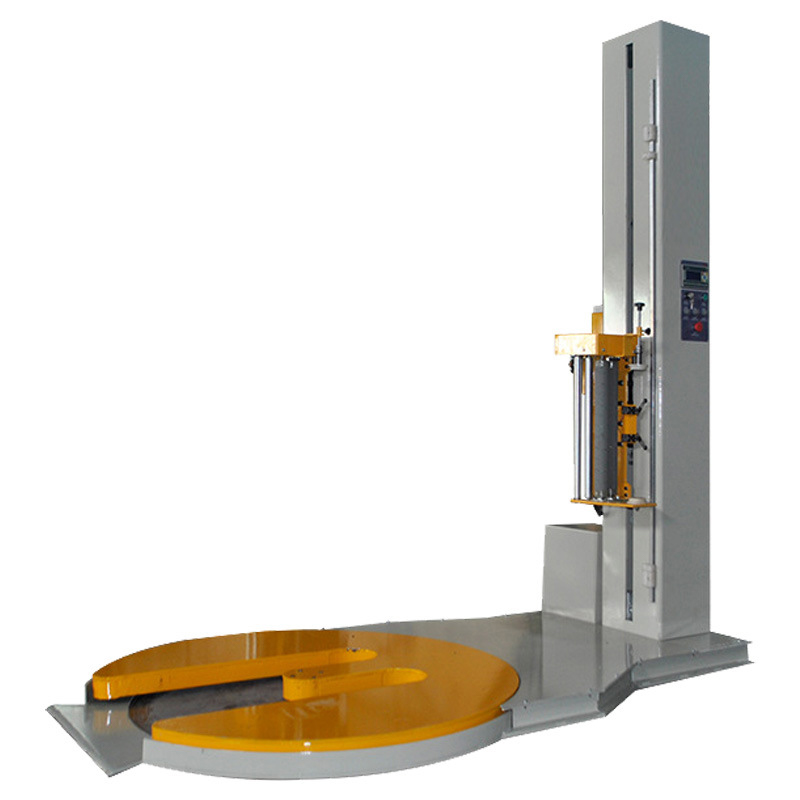

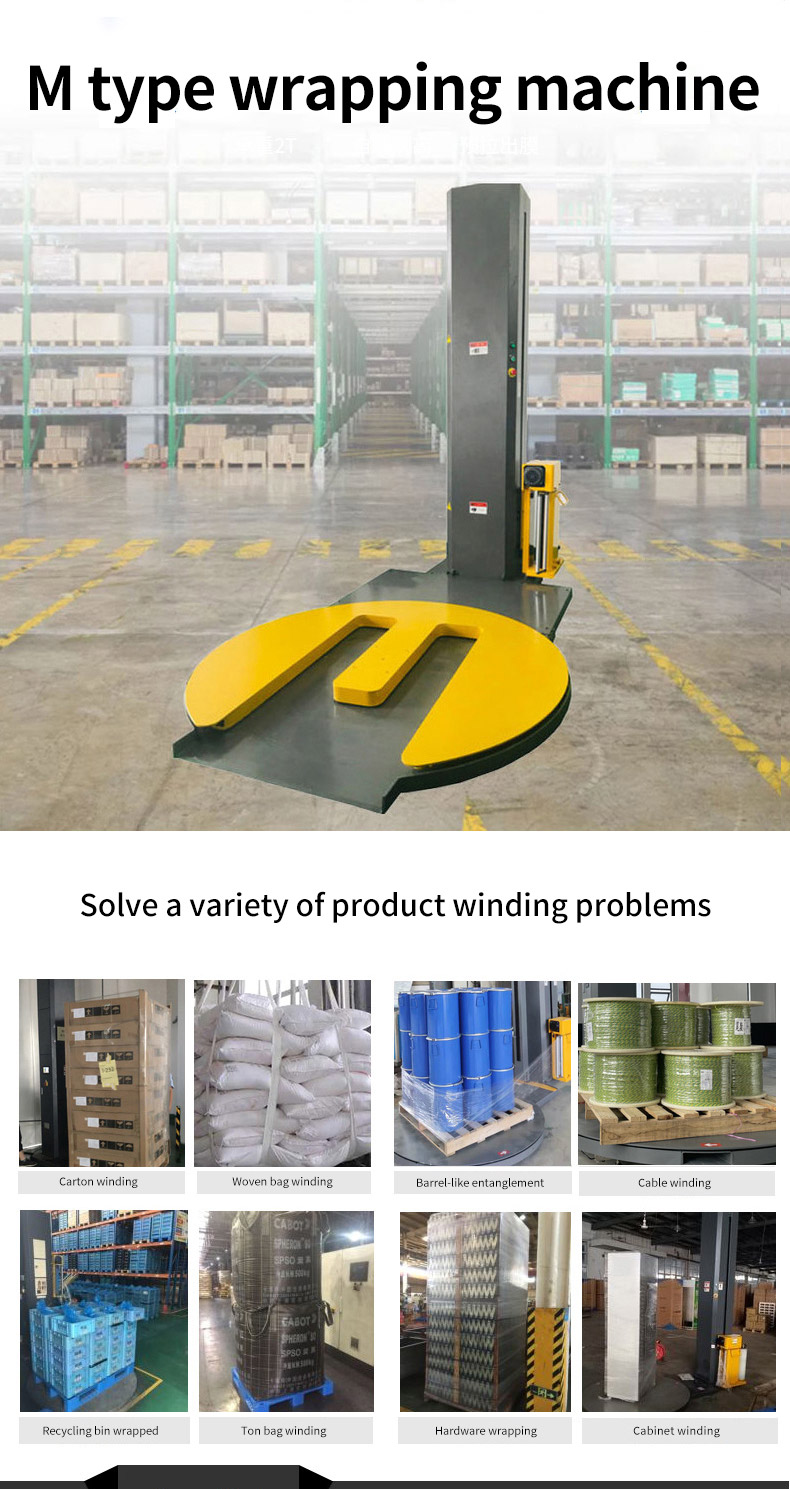

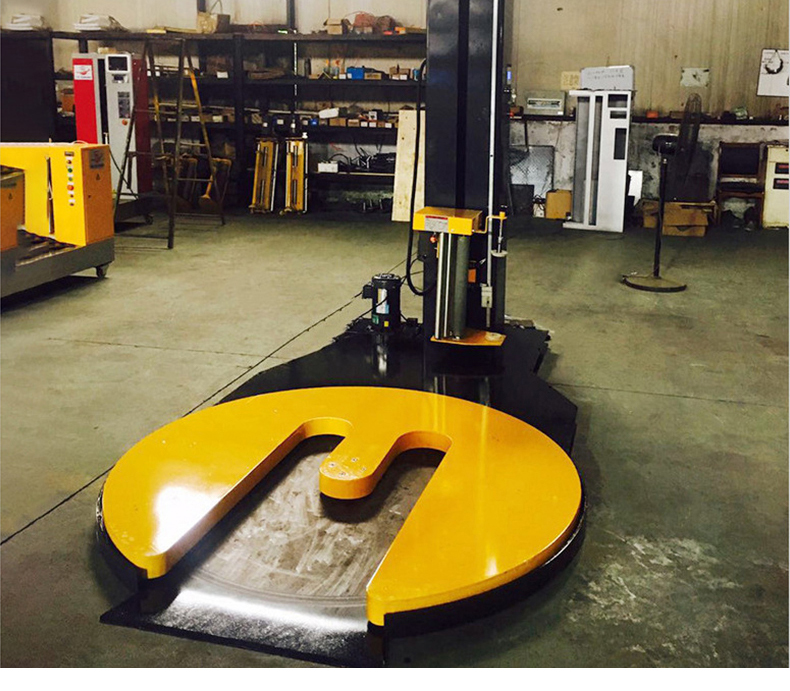

1. The M-type chassis design makes the machine compact and occupies little space, which can adapt to the layout of different sites.

2. The bottom of the turntable is usually equipped with a forklift slot, which is convenient for the forklift to directly fork the goods onto the turntable for packaging operations, and the turntable can be automatically reset.

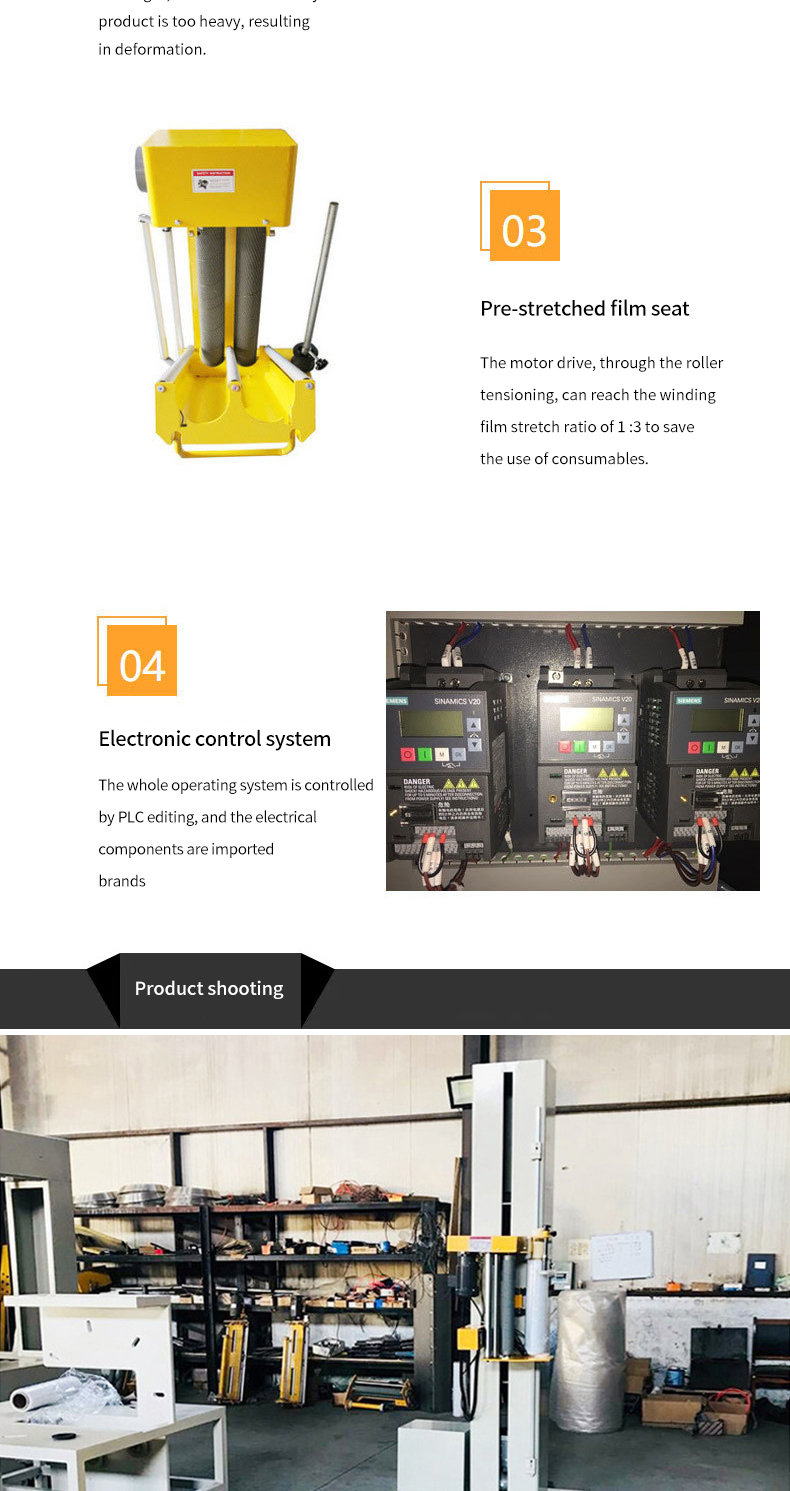

3. Through the adjustable pre-stretching system, the stretch ratio of the wrapping film can be as high as 250%-300%, tightly wrapped on the surface of the goods.

4. The PLC programming control system is adopted, and the parameters can be flexibly set according to different shapes, sizes and packaging requirements of the goods.

5. Equipped with advanced sensors such as photoelectric switches, it can automatically track the height of the packaging and realize the automatic lifting of the film rack.

The M-type wrapping machine is a widely used and high-performance equipment in the packaging field. It integrates advanced mechanical design, automatic control technology and efficient packaging technology to provide reliable, stable and flexible packaging solutions for various products.

Carefully crafted from high-quality steel, it offers exceptional strength and stability. This unique design allows the machine to evenly distribute the load during operation, even when handling heavy or high-center-of-gravity cargo.

As a key component for carrying goods for wrapping and packaging, the turntable adopts high-precision bearings and drive devices to ensure that its rotation process is stable, smooth and without jamming.

The film rack is compact and sturdy, and can stably install wrapping film rolls of various specifications. The film rack has a convenient way to load and replace the film.

The lifting system uses precision screw drive or hydraulic drive technology to achieve precise vertical lifting of the film frame. The wrapping system is driven by a high-performance motor to rotate the rotating arm or turntable to achieve circular movement of the wrapping film around the goods.

The M-type wrapping machine is equipped with an advanced programmable logic controller (PLC) as the core control unit, which combines high-precision sensors with an intuitive human-computer interaction interface to build a highly intelligent control system.

The control system integrates a variety of high-precision sensors, such as photoelectric sensors for detecting the position and height of goods, pressure sensors for monitoring the tension of the stretch film, encoders for accurately measuring the movement position and speed of the rotating arm or turntable, etc.