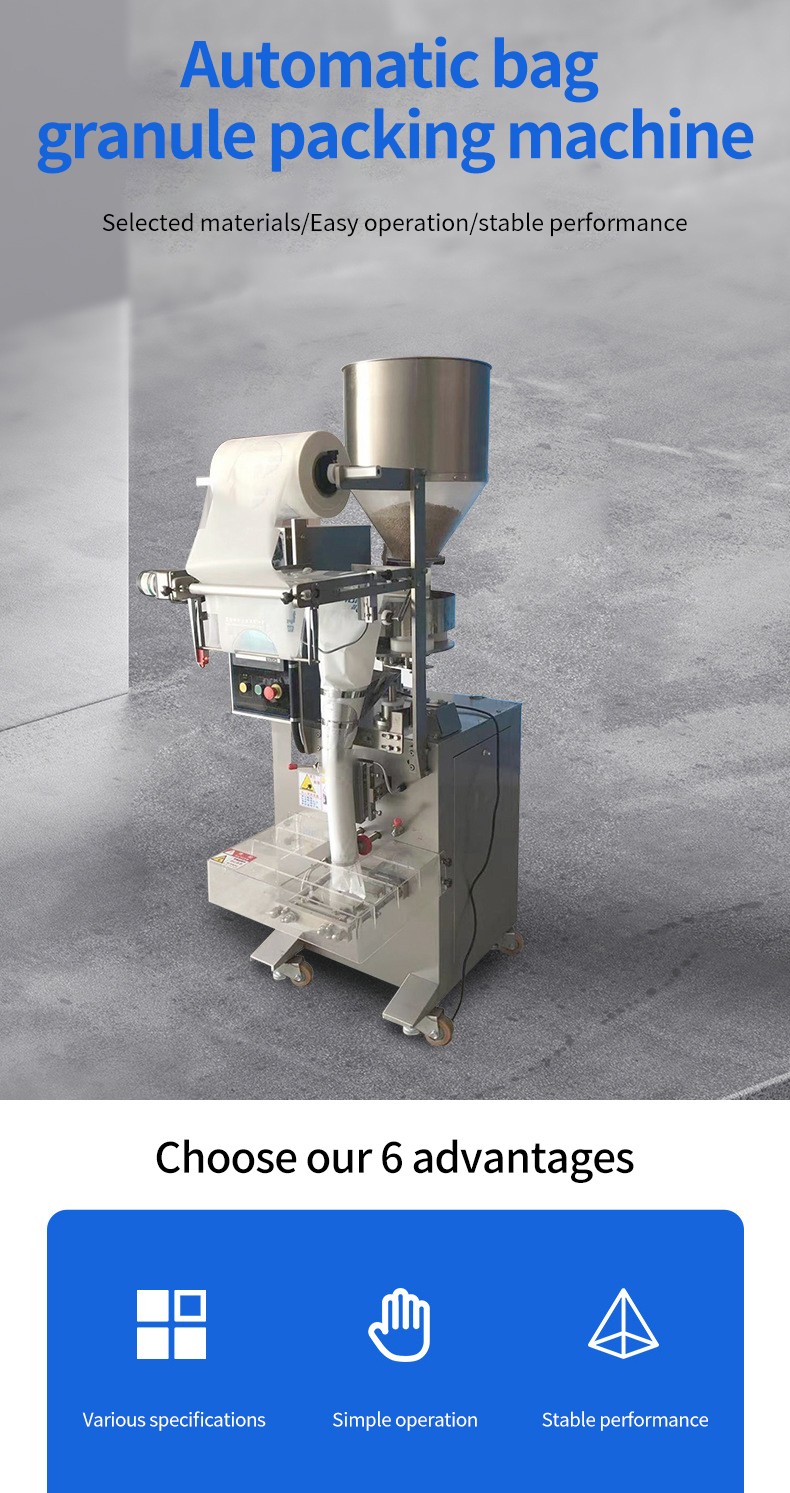

Fully automatic granule packaging machine

1. It can automatically complete a series of packaging processes such as material conveying, metering, filling, sealing, coding, counting, etc.

2. It basically does not require manual tedious packaging operations, reducing dependence on manpower, thereby reducing the labor costs of the enterprise.

3. It adopts advanced weighing systems, metering devices and control systems, which can accurately weigh or count granular materials.

4. The equipment has high stability and can maintain consistent packaging accuracy during long-term operation, thereby ensuring the stability of product quality.

5. It can be applied to the packaging of various granular materials, chemical fertilizers, plastic particles, washing powder, etc., and only needs to make simple adjustments to the equipment according to the characteristics of different materials.

The fully automatic granule packaging machine is a highly efficient packaging equipment that integrates multiple advanced technologies such as mechanics, electronics, and pneumatics. It is specially used for the automatic packaging of various granular materials. It can accurately complete a series of packaging processes such as metering, filling, sealing, and coding.

The hopper is made of stainless steel, which has good corrosion resistance and hygiene. It can hold a certain amount of granular materials to ensure the continuity of the packaging process.

Bag size:Width :30-130 mm Length:30-170 mm

Productive capacity:30-60 bags/min

Measuring range:3-150ml (can be customized)

Gross power:220V/50HZ1.4KW

Machine weight:300KG

External dimension:(L x W x H) 900x1100x1900 mm

The bag maker makes the flat packaging film into bags of various shapes according to the packaging requirements. The sealing device adopts heat sealing technology, using heating elements to heat and melt the sealing part of the packaging film and press them together to form a firm seal, ensuring the sealing and moisture-proof properties of the packaging.

Different types of coding devices can be configured according to customer needs, such as thermal transfer coding machine, inkjet coding machine or laser coding machine.

Operators can intuitively set packaging parameters such as packaging weight, quantity, speed, sealing temperature, coding content, etc. through the HMI, and monitor the operating status of the equipment in real time.

The machine body adopts a solid metal frame structure, which is usually welded from high-quality steel and has sufficient strength and stability to withstand various vibrations and impacts during the packaging process.