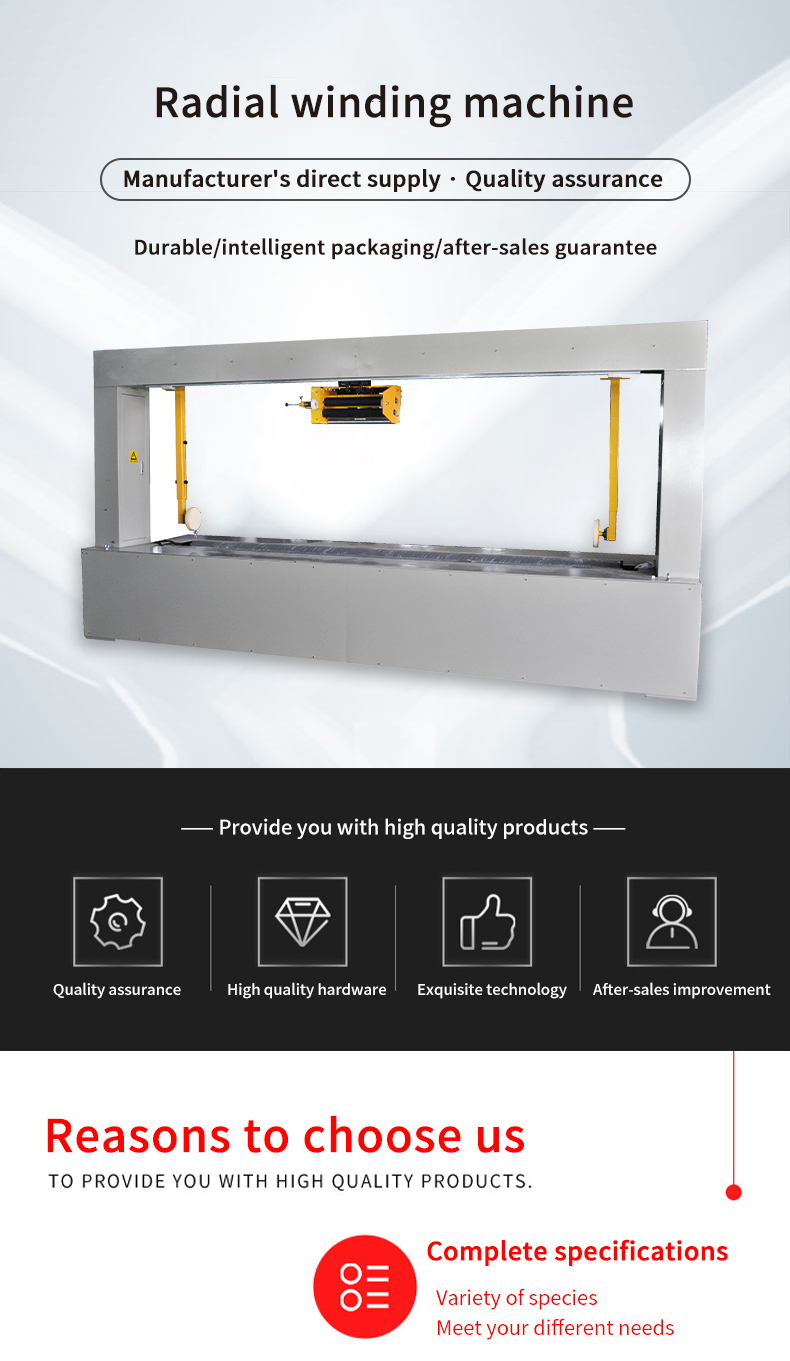

Horizontal cylindrical wrapping machine

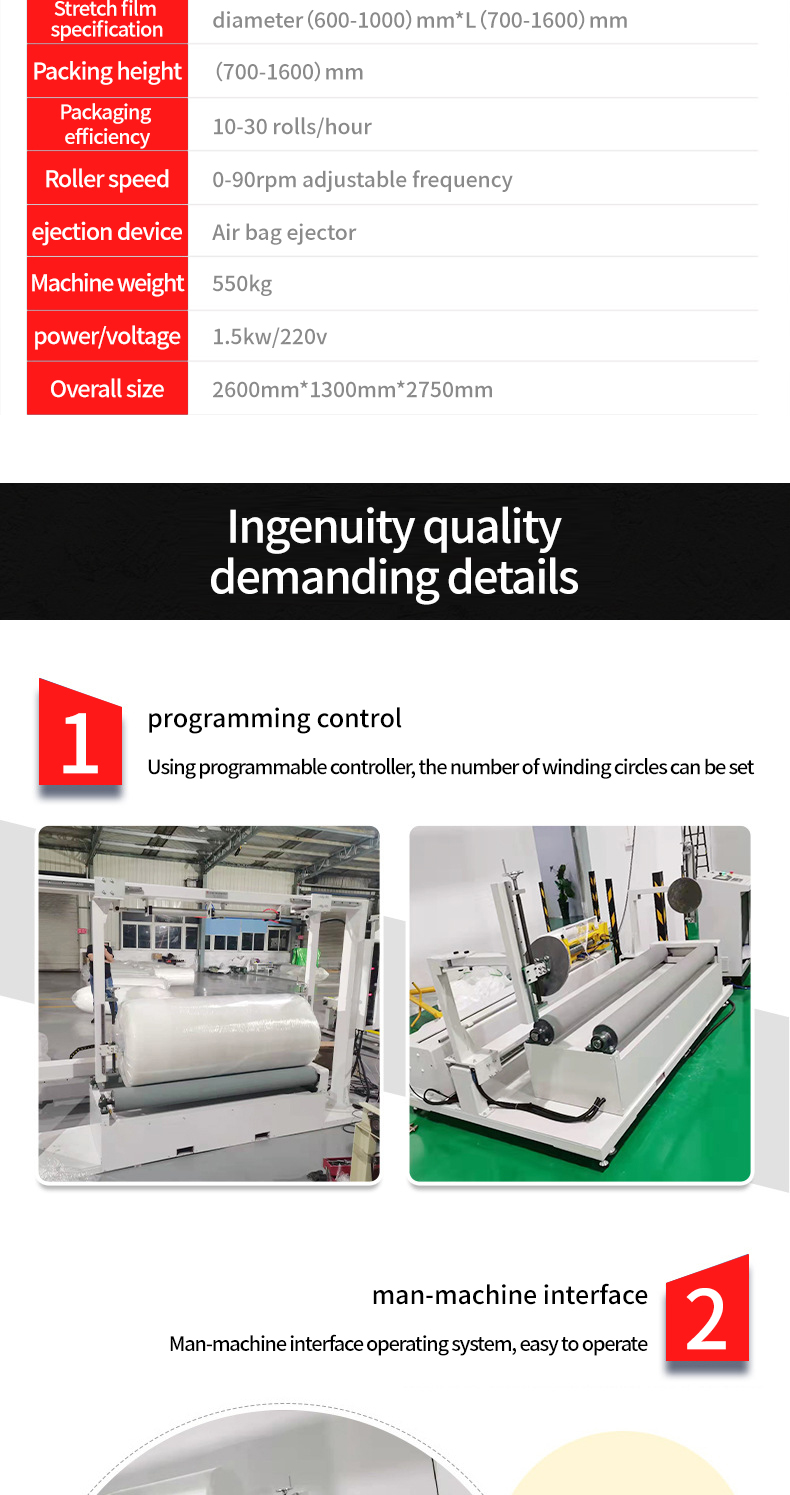

1. The product can be tightly wrapped in the film to form a stable package, which can effectively prevent the product from being damaged due to shaking and collision during transportation and storage.

2. Through precise sealing technology, good sealing can be achieved to prevent external factors such as dust and moisture from entering the interior of the package.

3. Make the appearance of the packaged products neat and unified, and enhance the overall image and attractiveness of the product.

4. With high packaging speed, it can complete the packaging task of a large number of products in a short time, significantly improving production efficiency.

5. Able to adapt to product packaging of various shapes, including cylindrical, square, oval and other regular shapes as well as irregular-shaped products.

Horizontal Cylindrical Wrapping Machine is an advanced equipment specially designed for efficient and accurate packaging of cylindrical products. It integrates modern mechanical design, automatic control, packaging material application and other technologies.

The sturdy main frame welded with high-strength steel ensures the stability and reliability of the equipment when running at high speed and bearing heavy loads.

High-performance AC servo motors are used as the main power source to drive the rotation of the slewing arm, the lifting of the film frame, and the transportation of the film.

Based on a programmable logic controller (PLC) as the core controller, it runs specially developed wrapping machine control software.

It adopts advanced intelligent film tension adaptive control system, which monitors the tension change of film in real time through high-precision tension sensor and feeds the signal back to the control system.

With the help of advanced motion control algorithms and high-precision servo motors and drivers, high-precision control of the rotational motion of the slewing arm is achieved.

Equipped with a quick mold change device and product size adaptive technology, it can complete the replacement of molds for different products in a short time and automatically adjust the packaging parameters and the working status of the equipment according to the size of the product.

It supports remote monitoring and fault diagnosis functions. Through the Internet of Things (IoT) technology and cloud platform, users can remotely monitor and manage the operating status of the horizontal cylindrical wrapping machine through terminal devices such as computers, mobile phones or tablets anytime and anywhere.

Users can easily set and accurately control various packaging parameters through the touch screen operation interface, such as the number of winding layers, the overlap of each winding layer, film tension, the rotation speed of the swivel arm, the lifting height of the film rack, etc., to ensure the consistency and stability of the packaging effect.